The basics of thermal mass flowmeter technology

Measuring the movement of gases is critical in many industries. Inaccurate flow measurements can lead to waste, inefficiencies, loss of revenue and safety hazards. With so many types of flowmeters available, it can be challenging to select the right meter for the job.

Thermal mass flowmeters offer several advantages over other types, making them a popular choice for gas flow measurement in a wide variety of industries.

What are thermal mass flowmeters?

Thermal mass flowmeters, also referred to as thermal dispersion mass flowmeters or immersible thermal mass flowmeters, are versatile instruments for measuring the instantaneous mass flow and total mass flow rate of gases flowing through closed conduits, such as pipes or ducts.

Unlike flow instrumentation that utilizes volumetric flow technology, thermal mass flowmeters are unaffected by temperature or pressure fluctuations. They directly measure the mass flow, or actual number of gas molecules, to provide accurate flow measurement.

Basic principles of thermal dispersion technology

Thermal mass flowmeters use the principles of heat transfer to determine mass flow rates. At their core, these meters have two primary sensors:

- Temperature sensor: This element continuously measures the actual temperature of the gas flowing in the pipe regardless of flow velocity.

- Velocity sensor (heated sensor): This sensor is heated continuously via electrical wattage to a constant temperature differential that is always maintained between the two sensors.

- Gas molecules act like tiny heat transporters. As they flow past the heated velocity sensor, each molecule absorbs a small amount of heat and carries it downstream.

The corresponding cooling effect is measured and compensated for instantaneously by the instrument's sensor drive electronics, which instantly add more heat to the sensor to maintain that constant temperature differential. The amount of heat required to maintain the constant temperature differential is directly proportional to the cooling effect of the gas molecules flowing by the sensor. This allows the sensor to calculate a mass flow measurement.

Components of thermal mass flowmeters

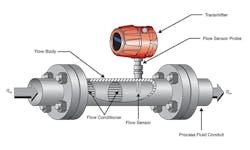

Thermal mass flowmeters encompass several essential components:

Flow body: The physical pipe or chamber which the fluid (often gas) flows through. The flow body is often made from durable materials like stainless steel, specifically chosen to be compatible with the process gas.

Transmitter: This electronic device serves as the meter's "brain." It processes sensor signals, calculates mass flow, applies calibration factors, handles sensor diagnostics and communicates data to external systems.

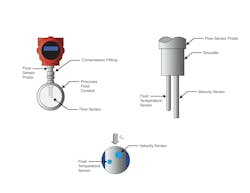

Flow sensors: Typically, there are two sensors: a heated or velocity sensor that is heated to maintain the constant differential temperature and a temperature sensor that monitors the temperature of the gas flow.

Process fluid conduit: This refers to the pipe, duct or channel where the gas flow is being measured. For the most accurate readings, it is essential to have sufficient lengths of straight pipe before and after the flowmeter.

Compression fitting: This fitting securely inserts the flow sensor into the conduit and creates a leak-tight seal to prevent process gas from escaping.

Shoulder: Supports the sensor probe, ensuring it is precisely positioned at the correct depth and location within the conduit for accurate measurement.

Measuring mass flow with thermal mass flowmeters

Here's a breakdown of the process:

- Heat transfer: The velocity sensor is heated to a fixed temperature above the gas temperature.

- Cooling effect: As gas molecules flow past the sensor, they carry some heat away, cooling the sensor.

- Heat measurement: The electronics measure the energy needed to maintain the heated sensor at its target temperature.

- Mass flow calculation: The energy required to maintain the sensor temperature is directly proportional to the mass flow rate of the gas. The meter uses this information to calculate the flow rate precisely.

Applications of thermal mass flowmeters

These meters are used in many industrial and research applications, including:

- Flare gas monitoring: Measuring emissions for compliance, the ability to accurately measure changing gas compositions

- Compressed air audits: Uncovering waste and optimizing efficiency

- Natural gas distribution: Accurate billing and process control

- Wastewater treatment and biogas: Aeration flow optimization and renewable natural gas

- Semiconductor industry: Monitoring gas flows in fabrication processes

- Carbon dioxide: Chilling food and fermenting beverages

- Nitrogen and oxygen: Used in production plants

- Argon: Iron and steel-making

The importance of proper calibration

A flowmeter's accuracy depends entirely on its calibration. To ensure the best performance, thermal mass flowmeters must be calibrated using a closed-loop system that simulates the exact conditions of the real-world application.

This requires using the same gas, temperature and pressure settings that the meter will encounter in the field.

Industries where thermal mass flowmeters excel

Thermal mass flowmeters are used in a wide range of industries, including:

- Clean energy

- Natural gas distribution

- Flare gas

- Compressed air in manufacturing facilities

- Semiconductor manufacturing

- Wastewater treatment and biogas

- Natural gas to burners and boilers

- Carbon dioxide for chilling food and fermenting beverages

- Nitrogen and oxygen in production plants

- Argon for making iron and steel

Alternatives to thermal mass flowmeters

Other technologies for measuring flow rates include:

Coriolis mass flowmeters: These meters directly measure mass flow with high accuracy but can be more complex and expensive.

Velocity meters (vortex, turbine, ultrasonic): These meters measure fluid velocity, which must then be converted to mass flow rate, potentially introducing additional calculations and sources of inaccuracy.

Differential pressure flowmeters: DP meters measure the pressure difference across a restriction in the flow path. They are a mature technology but only offer limited turndown, can be affected by changes in fluid properties, and require complicated installation and maintenance. These meters must compensate for temperature and pressure to output mass flow and can introduce additional inaccuracies.

Positive displacement meters: These meters directly measure volumetric flow by repeatedly isolating and moving known fluid volumes. They are accurate but can be less suitable for large flows or applications with particles. These meters also must compensate for temperature and pressure to output mass flow, and this will cause a degradation in accuracy.

Thermal mass flow meters offer several advantages over these alternatives, including:

- Direct mass flow measurement: These meters directly measure mass flow, eliminating density or temperature compensations that might be needed for volumetric flowmeters.

- Wide measurement range: Capable of measuring both low and high flow rates.

- No moving parts: This design reduces wear, which requires less maintenance and makes the meter more reliable

- Versatility: Suited to various gasses and pipe sizes.

- Fast response time: Thermal mass flowmeters rapidly adapt to changes in flow conditions.