Photo courtesy of Apple

The following technologies represent the final nominees for the 2011 Flow Control Innovation Awards program. Nominees include novel technology solutions for fluid handling applications in the categories of fluid measurement, control and containment. Please review the technology summaries provided below, and visit our Facebook polling page to vote for the technology you believe is the most innovative among this year”s nominees. All voters will be entered into a random drawing to win an Apple iPhone 4G. Innovation Awards winners will be announced in the September issue of Flow Control, with extended case studies/application stories on each of the winning technologies featured in the October issue. If you have questions and/or require additional information on any of the technologies highlighted below, please contact Matt Migliore at 610.828.1711 or [email protected]. Thanks for supporting the Flow Control Innovation Awards program.

VOTING IS NOW CLOSED. Thank you for supporting the Flow Control Innovation Awards program this year. 2011 winners will be announced in the September issue of Flow Control Magazine.

NOMINEES: |Measurement| Cameron | COX Flow Measurement | Emerson Process Management – Micro Motion | Endress+Hauser | Fluid Components International | Flow Line Options Corp | Greyline Instruments | INKnet Systems | Innovative Sensor Technologies | LJ Star | McCrometer | Sage Metering | Siargo | Spirax Sarco | Veris |Control| Almatec | Brooks Instrument | Burkert | Emerson Process Management – Fisher | Hawk Measurement | seepex | Sierra Instruments | Top Line Process Equipment Company | Warren Rupp |Containment| Colder Products | Kuriyama of America | Trelleborg Sealing Solutions

MEASUREMENTDifferential Pressure-Based Multi-Fluid Meter

The NuFlo Cone meter features a hydrodynamic design for easy installation and no moving parts. The design enables a cleaning (or sweeping) effect from the velocity increase in the throat and around the differential producer. The cone meter’s easy installation and compact size is an advantage when used in an offshore platform process, reducing costs and installation time. In addition, the meter is manufactured in a facility that is ISP 9001, API 22.2-certified, and GOST-approved for natural gas custody transfer in the Russian Federation.

To vote for this technology, click here. | To return to the list of nominees, click here.

Aluminum construction creates rotor-blade sensing issues, which are overcome by the use of a high-sensitivity amplifier with coupling and processing characteristics. Plus, the meter’s smaller packaging, lighter weight, and embedded pickoff coils work well in small areas subject to high vibrations. Combine this with extended-life ceramic bearings and precision primary standard calibrations, and the meter provides top performance for competitive and critical measurement applications.

The ALDR design utilizes a 100-ohm RTD to measure fluid temperatures and correct for fluid viscosity variances. The flow computer takes full advantage of the capability and provides a corrected flow output, which is enhanced by the dual rotors’ ability to extend the UVC usable flow measurement range. Embedded pickoff coils withstand vibration typically found in the automotive and aerospace industries by reducing mass and size. This design does not employ flow straighteners since the dual-rotor cancels out fluid swirl effects, delivering a flowmeter package that will fit in limited-space scenarios.

To vote for this technology, click here. | To return to the list of nominees, click here.

Mass Transmitter for High-Speed, High-Accuracy DosingWith increasing pressure on production quality efficiency and throughput, traditional volumetric- and meter-based technologies are no longer sufficient. Micro Motion filling meters deliver mass, density and temperature process data in one device, supporting continuous monitoring of product quality with a complete real-time view of fluid characteristics. Digital communications provide continuous monitoring of density and temperature for real-time quality control, and enable “on the fly” changes to fill target or recipe.

The transmitter’s Automatic Overshoot Compensation (AOC) feature automatically adjusts valve management to compensate for changes in process conditions to deliver accuracy and reliability with minimal setup and maintenance. With direct mass measurement and superior stability (turndown), the Filling Mass Transmitter is suitable for filling a variety of container sizes and products with a single sensor.

To vote for this technology, click here. | To return to the list of nominees, click here.

Coriolis mass flow technology has historically been contained to traditional four-wire power/signal methodologies due to the need to power the sensor, amplifier, transmitter, and outputs. The Promass E 200 is innovative in that it maintains the highest levels of Coriolis accuracy and reliability while operating under a two-wire, loop-powered concept, which significantly limits the available power to the Coriolis meter.

