Understanding and employing the benefits of instrumentation diagnostics

Just as consumer electronics have advanced over the past few decades, improvements in industrial technologies have been just as dramatic. The capabilities of a flowmeter or pressure transmitter of today are light years ahead of what was possible in 1975 or even 1995, and areas of improvement often relate to diagnostics in many forms.

Instrument diagnostics grew out of the development of transmitter electronics necessary to linearize, range and convert raw analog data into engineering units, and to standardized data transmission formats (e.g., 4-20 mA current loops). As the analysis capabilities of transmitter electronics grew in sophistication, adding diagnostic capabilities was the next development step.

This is the first in a series of five articles where Emerson will examine the role of instrumentation diagnostics for process manufacturers. To start, here is an overview of what diagnostic capabilities are now available, and how plant personnel use them to improve operations.

Device diagnostics

The first widely used diagnostic capabilities analyzed the health of the instrument itself and were characterized as device diagnostics. If an internal component was behaving erratically or had failed entirely, the transmitter would send a message via HART (Figure 1), Foundation Fieldbus or some other digital protocol to warn the reliability team of a developing problem or outage.

This capability became the basis for many reliability and maintenance management programs. Technicians were able to identify and deal with a problem before a full outage might interrupt a plant’s production. Over the years, device diagnostics have become more sophisticated, extending the range of capabilities, but also improving the interface between the software and users.

A key example is Emerson’s Smart Meter Verification, providing deep device diagnostic information from Coriolis, magnetic and ultrasonic flowmeters. The flow transmitter uses on-board diagnostics to monitor key performance indicators continuously. This maintains measurement accuracy and meter integrity, reducing maintenance and calibration costs through early detection of issues.

As a case-in-point, a wastewater treatment plant in the western U.S. added Smart Meter Verification to its fleet of Rosemount 8750W magnetic flowmeters. Using data provided by the upgraded transmitters, the frequency of flowmeter calibration was reduced from four times each year to fewer than once each year.

Process diagnostics

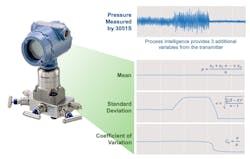

Today’s sophisticated instruments can often provide insight into the process itself since an operating process unit exhibits specific characteristics that can be detected and characterized by the transmitters. For example, a differential pressure (DP) transmitter takes readings so rapidly (Figure 2) that it can recognize fluctuation patterns as process noise, much like an actual acoustic sensor. When these patterns change and there has been no direct cause related to the process, something may be amiss, such as impulse line clogging.

If the change crosses a designated threshold, the transmitter can warn operators and maintenance engineers that it may require some attention. The process noise just mentioned can indicate more than just line clogging as it can point to a variety of sources, including:

- Pump and valve cavitation

- Distillation column flooding

- Air entrained in a liquid stream

- Furnace flame instability

- Process leakage

- Agitation loss

Any of these issues can reduce process efficiency, contribute to equipment wear and breakdown, or presage failure. Discovering when a new problem is developing and locating the source can be a difficult process if the only tools are manual and depend on a skilled technician being in the right place at the right time, but process diagnostics address this issue effectively.

For example, a major chemical company needed to monitor steam traps. Rosemount 708 Wireless Acoustic Transmitters were installed to listen for acoustic signatures and monitor temperature, both vital signs related to steam trap operation. The steam trap monitors took only two days to install, and the payback was just six weeks through detection and remediation of previously unknown losses.

Installation and maintenance diagnostics

Installing a new instrument in a working process can be complex and must be handled very carefully to ensure everything operates as desired. Installation and maintenance diagnostics are still critical long after a new instrument has been running correctly for years.

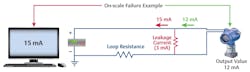

For example, a perfectly performing instrument depends on its 4-20 mA connection to the automation host system to deliver correct readings. While current loops are very robust, there are potential pitfalls that can result in on-scale failures capable of sending inaccurate readings to the host system and operators.

Leakage current — Some situations can create a partial short circuit (Figure 3) where an additional circuit path is formed without disrupting the signal entirely.

Increased electrical load — If the loop’s power supply is unstable and cannot maintain adequate voltage, or if terminals are corroded or loose, the transmitter cannot deliver enough current. If voltage moves outside of a defined threshold, the transmitter will generate an alarm or alert.

As a case-in-point, a petrochemical producer was dealing with a very hot environment around its de-hydro unit. Erratic behavior of a strategic Rosemount 3051S Pressure Transmitter left technicians believing cabling was melting in the conduit. Loop integrity diagnostics indicated that the actual problem was mis-configured jumpers in the automation system. Early detection of this issue avoided major expense and rewiring.

Confidence diagnostic

While there is no specific user confidence indicator, it is important for technicians to know they have done their work correctly and a given instrument is working exactly as planned. Multiple diagnostics, working together, can verify that everything is indeed correct.

