The importance of accurate flow measurement in industrial processes

The ability to accurately understand, control and monitor industrial processes is pivotal to the successful, commercially viable operation of plants and processes in every industrial sector. Despite this, instrumentation and flow measurement are not always given the level of resource and investment that they deserve, and measurement in general is not always well understood.

Industrial flow measurement systems

Many factors can affect the performance of a measurement system. Some of these are common to almost any flow measurement system, such as the correct installation of the instrument with appropriate flow conditioning; calibration, which is suitable for the operating environment of the meter; appropriate secondary instrumentation; and fluid properties characterization. However, there can also be a number of factors that are highly application-specific, such as the presence of contamination or additional phases within the flow; contaminants or solid particulates that cause mechanical wear, erosion, deposition or corrosion; or any number of challenging operating environments that can adversely affect measurement performance.

Factors that adversely affect or undermine measurement performance are often particularly poorly understood or ignored entirely. However, this can be a mistake, as the relatively little work required to develop and maintain effective measurement systems can reap substantial benefits.

Figure 1. Traceability pyramid. Courtesy of TUV SUD NEL

When operating a process that relies on measurement systems for the purposes of process control, monitoring or safety, the ability to characterize the accuracy of the measurement system is a critical means of providing confidence in its performance. This requires an understanding of measurement uncertainty, traceability and calibration, as well as a management system that incorporates a measurement policy or philosophy and a maintenance schedule.

Consider the pharmaceuticals industry, for example, where complex multistage chemical processes are required to produce lifesaving products for medical applications. Flowmeters are used to control the mixing of quantities at critical stages as well as the sizing, coloring and coating of pills, to name a few applications. Turbine, ultrasonic and Coriolis flowmeters are all popular options; however, precise timing and accuracy are critical to ensure repeatable, high-quality output. In these applications, quality control is literally a matter of life or death. Understanding the accuracy of key measurements is critical to ensuring consistent product quality.

Another example of the importance of accurate measurement can be found in the food and beverage industry. In most countries, manufacture and sale of alcoholic beverages must be recorded for legal and taxation purposes. Such measurements are essentially similar to the custody transfer measurements undertaken in the oil and gas industry. Given the quantity of beer, wine and spirits sold across the globe, this represents enormous taxation revenue for alcohol-producing nations. According to the BBC, the U.K. exported 1.2 billion bottles of Scotch whisky in 2017. This equated to approximately £4.36 billion in sales. A measurement uncertainty of 0.5 percent on volume across the industry would result in a financial exposure of around £21.8 million. This is obviously a highly simplistic example, but it illustrates the potential impact of mismeasurement. There are endless applications across all industrial sectors where flow measurement has a similarly critical role to play.

To achieve the accuracy that is so critical to trade and commerce, most countries have a dedicated regulatory framework that supports national measurement infrastructure designed to facilitate and regulate good measurement practice. In the U.K., this system is officially known as the National Measurement System (NMS), which is delivered through the U.K.’s Department for Business, Energy & Industrial Strategy (BEIS). To support and develop a national measurement infrastructure in the U.K., BEIS allocates £65 million funding.

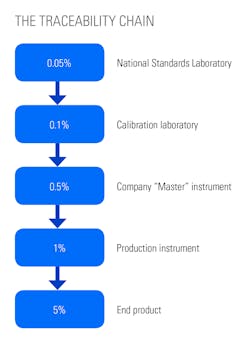

A fundamental feature to accurate measurement is traceability. Traceability plays a vital role in national measurement infrastructure; without it, accurate measurement and confidence in a measurement system is impossible to achieve.

Traceability requires that it must be possible to trace a measurement device, normally through calibration, back to the national standard. Without this, it is impossible to effectively characterize the uncertainty of a given measurement system.

As we move up the traceability chain toward a given measurement standard, the uncertainty in measurement is reduced; however, to achieve low uncertainty, it is usually necessary to invest more money in the system in terms of increased capital and maintenance costs. This is important to consider, as the most accurate system is not always the correct solution for a given application. Owing to the cost penalty associated with achieving and maintaining low uncertainty, the requirements for a given application need to be considered prior to system design and component selection.