In addition to the Adaptive Power Techniques used by the Promass E 200, this product line has set a standard for commonality across the Endress+Hauser flow and level product lines. The two-wire product lines from E+H will now share common Human Machine Interface, spare parts, and electronics modules. The new HistoROM capability provides an onboard nonvolatile device memory that enables data management and automatic data backup for device configuration. The HistoROM offers extended functions for an embedded event logbook, including the data logging for over 1,000 points.

To vote for this technology, click here. | To return to the list of nominees, click here.

The typical readout/display in this segment is a small character, two-line LCD. With the ST100, the user gets graphical/digital, backlighted LCD readout, which continuously displays all measured parameters, flowrate, total flow, temperature and pressure, plus flowrate in a 0-100 percent bar graph and the active calibration group. For alarms, icons illuminate and flash upon a trip condition and will change to steady-state when acknowledged. The display also has an innovative writeable field in which the user can note gas composition, application name, pipe or process name, or even a tag number for quickly associating the readings with the correct process. Another unique feature of the display is that it is rotatable electronically by the user to ensure the optimum viewing angle.

The meter offers outputs of analog and bus communication, including triple 4-20mA, frequency/pulse, relays, HART (version 7), Foundation Fieldbus, Profibus-PA, and Modbus. The meter provides accuracy to 0.75 percent of reading (compared to the 1-2 percent typical in this product segment).

To vote for this technology, click here. | To return to the list of nominees, click here.

Outstanding operating characteristics include:

Unstable Process Conditions: Changes in viscosity, density, or acidity do not affect accuracy.

Agitated Surfaces: Boiling surfaces, dust, foam, and vapor do not affect device performance. Suitable for recirculating fluids, propeller mixers, aeration tanks.

Extreme Operating Limits: Performs well under extreme temperatures up to 600 F (315 C). Capable of withstanding pressures up to 580 PSIG (40 Bar)

Works with Fine Powders & Sticky Fluids: Vacuum tanks with used cooking oil. Paint, latex, animal fat, and soy bean oil. Saw dust, carbon black, titanium tetrachloride, salt, grain.

Testimonial: “The new radar system works really good; I would like to use it in a few lift stations. The [Tracer 1000/2000] is better than other products used in the past, plus there is no concern with mist.” – Kevin Smith, Chief Operator at New Philadelphia WWTP.

To vote for this technology, click here. | To return to the list of nominees, click here.

Greyline’s DLT 2.0 reduces costs and simplifies instrumentation at treatment plant headworks. Two sensor differential instruments have been in service for some time, but the DLT 2.0 feature of combining one of the sensors for the dual function of both downstream level and differential flow is a unique, cost-saving design that eliminates the need for a dedicated open-channel flow monitor. Until the DLT 2.0 was developed, treatment plants would have to buy two separate instruments to accomplish the same functions.

The DLT 2.0 Differential Level Transmitter measures level and open-channel flow with +/-0.25 percent accuracy using two non-contacting ultrasonic sensors. It is calibrated with a user-friendly keypad/menu system and includes fully programmable control relays plus three 4-20mA outputs for upstream level, differential level, and downstream level or open-channel flow. Plug-and-play data storage options are available.

To vote for this technology, click here. | To return to the list of nominees, click here.

The INKsmart unit combines filtration & metering weighing approx. 22 lbs. with package dimensions of 6.5” deep x 8” high x 9.75” long. All data is captured in real-time with dual outputs both in (network and digital). The instrument is a production tool for monitoring flow and consumption rates, time, and temperature.

Aggressive media filtration and accurate media consumption documentation is accomplished from the instrument, which is sealless in design, providing quadrature output without breaching the mechanism’s integrity. Its flow range is from 1cc of ink per minute to a maximum of 15 gallons of ink per minute. It can operate within temperature ranges is from 50 F to 200 F without compromising its 0.1 percent accuracy, and it operates effectively from 5 PSI to 4,000 PSI, producing 40 CC of measured material at 24 pulses per revolution.

The innovative precision meter package with attached filter filters media with a high-pressure built-in filter system and no filtration bypass mechanisms. Filter elements are crush-proof to 4,500 PSI with the filter canister pressure-proof up to 12,000 PSI.

