The critical role of material selection in preventing diaphragm seal failure

Diaphragm seals are critical in protecting pressure transmitters. Selecting the correct material and/or coating can extend the life of the diaphragm and make a difference to the longevity of the transmitter. This is especially true if the transmitter is used in harsh or challenging applications. Since the transmitter sensing element needs to be in contact with the process fluid, there is a high risk of failure due to corrosion, mechanical damage to the isolating diaphragm, or loss of sensor fill fluid.

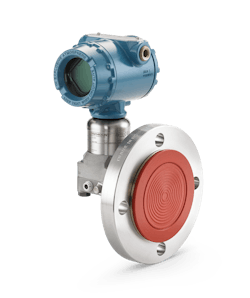

The right diaphragm seal can help prevent those issues without affecting the measurement readings. In addition, the diaphragm seal eliminates the need for impulse lines that are susceptible to plugging from suspended solids or viscous fluids. Diaphragm seals are available on both inline and coplanar pressure transmitters and serve both to protect the transmitter and allow connection to a wide variety of unique process connections for pressure and level measurement.

Every plant manager wants to avoid unscheduled downtime and ensure the safety of the employees and facility while still meeting projected process output goals. A ruptured transmitter isolation diaphragm will result in inaccurate measurements that affect the process and quality of the end product, which ultimately affects the facility's overall productivity and profitability. Diaphragm seals reduce the risk of damaging transmitter isolation diaphragms by providing a barrier between the process fluid and the sensing element. Diaphragms seals allow measurement on applications that would not be possible for a standalone transmitter.

Different applications that affect diaphragm seals

Industries ranging from chemical and hydrocarbon processing to pharmaceutical and food and beverage use differential pressure (DP) or static pressure measurement as part of their process; they are proven technologies and appropriate for a wide variety of applications. However, it is important to select the diaphragm material most suited to the application and the fluids that it may be exposed to in the process.

Diaphragms are thin and flexible in order to be sensitive to changes in pressure. However, there are some applications where even selecting a well-suited diaphragm material is not enough to protect the diaphragm from damage. In those cases, there are several diaphragm coating options that help protect the diaphragm.

Some of the extreme conditions and specialty applications that require a diaphragm seal are as follows:

Extreme temperatures can affect the pressure instrument if it was to come into direct contact. Extreme temperatures are process temperatures above 205ºC and/or ambient temperatures below -45ºC. It is relevant to mention both process temperature and ambient temperature because both affect the diaphragm seal system performance. Emerson’s Rosemount 3051S Thermal Range Expander can handle hot processes up to 410ºC with cold ambient conditions.

Corrosiveapplications have process fluids that can gradually destroy the diaphragm material. Such process fluids are used in the chemical industry and can be either a single chemical or a mixture — each with its own corrosive properties. In this industry, finding a compatible diaphragm material can be a process of trial and error, depending on the chemicals in the process fluid. When exotic diaphragm materials have failed, the diaphragm can benefit from a corrosion-resistant PFA coating that slows the process fluid from reaching the diaphragm, enhancing the corrosion resistance.

Abrasive processes are similar to corrosive applications in the damage they do to a diaphragm, but in this case, the damage is caused by particulate matter in the process fluid. Anything at least the size of a grain of sand can abrade a surface. There are diaphragm materials that are harder and more resistant to abrasion. When those are not enough, a hard-carbon nanostructured coating can enhance the diaphragm's durability. This is most often seen in the pulp and paper and mining industries.

Viscous processes, or fluids that are solids-laden, can build up on the diaphragm, reducing the sensitivity to pressure changes, potentially blocking the pressure from reaching the diaphragm. Viscosity is also affected by temperature changes, which means a diaphragm might perform well until there is a significant temperature change in the fluid.

Hygienic applications are processes that must have process connections that are easy to clean and designed to prevent contamination, specifically those found in pharmaceutical production as well as in the food and beverage industry.

Vacuum applications are less common and only apply to applications operating at less than 6 psia (400 mbar-a). It is important to use a diaphragm seal system fill fluid designed for vacuum applications that has gone through additional processing for optimal performance under vacuum.

Hydrogen permeation is the process where hydrogen atoms diffuse through the diaphragm and unite to form molecular hydrogen. Molecular hydrogen is too large to permeate back through the diaphragm; it becomes trapped and forms hydrogen bubbles in the fill fluid. The presence of hydrogen gas bubbles can severely affect performance. Adhering a thin layer of gold to a base metal will provide protection against hydrogen permeation. Gold plating is suggested in applications where atomic hydrogen is present.

From the field

A leading refiner and distributor of oil needed to accurately and reliably monitor pressure inside coker drum charge lines to give an early indication of plugging.

The refinery opted for a Rosemount 3051S Thermal Range Expander that employs two fill fluids in a single system (as shown in Figure 3). The fluid at the process seal is rated for high temperatures and runs a short distance to an intermediate seal with a second fill fluid rated for ambient temperatures. This second fill fluid then connects to the process sensor. This eliminates the need for heat tracing altogether. Using this dual seal solution, the measurement swings that the refinery had seen in the past were eliminated, ensuring reliable coker drum charge pressure measurement. The solution also reduced the risk of plugging of the lines and saved the refinery more than $20,000 per year in transmitter replacements.

Ian Kugel is the global product engineer for Rosemount diaphragm seal systems at Emerson. He has a Bachelor of Science in mechanical engineering from the University of Minnesota. Kugel is responsible for incorporating the voice of the customer in new product development, serving as the subject matter expert for remote seals, and publishing/maintaining all related product documents.

Ian Kugel

Ian Kugel is the global product engineer for Rosemount diaphragm seal systems at Emerson. He has a Bachelor of Science in mechanical engineering from the University of Minnesota. Kugel is responsible for incorporating the voice of the customer in new product development, serving as the subject matter expert for remote seals, and publishing/maintaining all related product documents.