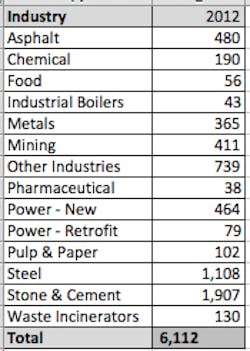

($ Millions)

Worldwide sales of fabric filter systems will be just under $6 billion in 2012, according to the latest forecast by the McIlvaine Company in its World Fabric Filter and Element Market report.

The stone and cement industry is expected to lead the way with purchases of nearly $2 billion, says McIlvaine. The utility industry will be a minor purchaser this year, but is expected to become a leading sector in 2013. ??New air toxic rules in the U.S. require coal-fired generators to meet low particulate emission levels. The U.S. EPA (epa.gov) predicts that up to 100 fabric filters will be needed to meet these regulations. The cost of the average fabric filter system when installed will be in excess of $40 million, according to McIlvaine. This $4 billion expenditure would be spread out over the 2013-2015 period.

China will be the biggest purchaser in part because of its very large cement industry, McIlvaine says. It is also the largest producer of steel.

In addition to the cost of systems, plants will spend $2.4 billion for replacement bags and cartridges. Bags are replaced every 3-5 years in most applications. Bags for high-temperature applications will cost up to 10 times as much as those for low-temperature service. McIlvaine also says membranes with non-woven substrates are gaining market share over conventional needle-felt composition.

For more information on the World Fabric Filter and Element Market report, click here.