Flowmeter piping requirements

When a fluid flowing through a pipe assumes a desirable flow profile, it moves uniformly with the greatest velocities near the center of the pipe. Improper flowmeter installation can disturb this profile and degrade measurement accuracy. Flow-profile distortion and swirl — the two most prominent types of fluid disturbance that affect a meter’s flow coefficients — are typically the products of improper piping configuration.

Fluid profile distortion occurs when an obstruction — such as a partially open valve or a poorly mounted flange gasket — partially blocks the pipe. Swirl occurs when the fluid moves through piping bends in different planes. Swirl is far more difficult to correct than flow-profile distortion. Obstructions upstream and near the flowmeter can cause errors ranging beyond 50 percent.

Flowmeter manufacturers will recommend various lengths of straight pipe upstream and downstream of the flowmeter to attain a fully developed desirable flow profile. Long straight-pipe lengths can be avoided through the use of flow-straightening devices and flow conditioners. Flow-straightening devices include tube bundles, perforated plates, and internal tabs. These solutions reduce swirl, but not flow profile variations; some may even introduce a distorted profile. Flow conditioners can reduce swirl and also mimic a fully developed profile. A grated plate, for example, can introduce such a profile.

Differential-pressure flowmeter piping requirements

DP flowmeters measure the drop in pressure across a flow element in the piping, such as an orifice plate. The measured flowrate is a function of the pressure drop. So the flowmeter consists of the flow element in the piping, as well as a nearby differential-pressure meter. Small tubes, called impulse lines, on either side of the flow element lead to the DP meter for measurement.

Professional organizations, such as ISA, ANSI, API, ASME, and AGA, offer installation guidelines for DP flowmeter installations. These guidelines help to minimize disturbances to the fluid-velocity profile. Often, for example, measurements of temperature and static pressure are desirable in addition to flowrate. To minimize flow disturbances from an added pressure sensor, install a tee for connection to the appropriate DP impulse line. Similarly, install a thermowell used for temperature measurement at least 10 pipe diameters downstream of the flow element. Such installations should be characterized by smoothly ground welds and trimmed gaskets to eliminate protrusions into the fluid stream.

Straight-pipe runs upstream and downstream from the DP flow element help to guarantee a fully developed fluid-velocity profile that permits a predictable pressure drop. For an orifice, the length of straight run required depends on both the beta ratio of the installation and on the nature of the upstream components in the pipeline. (Beta ratio is the diameter of the orifice divided by the pipe diameter.) For example, when a single 90-degree elbow precedes an orifice plate, the straight-pipe requirement ranges from six to 20 pipe diameters as the beta ratio increases from 0.2 to 0.8.

The size and orientation of the impulse-line pressure taps depend on both the pipe size and the process fluid. The recommended maximum diameters of pressure-tap holes through the pipe or flange are:

- ¼ inch for pipes under two inches in diameter;

- 3⁄8 inch for two- and three-inch diameter pipes;

- ½ for four- to eight-inch diameter pipes; and

- ¾ inch for pipes larger than eight inches in diameter.

Size both pressure taps and leads with the same diameter. Where the hole breaks through the inside pipe surface, make sure it is flush with the inside pipe surface with no roughness, burrs, or wire edges. Connections to pressure taps should be made by nipples, couplings, or adaptors welded to the outside surface of the pipe.

On services where the process fluid can plug the pressure taps or might gel or freeze in the impulse lines, consider chemical seals. Connection sizes are usually larger in these cases. When using chemical seals, assure that the two connecting capillaries that route to the DP meter experience the same temperature and keep them both shielded from sunlight.

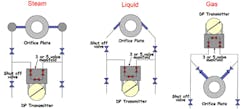

Locate the DP transmitter as close to the primary element as possible with short lead lines of the same diameter. Figure 1 shows recommended configurations for various DP applications. In steam service, the horizontal lead lines should be kept as short as possible, and they should be tilted (with a minimum gradient of one in/ft with respect to the piping) towards the tap, so that condensate can drain back into the pipe. In clean liquid or gas service, purge the lead lines through the DP cell vent or drain connections. Flush them for several minutes to remove all air, because entrapped air can offset zero calibration.

If the process temperature exceeds the maximum temperature limitation of the DP meter, either use chemical seals or make the lead lines long enough to cool the fluid. If more cooling is necessary, install a coiled section of tubing (pigtail) in the lead lines.

The frequency of inspection or replacement of a primary element depends on the process fluid’s erosive and corrosive properties, as well as the overall accuracy required. If no previous experience exists, remove the orifice plate for inspection during the first three, six, and 12 months of its operation. Based on visual inspection of the plate, develop a reasonable maintenance cycle from the findings. Keep orifices used for material balance calculations on the same maintenance cycle.

Magnetic flowmeter piping requirements

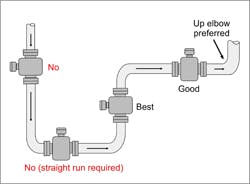

Always pipe an electromagnetic flowmeter (magmeter) so it is full of liquid. The pipe configuration should avoid a buildup or accumulation of any secondary phase (solids or air). Any entrained air should be carried out of the meter by flow, or by buoyancy (at zero flow). Likewise, any solids should fall from the meter by gravity under zero flow. You can install magmeters in horizontal lines, but best practice calls for installation in vertical lines with upwards flow (Figure 2).

