Accurately measure two-phase fluids with entrained gas

Over the past few decades, process manufacturers in a variety of industries have widely adopted Coriolis flowmeters for measuring mass flow, volumetric flow and density in applications where accuracy is paramount. These devices achieve this with fine-tuned drive coils and phase shift detectors to translate vibrations to corresponding process values. However, like every industrial tool, there are some natural caveats to Coriolis meters’ utility.

Entrained gas bubbles in liquid media are an Achilles’ heel for flow measurement, typically resulting in measurement inaccuracies, and Coriolis instrumentation is not immune. For example, entrained gases can be minimized through clever application design, but complete negation can be impossible or even undesirable, as in the case of certain food and beverage products that contain gas for texture and other reasons.

Fortunately for process manufacturers, new advancements in Coriolis meter technology address entrained gas measurement and other challenges. This article describes the fundamentals of Coriolis flowmeters and the mechanics of entrained gas, discusses methods for overcoming entrained gas challenges and presents a success story from the dairy industry.

Coriolis flow difficulties with entrained gas

Coriolis meters consist of one or more measuring tubes, each oscillating via an artificially induced pulse from an exciter. As fluid flows through each tube, its inertia imposes additional twisting, changing the oscillatory pattern. Two detectors — upstream and downstream of the exciter — distinguish this phase difference, which directly correlates to mass flow (Figure 1).

The oscillation frequency can also determine fluid density, and the sensors measure temperature to compensate for thermal influences. These sensors do not require inlet or outlet straight pipe runs, increasing installation versatility over other flow measurement methods.

With two-phase process fluids, Coriolis mass and density measurements represent the combined liquid and entrained gas, making it impossible for conventional Coriolis meters to measure the liquid alone. This causes mass flow and density measurement errors, further compounding when converting these values to volumetric flow.

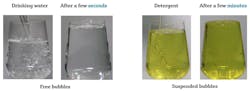

Entrained gas bubbles can be classified as either free bubbles or suspended bubbles. Free bubbles move easily and independently through a fluid as the flow tube vibrates, and they typically cause mass and density undermeasurement. Conversely, suspended bubbles are held in place within a fluid and are alternately compressed and expanded as the tube vibrates, acting as springs that exert additional force on the tube walls, which can result in overmeasurement (Figure 2).

Thoughtful application design can minimize the negative impacts of entrained gas on Coriolis measurement to some extent. For example, applied backpressure, high inlet tank levels, fluid splash mitigation, air eliminators, settlement tanks and vertical upward Coriolis flowmeter installations all help limit bubbling and resultant entrained gas formation.

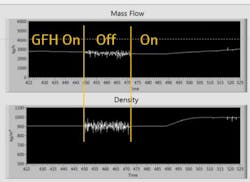

Additionally, software solutions such as Endress+Hauser’s Gas Fraction Handler, included with all Promass 300/500 Coriolis flowmeters, can dampen the influence of entrained gas on measured values while providing diagnostic data regarding bubble type and severity. When two-phase flow is detected, the software filters measured flow values to prevent severe fluctuations (Figure 3).

Under single-phase conditions, filtering is disabled to avoid dampening or slowing down measurement response. The software provides Index Inhomogeneous Medium and Index Suspended Bubbles diagnostics, which indicate the approximate concentrations of both free and suspended bubbles in the process fluid.

While application design and software solutions can reduce the presence or negative impacts of entrained gas in some applications, they cannot eliminate the measurement issues found with suspended bubbles in viscous fluids, nor can they help in applications where gas is intentionally added, such as in ice cream and other dairy production.

Overcoming entrainment challenges with multi-frequency technology

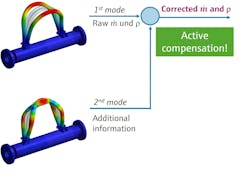

With standard Coriolis meters, vibrating tubes are driven at the fundamental resonant frequency of the combined tube/fluid system. However, Endress+Hauser Coriolis flowmeters with multi-frequency technology (MFT) also drive the tubes at their second and third natural modes to obtain additional information about the fluid’s vibrational properties (Figure 4). This substantially increases the accuracy of density and flow measurements in fluids with suspended gas bubbles.

Entrained gas influences the fundamental and auxiliary resonance modes differently, and analyzing multiple modes together enables identification of entrained gases’ unique properties so measurement can be compensated accordingly.