Figure 2. Traceability chain. Courtesy of TUV SUD NEL

Despite the work invested in maintaining and regulating the NMS, it is occasionally found — when visiting or auditing plants and factories — that instruments are not installed or operated in accordance with the appropriate standard or, in some instances, no longer traceable to the appropriate standard. Furthermore, it is not uncommon to find flowmeters in service where the operator has no record of when the device was calibrated and no planned maintenance for the system.

A common finding when visiting plants and production environments is that they are often not taking full advantage of the available technology. In recent years, measurement technology has advanced substantially — principally owing to the development of advanced electronics and diagnostics, wireless communications and powerful data processing. This can present the ability to monitor system health and provide insight into a process and its performance. It can be an extremely powerful tool in the continual drive for improvement and process optimization. In many cases, this has left legacy measurement systems behind; however, occasionally, it has been found that the technology is already in place but not fully exploited.

Application example: Spirits bottling plant

The following is an example from a spirits bottling plant that highlights such a situation. During tanker offloading operations, it was observed that the plant had purchased an advanced (and expensive) Coriolis flowmeter as a means to meter incoming product. Meanwhile in the control room, a small team was taking manual samples and using hydrometers to measure the density, which were written on paper and then typed into a spreadsheet as a means of evaluating the ABV (alcohol by volume) of the incoming product. One of the advantages of Coriolis flowmeters is that they directly measure both mass flow rate and fluid density at the same time. When asked why they didn’t use the density output from the Coriolis flowmeter to continuously measure the ABV of the incoming product, they were unaware that Coriolis meters had this capability. Whether this replaces archaic processes or simply augments them with modern and robust techniques, this is a powerful and potentially valuable capability that is underutilized.

So why don’t companies invest more in such powerful diagnostic tools? A key factor is the apparent lack of impact occurring from high measurement uncertainty. If we consider the oil and gas and petrochemical industries, the story is usually very different. These organizations typically have dedicated metering departments. The reason for this is that hydrocarbon-based products are high value, thus there is a direct fiscal impact in the uncertainty associated with their flow measurements. When looking at hydrocarbon systems, it is easy to see how small uncertainties can lead to large financial exposure — even over short timescales.

Another key factor is that these industries are regulated much more tightly than other industries due to the fiscal value of the metered product. The same degree of stringent regulation does not often apply to flow measurements in the context of industrial or plant environments compared to the oil and gas sector, and companies within the food and beverage, power and chemical industries will rarely undertake full flow measurement audits.

In some industries, there is a degree of inertia regarding the adoption of new processes or technology and often understandably so. Many processes that have been in operation for years — and even ones that already incorporate flow measurement — work fine as they are, so there’s no need to fix them. Nevertheless, instrumentation is often underutilized.

“Given the sophistication and capability of modern flow measurement technology, such systems can do far more than simply measure flow rate; they can also provide powerful diagnostic capability that can yield insight into both the performance of the measurement system and the process in which it operates.”

Regardless of the industry, a key question is, do you have an understanding of the uncertainty that you require for your application and the uncertainty of the given measurement system? Furthermore, how does your measurement system perform over time, how frequently do you calibrate, and do you have any past performance data that would allow you to evaluate the optimal calibration period? Fundamentally, are these factored into your quality system?

Conclusion

Traceability and good measurement practice are critical to achieving accurate, repeatable flow measurement. However, selecting the appropriate solution is contingent upon understanding the uncertainty and performance required for a given application, which requires a fundamental understanding of metrology as well as the process to which it is applied. Getting this right has the potential to yield substantial commercial benefits through enhanced efficiency and control. Furthermore, given the sophistication and capability of modern flow measurement technology, such systems can do far more than simply measure flow rate; they can also provide powerful diagnostic capability that can yield insight into both the performance of the measurement system and the process in which it operates.

Neil Bowman is a Chartered Mechanical Engineer, providing fluid mechanics and flow measurement consultancy services to a range of industry sectors. He frequently delivers NEL’s Principles and Practice Flow Measurement course and has experience with a range of flow measurement technologies, both from a theoretical and practical perspective, and in challenging and nonstandard applications. He is a project engineer at TÜV SÜD NEL, a global centre of excellence for flow measurement and fluid flow systems and the U.K.’s National Measurement Institute for Flow Measurement. TÜV SÜD NEL is part of the TÜV SÜD Group.