Pipe the magmeter to remain full at zero flow. Otherwise the output can become erratic because of electrode exposure to air. If draining at zero flow is inevitable, use empty pipe detection options to prevent erratic output.

Magmeters are relatively insensitive to errors caused by nonsymmetrical velocity patterns or swirl. The general rule of thumb for straight piping is a five-diameter length of piping upstream and three diameters downstream from the meter (measured from the center of the tube). Independent testing has shown that magmeters may be affected by piping effects when the length of upstream straight pipe is less than three pipe diameters. Errors from piping effects generally run between 0.1 percent and 1.5 percent, depending on the exact configuration of piping and length of pipe run upstream of the meter.

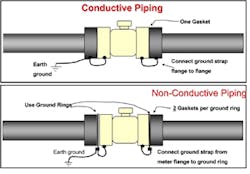

The magnetic field across the electrodes is very small, making the magmeter susceptible to stray ground currents in the pipeline. If the pipeline is made of nonconducting materials, such as plastic, or is lined with an insulating material, these stray ground potentials can cause significant measuring errors. Five or six millivolts of stray potential in the measuring section of the flowmeter can render the signal meaningless. The transmitter will confuse this stray potential with the actual signal and provide inaccurate flow readings.

If the pipeline is made of an unlined conducting material, the process ground should be excellent, and no further measures are normally required. As a precaution, install grounding straps between the pipe flanges and magmeter flanges, and connect one pipe flange to a good ground, as shown in Figure 3.

If the connecting pipe is not electrically conducting or is lined with insulating material, use grounding rings, disks, or electrodes. Strap the grounding disks or rings to the detector head flanges at either end. If the magmeter contains grounding electrodes, the manufacturer will connect them to ground inside the magmeter casing.

Insertion magnetic flowmeter piping requirements

Insertion magmeter probes offer an economical alternative to full-bore meters or a verification device to check the performance of an existing meter. Correctly applied, these sensors provide reliable, maintenance-free operation with good accuracy in many difficult applications and industries. Insertion magmeters suit both temporary and permanent applications in pipes up to 320-inches diameter. Hot-tap capabilities through a valve allow installation while the pipe is under full working conditions.

Preferably, the probe’s end will reach the centerline of the pipe following installation. But if the probe will experience exceptionally high flow velocities at the pipe’s center, raise it to a point in the pipe representing the flow’s mean velocity. This point is generally 1⁄8" of the pipe diameter. Manufacturers provide tables indicating the maximum flow velocity for various insertion lengths.

For optimum operation, the pipe conditions upstream from the insertion magmeter must be good. ISO 7145, for example, calls for 25 to 50 diameters of straight pipe upstream from the insertion meter. If these lengths are not possible, instrument engineers must determine the flow profile to provide good insertion magmeter accuracies.

Vortex flowmeter piping requirements

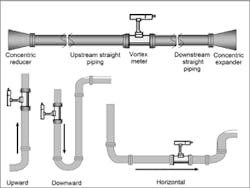

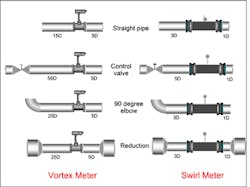

Sizing a vortex meter by the piping line size is poor practice. The line-size vortex meter may not work at all. If the range of flowrates is unknown, first make some approximate measurements (using portable pitot or clamp-on ultrasonic devices). About half of all vortex meter installations require the "necking down" of oversized process piping by concentric reducers and expanders (Figure 4). Even with flow straightening devices installed, the installation will require some straight (relaxation) piping.

The vortex meter requires a well-developed and symmetrical flow velocity profile, free from any distortions or swirls. This necessitates the use of relatively long straight piping upstream and downstream from the meter to condition the flow. Swirl meters, which are similar to vortex meters, contain flow-straightening elements, thus requiring less straight pipe.

The straight length of pipe for the vortex meter must be the same size as the meter and its length should be about the same as required for an orifice installation with a beta ratio of 0.7. Most vortex flowmeter manufacturers recommend a minimum length of 30 pipe diameters downstream of control valves, and three-to-four pipe diameters between the meter and downstream pressure taps. Temperature elements should be small and located five-to-six pipe-diameter lengths downstream.

Vortex meters can be installed vertically, horizontally, or at any angle, as long as the pipe is kept full. Installing the meter in a vertical line with upward flow will always keep the pipe full. When the flow is horizontal or downward in a vertical line, keep the downstream piping elevated to trap the fluid. Use check valves to keep the piping full of liquid in the no-flow condition. If the replacement of the meter in a particular piping configuration requires stopping the flow, block and bypass valves can be installed around the meter.

