No matter whether consumers choose a pilsner, an ale or another popular type of beer, there is a critical focus at nearly all breweries today on their production process energy (natural gas) costs and plant environmental compliance (waste gas emissions). Failing to pay attention to the efficiency of these processes at breweries or any other type of food and beverage processing plant can lead to cost competitiveness issues and hefty regulatory fines.

Today’s modern breweries must not only produce a popular and refreshing product, but also continuously reduce costs and their carbon footprint by tightly controlling natural gas usage, residual CO2 levels and mixed waste gases. From fermentation vessel natural gas heating to waste gas recovery for co-gen electric power or combined heat and power (CHP) systems to stack flaring, the emphasis is on process efficiency and protecting the environment.

The challenges

The plant team at a large craft brewery in Southern California’s San Diego County contacted Fluid Components International (FCI) with concerns about its twin goals of reducing natural gas consumption (cost) while also lowering its waste gas emissions. Electric and natural gas energy costs in California are among the highest in the nation. The state is also well-known for its environmental regulations, which can exceed national standards and those of many other states.

According to a report published by the American Brewing Association, “There are many best practices for energy efficiency and conservation that can be easily incorporated into daily operations, as well as solutions that can reach beyond greenhouse gas (GHG) reduction and lead to operating cost reductions, additional sources of income, and new community initiatives. These solutions help brewers save money and become industry leaders in sustainable practices.”

A guide produced by the American Brewing Association estimates the average energy input cost per barrel of beer from a craft brewer ranges from $3.34 to $4.26 each barrel. A craft brewer’s energy cost is higher than larger industrial-type breweries.

How to control the burn

There is one thing that all brewers have in common when it comes to controlling natural gas consumption and waste gas management. Whether they are micro, craft or large industry giants, all breweries depend on accurate and consistent air, natural gas and waste gas flow measurement instrumentation that must function under rugged and variable demand conditions. What is not accurately measured cannot be controlled to optimize brew house process efficiency.

Four key factors

To reduce natural gas consumption, it is important that brewers and other plant engineers know and control the calorific value of the natural gas input of their gas feed for their boilers to produce steam used for heating brew kettles and to make hot water. To reach this goal, there are four key factors that plant engineers must consider when optimizing all heating processes involving brew kettles, boilers, etc.

1. Process stoichiometric burn ratio

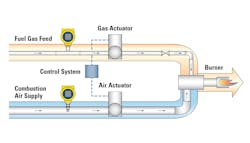

The stoichiometric point in well-controlled natural gas-fired processes is where the mixture of fuel to air is optimal. Too little air, and the burner fire does not achieve its full calorimetric heating potential, and natural gas is wasted when it takes longer than necessary to achieve and sustain the required heating levels for vessel burners or steam boilers (Figure 2).

When the fuel mixture is too air-rich, then there is the potential for excess nitrogen oxide (NOx) emissions, which are a highly reactive gas and toxic pollutant. NOx often appears as a brownish gas. It is a strong oxidizing agent and plays a major role in the atmospheric reactions with volatile organic compounds (VOCs) that produce ozone on hot summer days.

2. Effects of gas composition

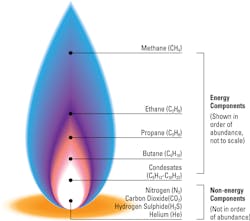

Natural gas composition (Figure 3) differs somewhat around the world, as well as seasonally in very cold winters and hot, humid summer conditions. The primary energy components of natural gas are methane, ethane, propane, butane and condensates. The non-energy components are nitrogen, carbon dioxide, hydrogen sulfide and helium.

The mix of these components can affect gas density, the calorific value and then, in turn, plant instrumentation. Some thermal flow instruments, however, are available with multiple calibration groups, which can automatically switch seasonally or any time as inline gas analyzers indicate changes in the gas mixture to assure the proper air/gas ratio is maintained for heating efficiency.

3. Process variability — turndown range

Brewery and other food or pharmaceutical batch processes often operate at variable levels of production, which means the amounts of natural gas required for heating are also variable. Some of the reasons include processing multiple products on the same line, seasonal demand, washdown cycles, planned maintenance, shift changes, etc.

