In today’s process manufacturing environments, end users must choose from a multitude of widgets and innovations to help their plants run more smoothly. But what makes a new technology useful and not just another PowerPoint slide or webpage from a supplier detailing features and benefits?

When developing new process instrumentation applications for level and other measurements, it is often too easy to get excited about something new and innovative, while perhaps overlooking that investing in new technology for an industrial plant or facility environment is typically a much more rigorous process than upgrading to the latest version of a smartphone.

In this article, we will show how end users can evaluate and apply new products in their process manufacturing plants and facilities to deliver ongoing operational improvements.

Apps safely simplify troubleshooting

End users have many concerns with respect to their manufacturing processes, but most can be boiled down to safely and simply improving productivity. These needs are interconnected with each other and provide a solid basis for product selection and deployment.

For example, apps designed to run on smartphone and tablet mobile devices, such as the Endress+Hauser SmartBlue app for Android and iOS, can be used to monitor and verify calibration and status for level and other instruments, providing the functionality required for predictive maintenance to prevent downtime (Figure 1).

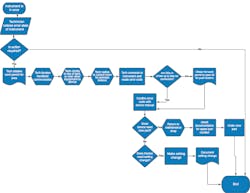

The flow chart in Figure 2 can be followed by a technician using hardwired connections to a level or other instrument, but it is safer and simpler to instead use an app because there is no need to open electrical panels or remove housing covers to access the instrument and connect for diagnostics, troubleshooting or commissioning.

By using the app’s Bluetooth connectivity to an instrument, technicians can access hard-to-reach devices up to 30 feet away, such as a level instrument mounted on the top of a tank. Visibility is clear on the mobile device even in low lighting, which is not always the case when trying to read an instrument’s nameplate, especially from a distance. This functionality eliminates the need for a manlift in certain cases, decreasing fall risks and job site accidents.

Bluetooth communications also eliminate the need for handheld communicators, which require their own maintenance, along with downtime for firmware and software updates. Replacing communicators with mobile devices cuts costs and allows technicians to work with familiar technology.

Commissioning made easier

The app’s commissioning wizards walk a technician through the startup from beginning to end and ensure no part is missed, which is especially important for safety integrity level (SIL) startup and verification because completing every step of SIL activation is essential for devices in safety systems to function as intended. For example, overfill protection is often provided by a level instrument rated for SIL service.

Combined with an onboard monitoring and verification functionality, such as Endress+Hauser’s Heartbeat technology, technicians can see process data and diagnostics in real time and with no measurement interruption. This allows them to perform predictive maintenance — decreasing the possibility of incidents due to equipment failure or product contamination — while improving productivity (Figure 3).

In a food and beverage processing plant, for example, this means not having to deal with ramifications due to quality issues from failed instrumentation. Product loss is not only a financial burden but can also be a safety concern for consumers, depending on the type of contamination and how much product makes it out the door before the issue is noticed. The effects of contamination can be far reaching, including product recalls and even consumer health issues in the worst case.

Onboard monitoring and verification reports, with information available both locally on a mobile device and remotely on a control and monitoring system, makes it much easier to implement preventative maintenance measures, improving both plant and consumer safety.

The ability to access reports, such as those generated by Endress+Hauser’s Heartbeat Verification and monitoring capabilities, also makes it much easier to create required documentation. Rather than manually filling out a report every time a setting is changed or an instrument is checked, end users can generate an “As Found” file before the change and an “As Left” file afterwards, eliminating any questions about who made the adjustment and enforcing homogeneity among technicians.

Saving steps and time

Imagine walking all the way across a plant to the shop, grabbing a communicator, walking back to the other side of the plant and then climbing up the side of a tank to access a level instrument — only to discover that the handheld you grabbed does not have the proper EDD or DTM file loaded to communicate with the instrument you are trying to troubleshoot. Wasted time and decreased personnel productivity from these types of issues can be significant, especially in plants spanning a wide area and requiring lots of time to traverse from one side to the other.

Once a technician has gone back and either updated the drivers or grabbed a different handheld with drivers preloaded, diagnostic information must be pulled from the device. Now that the diagnostic code has been retrieved, the technician will have to again return to the shop and look up the diagnostic information associated with the code. The technician will then have to make a decision about what to do with the level instrument, which could be difficult unless the manual for the instrument is at hand. If part replacement or a call to technical support is required, a return trip to the shop must be made.

Loading all this information into an app that is easily accessed and updated by technicians via a mobile device eliminates this back and forth between the level instrument’s location and the maintenance shop, creating a more productive and less frustrating work process. The ability to access all technical information, manuals and diagnostic codes through an app allows the technician to manage everything in a single trip to the instrument.

Heartbeat Verification and Heartbeat Monitoring provide homogenous report generation, allowing technicians to document issues without having to type information on a separate device, such as a laptop. Everything a technician needs is at their fingertips, quite literally. One single problem that may have lasted the entire workday now can be solved in a fraction of the time.

Conclusion

While the Endress+Hauser SmartBlue app and Heartbeat Verification were used to illustrate these examples for level instrumentation, the guidelines for safely and simply improving productivity can be used as a standard for selecting and implementing any new instrument or innovation. If a new product can meet this standard, it should be considered, and if it does not it may be just an area to watch for further developments, but not yet ready for prime time.

Purchasing and installing the coolest widget or tool on the market only makes sense if it provides intrinsic value in the manufacturing process. Investment in new products requires a specific need to be met, along with justification for changing standard operating procedures that may have been in place for decades. Before this step is taken, end users must first make sure a pressing problem will be solved safely and simply — and only proceeding if that is the case.

Ashley David is a product marketing manager for Endress+Hauser. She is currently focused on providing strategic vision, leadership and marketing direction of Endress+Hauser level + pressure products, as well as leading and managing the development of business portfolio launch concepts and business marketing plans. Previously, David has served as a regional business driver specializing in pressure, temperature and system products for Endress+Hauser. She also spent time working in technical support and application engineering, creating expertise in customer processes and manufacturing.

About the Author

Ashley David

Product marketing manager for Endress+Hauser

Ashley David is a product marketing manager for Endress+Hauser. She is currently focused on providing strategic vision, leadership and marketing direction of Endress+Hauser level + pressure products, as well as leading and managing the development of business portfolio launch concepts and business marketing plans. Previously, David has served as a regional business driver specializing in pressure, temperature and system products for Endress+Hauser. She also spent time working in technical support and application engineering, creating expertise in customer processes and manufacturing.