Mating flanges (on Schedule 40 or Schedule 80 mating piping) must have the same diameter and smooth bore as the vortex flowmeter. Use weld-neck flanges rather than reducing flanges. Make sure the inner surface of the mating pipe is free from mill scale, pits, holes, reaming scores, and bumps for a distance of four pipe diameters upstream and two pipe diameters downstream of the meter. The bores of the meter, gaskets, and adjacent piping must be carefully aligned to eliminate any obstructions or steps.

You can avoid excessive pipe vibration by supporting the piping on both sides of the meter, or by rotating the meter so that the sensor is moved out of the plane of the vibration. Process noise due to valve chattering, steam traps, or pumps can result in high readings or nonzero readings under no-flow conditions. Most meter electronics allow for increasing the noise filter settings, but increased noise reduction usually also decreases the low-flow sensitivity of the meter. One option is to relocate the meter to a less noisy part of the process.

Coriolis flowmeter piping requirements

Coriolis flowmeters measure mass flow directly and offer few installation limitations. These flowmeters are insensitive to velocity profile distortion and swirl. This characteristic avoids the necessity of straight runs of relaxation piping upstream and downstream of the meter to condition the flow. Additionally, Coriolis flowmeters handle all fluids regardless of their Reynolds number.

Install Coriolis flowmeters so they remain full of liquid and so air cannot get trapped inside the tubes. In sanitary installations, make sure the meter drains completely. The most desirable installation is in vertical pipes with upward flow, but installation in horizontal piping is also acceptable. Installations where the fluid flows downward in a vertical pipe are not recommended. Good practice calls for upstream installation of strainers, filters, or air/vapor eliminators as necessary to remove all undesirable secondary phases and air bubbles. Install control valves downstream from Coriolis meters to increase backpressure on them and to decrease the probability of cavitation or flashing.

Deposits and strong vibration can degrade accuracy. Newer Coriolis flowmeter designs, however, resist normal pipe vibration if the surrounding process piping properly supports the meter. No special supports or pads are needed for the flow tube. If the installation instructions require special hardware or supports, the meter design is likely to be sensitive to vibration.

Turbine flowmeter piping requirements

Typical manufacturer specifications for turbine meters call for straight-pipe lengths of 10-15 pipe diameters upstream and five diameters downstream. Additional straight-pipe recommendations include:

- 20 pipe diameters for 90-degree elbow, tee, filter, strainer, or thermowell;

- 25 pipe diameters for a partially open valve; and

- 50 pipe diameters for two elbows in different planes or if the flow is spiraling.

Typically, turbine meters require the installation of straightening vanes and flushing strainers or filters upstream of the meter. Straightening vanes can reduce the lengths of straight pipe otherwise required. Strainers and filters eliminate solids entrained in the fluid that can otherwise damage the turbine rotor.

Because valves installed in the piping can cause significant errors, use full-bore shutoff valves that are fully open during meter operation. Install control valves only on the downstream side of the meter.

A sudden pressure drop upstream can result in flashing or cavitations within the turbine meter. Flashing causes the meter to read high, while cavitations result in rotor damage.

Downstream pressure must equal 1.25 times the vapor pressure plus twice the pressure drop. Small amounts of air entrainment (<100 mg/l) will also make the meter read high, while large quantities of air can destroy the rotor. For a sudden drop in flowrate, the turbine meter may read high because of the stored inertia in the rotor.

Ultrasonic flowmeter piping requirements

Ultrasonic flowmeters come in two basic types—Doppler and transit time. Doppler flowmeters measure a frequency shift from beam reflections off bubbles or particles in a fluid. Transit-time flowmeters measure the time difference between ultrasonic beams moving with and against the flow. Clean fluid applications will generally rule out Doppler flowmeters. Transit-time meters work well with clean and viscous liquids.

Flowmeters having multiple ultrasonic beams are less affected by flow profile disturbances than single-beam meters. Excess solids or fluids with entrained gases may block the ultrasonic pulses in transit-time meters. Raw wastewater applications, for example, usually have too few acoustic discontinuities for Doppler and are not clean enough for transit-time measurements.

Most recommendations call for fluid Reynolds numbers less than 4,000 (laminar flow) or above 10,000 (turbulent flow). Nonlinearities in the transition region between these two Reynolds numbers degrade meter accuracies.

Ultrasonic flowmeters are not applicable to slurries that are acoustically absorbent, such as lime or kaolin slurries. Highly absorbent solids attenuate the signal below usable strength.

The ultrasonic flowmeters should be installed upstream of flow obstacles, such as elbows, reducers, or valves. Ensure that the longest possible straight pipe is between the obstacle and the meter. The length of straight pipe can be reduced to five pipe diameters if an additional error of 1 percent maximum is acceptable.

Paying attention to these recommendations for flowmeter installations will help ensure successful applications with good accuracies.

This is the second article in a five-part series on the history and operation of flowmeter technology. Part III will appear in the June issue.

Greg Livelli is a senior product manager for ABB Instrumentation, based in Warminster, Pa. He has more than 15 years experience in the design and marketing of flowmetering equipment. Mr. Livelli earned an MBA from Regis University and a bachelor’s degree in Mechanical Engineering from New Jersey Institute of Technology. Mr. Livelli can be reached at [email protected] or 215-674-6641.