Metering challenges in the dairy industry

Producers of dairy products — including milk, cheese and ice cream — regularly measure the inflow of raw milk and outflow of finished products for custody transfer, internal accounting and plant mass balance purposes. These measurements are often performed by truck weigh scales, dipsticks or magnetic flow meters, but each method has drawbacks.

Truck scales are generally accurate enough for custody transfer, but they can be expensive, sometimes costing over $200,000 USD to procure and $5,000 on average each year to maintain. Replacing a single load cell can cost over $9,000; most truck scales have four.

In addition, the number of trucks that can be loaded or unloaded at a given time is limited, restricting plant throughput. Weigh scales also increase turnaround time for each truck delivery by 10 minutes on average, reducing the number of deliveries each truck can provide, as well as the amount of raw milk available for receiving.

Finally, truck scales require significant land footprints — around half an acre each — that could otherwise be available for profitable purposes, and rain or snow can influence weight readings, resulting in measurement errors and additional maintenance work to keep scales clear.

Compared to truck scales, dipstick readings and magnetic flowmeters are inexpensive and accessible, but these instruments are less accurate for dairy products, limiting their usefulness. Dipsticks commonly show 5-8% error, while magnetic flowmeters often overestimate by as much as 10% because they cannot compensate for entrained gas.

Effective dairy metering with MFT

Historically, the difficulties posed by entrained gas have limited the use of Coriolis mass flowmeters in milk metering because suspended microbubbles often form in milk during transit due to sloshing and during pumping due to cavitation. Air eliminators can remove larger air slugs but cannot eradicate these tiny bubbles (Figure 5).

Custody transfer applications have stringent accuracy standards of less than 0.2% uncertainty, and most Coriolis meters cannot perform to such a standard under these conditions. However, with the introduction of MFT, entrainment is no longer a prohibitive problem for certain Coriolis flowmeters, such as Endress+Hauser’s Promass Q.

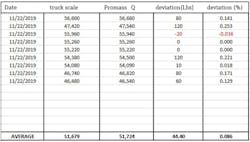

Comparisons of over 1,000 truckloads of raw milk between MFT meter and truck scale measurements exhibited an average deviation of less than 0.1%, well within the requirements for custody transfer certification (Table 1).

In some cases, a Coriolis flowmeter with MFT can be installed as-is in an existing receiving bay, but for new setups and receiving bays, complete turnkey receiving solutions are available. With increased throughput and reduced costs compared to truck scales, MFT meter-based systems can provide return on investment in as few as three months.

MFT in a German dairy

A German dairy producing semi-hard cheese, whey, skim milk concentrate and butter sought to improve mass flow measurement in raw milk receiving and mass balancing. The plant places a high value on accurate measurements because of the large amounts of raw milk it processes in everyday operations.

During truck transport, raw milk is constantly moving, resulting in aeration. At the point of delivery, the milk often consists of 10-20% air by volume, making it very difficult to measure its flow accurately. To overcome this challenge, the plant installed a new MFT-equipped Promass Q 300 Coriolis flowmeter, significantly improving measurement accuracy, despite the challenging presence of entrained gas.

In addition to the raw milk receiving bay, the plant installed an MFT Coriolis meter near the end of its production line to check mass balancing. This way, if an unusual discrepancy occurs anywhere in the process between received raw milk and outgoing product, staff can more quickly trace and troubleshoot the source rather than waste time wondering whether to dismiss the signal as an errant measurement due to entrained gas.

Improving operations with accurate fluid measurement

Gas entrainment makes flow measurement challenging, especially in applications with tiny, suspended bubbles that cannot be easily removed. But MFT equips Coriolis meters with the ability to make precise measurements, even in these demanding conditions.

This technology empowers processors in the dairy industry and beyond to improve metering reliability and reporting accuracy, subsequently easing maintenance and troubleshooting in addition to increasing profits to remain competitive.

Lauton Rushford is a national marketing manager for flow products at Endress+Hauser USA. He graduated from Purdue University in 2018 with a Bachelor of Science in nuclear engineering. Lauton joined Endress+Hauser shortly thereafter as an inside sales engineer. Throughout his five years with the company, he also held a regional industry management role focusing on solutions in the water and wastewater industry.

About the Author

Lauton Rushford

Marketing manager for flow products at Endress+Hauser USA

Lauton Rushford is a national marketing manager for flow products at Endress+Hauser USA. He graduated from Purdue University in 2018 with a Bachelor of Science in nuclear engineering. Lauton joined Endress+Hauser shortly thereafter as an inside sales engineer. Throughout his five years with the company, he also held a regional industry management role focusing on solutions in the water and wastewater industry.