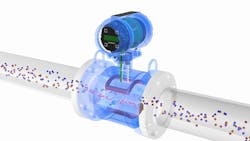

Naturally, the type of instrument determines which types of diagnostics are the most important and indicative of success. Fortunately, the range of diagnostics from Emerson’s instrumentation offerings are broad enough to cover all types. For example, a magnetic flowmeter can provide five diagnostics to verify confidence in its correct operation:

- Smart Meter Verification — This is a compilation of multiple variables indicating operational integrity (Figure 4).

- Grounding and wiring fault — This covers many aspects to verify correct terminations.

- High process noise — The new flowmeter should indicate noise levels similar to existing nearby instruments.

- Coated electrodes — A new flowmeter should not indicate coated electrodes.

- Empty pipe — Once the process is running again, it should be possible to verify independently whether flow has been established, and the flowmeter should agree.

When these are all taken together, it should be clear that the instrument is working correctly.

Response diagnostics

In some cases, a process or an item of equipment will malfunction and create a problem to which maintenance or reliability team members must respond. In such situations, instrument diagnostics are a major troubleshooting tool.

Say a single pressure reading is out of line with what it should be and there is no attributable cause. It reads consistently high and does not reach the low end of its normal range. How do diagnostics help troubleshoot?

- Basic device diagnostics show no internal transmitter malfunction.

- Plugged impulse line diagnostics indicate the line is open.

- Comparing the local instrument pressure reading against the indicator in the control room shows a difference of 12%.

- Loop integrity analysis shows a connection problem between the instrument and I/O terminal at the DCS, pinpointing the problem.

So, what happened? A technician working in a marshalling cabinet likely disturbed old terminations causing leakage current on the line. Diagnostic data makes these types of situations easier to diagnose.

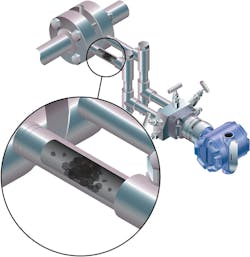

As a case-in-point, a petrochemical processor had problems with particles from a batch reactor getting into the output stream and disrupting the flow measurement. Using data from a Rosemount magnetic flowmeter (Figure 5), it became an easy task to detect the particles based on the characteristic process noise they created. The transmitter was able to effectively cancel this noise, resulting in an accurate flow reading under all conditions.

Prevention diagnostics

The original concept of using diagnostics to drive predictive maintenance is just as relevant today as it was 30 years ago. Where strategic instruments are necessary to control processes, the loss of a flowmeter or temperature sensor can cause a costly unscheduled shutdown or a safety incident. Preventive diagnostics also eliminate the costly and wasteful practice of performing maintenance by a schedule, often resulting in repair or replacement of instruments that are functioning perfectly well.

These preventive capabilities are not limited to just the device diagnostics, as important as those capabilities are. For example, the ability of a pressure transmitter to detect cavitation can avoid pump damage, or detection of solids in a liquid flow via a plugged impulse line diagnostic (Figure 6) can warn of a break-through in a catalyst bed. The ultimate value of prevention diagnostics is to avoid upsets and downtime, while providing data necessary to make expert-level decisions before emergencies occur.

As a case-in-point, a large petrochemical plant had more than 100 flowmeters working in custody transfer applications, calling for verification at least twice per year, often requiring removal for calibration. Using Smart Meter Verification with Micro Motion Coriolis flow meters, full verification was possible in-situ with no performance degradation, saving $800,000 per year.

Doing more with less

As we move farther into the future, it is safe to say that processing facilities are becoming more complex and tightly regulated, while the number of staff overseeing the operation is declining, so automation is necessary to make up the difference. Front-line teams, including maintenance and instrumentation technicians backed by operators and process engineers, find their day-to-day responsibilities more demanding. The only way to keep up is by using new technologies able to perform repetitive tasks. Diagnostic capabilities of today’s instrumentation provide this capability to bridge these operational gaps.

There will be four more articles in this series, examining the individual areas introduced above in greater depth, including:

- Device diagnostics

- Process diagnostics

- Installation and maintenance diagnostics

- End-user solutions

Each article will help process manufacturers understand and implement these solutions to enhance overall operations, supporting their front-line teams by directing their efforts towards the highest value-added tasks.

Kelly Albano has been with Emerson for over 12 years and is a product manager for Emerson Coriolis transmitters and software. She is focused on improving user experiences and guiding users through digital transformations. Albano holds an undergraduate degree in Environmental Engineering from University of Colorado at Boulder, and an MBA with a Marketing Management Certificate from Colorado State University.

About the Author

Kelly Albano

Product manager for Emerson Coriolis transmitters and software at Emerson

Kelly Albano has been with Emerson for over 12 years and is a product manager for Emerson Coriolis transmitters and software. She is focused on improving user experiences and guiding users through digital transformations. Albano holds an undergraduate degree in Environmental Engineering from University of Colorado at Boulder, and an MBA with a Marketing Management Certificate from Colorado State University.