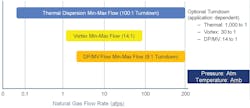

For the most accurate gas and air flow measurement, a laboratory-like steady-state flow is generally the easiest to measure. That is why, in the real plant world, it is important to understand the potential full flow range of the gas to be measured — also known as turndown range — from the lowest to highest flows and if the flow measurement accuracy expected will be available over the entire flow range (Figure 4).

4. Flowmeter accuracy and repeatability

In order to achieve the desired flow measurement accuracy level with confidence, the process or plant engineer must define the required process flow range, the desired flow measurement accuracy and the expected turndown ratio. For example, some processes require a rapid startup with initially fast heating and then revert to a much lower steady-state or standby function in between batches. The speed of these changes in gas flow can affect measurement accuracy.

The major natural gas flowmeter technologies available — Coriolis, differential pressure, thermal, ultrasonic and vortex — all vary in specified accuracy from ±0.5% and up depending on their turndown ranges from 1,000:1 to 8:1 (depending on sensing technology). For natural gas heating, thermal flow sensing offers the advantages of a broad flow range, wide turndowns and accuracy to ±0.75%.

Solutions for brewers

For the San Diego County brewer and others concerned about natural gas cost control and waste gas emission levels, the ST75 Series Flow Meter from FCI was a simple decision (Figure 5). It optimizes their complex fermentation tank steam heating processes by accurately measuring the ratio of boiler burner fuel gas to air for the most efficient combustion to lower gas consumption costs and emissions.

The CO2 gas that is also naturally produced during the brewing process, and any additional CO2 gas necessary for finishing the beer, also requires accurate flow measurement. Thermal flowmeters such as the ST75 with rugged, dependable thermal dispersion technology are designed specifically for these small line size processes — from 0.25 inches to 2 inches.

The San Diego County brewer’s plant team was pleased with how the ST75 operates over a wide flow range, from 0.01 SCFM to 559 SCFM (0.01 NCMH to 950 NCMH). For their variable process conditions, the process engineers appreciated the ST75's wide turndown range, which can be preset by the factory from 10:1 to 100:1, with optional higher ranges available on request.

Offering built-in temperature compensation, the ST75 maintains consistent performance in rugged, hot industrial environments. The brew house’s engineers concluded that the meter’s standard accuracy to ±1% of reading with ±0.5% repeatability over varying temperatures would be adequate to achieve their process cost control improvement goals.

With a Vortab Flow Conditioner added as a spool piece, the models ST75V or ST75AV meters are ideal for brew house installations with limited straight-runs and/or for operating in transitional flow ranges with accuracy of ±1% reading, ±0.5% full scale. Again, the brewer’s plant team appreciated the flexibility of the flow conditioner option for its pre-existing equipment layout.

Ideal for fermentation vessels or tanks, ovens, heat chambers and furnaces, the ST75 features remote mounting capabilities for hazardous or crowded plant environments and includes major global Ex safety approvals. The remote-mount transmitter, including a digital display, can be mounted 50 feet away from its flow sensor in the process piping and connected via two 0.50-inch FNPT or M conduit connections. The meter’s fully scalable dual 4-20 mA standard outputs are user assignable to flow rate and/or temperature and a 0-1kHz pulse output of total flow. The instrument can be ordered for input power with either 18 to 36 Vdc or 85 to 265 Vac, with or without a built-in LCD digital display.

Offering direct-flow measurement, the thermal meter eliminates costly additional pressure and temperature sensors, flow computers or other devices that are required with orifice plates, Venturis, Vortex and other volumetric meters. The meter also requires virtually no maintenance for a low life-cycle cost, gaining the attention of the cost-conscious brewer’s plant team.

Conclusion

Energy efficiency goals set by brewers and other food and beverage processing plants typically start with monitoring energy bills. Sooner or later, however, the setting of key performance indicators (KPIs) migrates down to the process instrumentation level to flowmeters in the brew house.

Achieving heating process efficiency improvements cannot occur without more accurate, reliable flowmeters to control the burn. This brewer’s plant team, like many others that rely on natural gas heating, is finding that upgrading to thermal flowmeters pays for itself and keeps the energy cost savings flowing to drive future profits and dividends while protecting the planet.

Steve Craig is a senior engineer at Fluid Components International (FCI).