Testimonial: “I’ve worked for three different printing companies in my 30 years in this industry. I know that old technology was helter-skelter for everybody. Each of the three companies tried to use the old technology, and each one tossed it out. There was a need for improvement, but the tools weren’t there. INKnet has bridged that gap, and it’s been a very solid, encouraging improvement in the industry. Since the original INKnet purchase, I’ve never even looked at any other solutions. They’ve given me exactly what I want.” – Jim Burke, Production Manager, Buffalo Newspress.

To vote for this technology, click here. | To return to the list of nominees, click here.

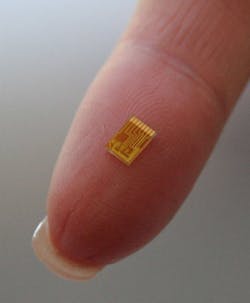

The innovation associated with the MFS02 flow sensor is derived from the polymer membrane technology that it employs. Moving from the traditional ceramic substrates of other flow sensors to the polymer membrane of the MFS02 has allowed the sensor to make extreme improvements in sensitivity and response time. The sensor has a reduced power consumption compared to older sensor models due to its low thermal mass. The MFS02 also impresses when compared to other competitive technologies on the market in regards to increased measuring range and operating temperature range, and improved handling, versatility and robustness.

Through thin-film deposition and polymer technology, Innovative Sensor Technology was able to develop the MFS02 with outstanding operating characteristics. The first noticeable quality of the sensor is its miniature size. In combination with the size of the MFS02, the use of a thin polymer layer exposed to air on both sides of the substrate at the active area has led to an extremely low thermal mass. This low thermal mass has resulted in additional outstanding operating characteristics, including sensitivity, low power consumption, low weight, and fast response time. The versatility and robustness of the sensor construction also lends itself to both high and low flow ranges, a wide operating temperature range, and a stable zero point at no flow that is resistant to contamination over time.

To vote for this technology, click here. | To return to the list of nominees, click here.

The K25-Ex Camera System is smaller than comparable video camera systems that must be mounted inside separate, bulky, explosion-proof housings. It is the most compact camera system in its class that offers high resolution for precise observation and the ability to control and contrast captured images.

Testimonials: A safety-equipment company needed video cameras that were small enough to fit inside small oil pipelines. Its equipment is used to verify that the pipes are free of residue before workers begin to repair the pipes using welders. The cameras that it had been using were installed inside separate housings to assure an explosion-proof rating. The bulky cameras made it more difficult for operators to work around the reactor, which has a lot of other equipment surrounding it. The company solved this problem by switching to the L.J. Star K25-Ex Camera System, which is the only explosion proof-rated camera system small enough to fit its size requirements that it could find.

To vote for this technology, click here. | To return to the list of nominees, click here.

Ease of hot-tap installation: The FPI Mag flowmeter installs without interrupting service, de-watering lines, cutting pipe, or welding flanges. The easy hot-tap installation makes the FPI Mag particularly cost-effective for retrofit applications, replacing flowmeters, or in sites never metered before.

Multi-electrodes deliver accurate full profile: The FPI Mag’s unique operating principle delivers accuracy unmatched by other insertion magmeters and rivals the performance of a full-bore mag meter. Continuous measurement across the entire flow profile compensates for variable flow profiles, including swirls and turbulent conditions.

Robust construction for operational longevity: The sensor body is made from heavy-duty 316 stainless steel for maximum structural integrity. An NSF-certified 3M fusion-bonded epoxy coating ensures superior long-term operation.

Virtually no recalibration or maintenance: The FPI Mag’s highly stable flow sensor comes pre-calibrated from McCrometer’s NIST-traceable calibration lab and requires no recalibration in the field. With no moving parts, the FPI Mag’s simply designed sensor contains nothing to wear or break.

To vote for this technology, click here. | To return to the list of nominees, click here.

The Prism is designed to accurately log the mass flowrate of gases, such as Natural Gas, Landfill Gas, Digester Gas, Compressed Air, and Nitrogen. When commanded, the unit will also output the stored data to a PC. In addition to having 16 Calibration Channels, the Prism also can be switched to TAG ID Mode, allowing the user to identify 99 different pipes, which require logging of the flowrate. The unique Tags that the user identifies for the pipes can be associated with any of the 16 calibrations (or configurations).

To vote for this technology, click here. | To return to the list of nominees, click here.

The meters are manufactured using low-power MEMS thermal mass flow technology that can provide digital (Modbus) interface with a large turndown ratio of 50-to-1 with an accuracy of 2 percent of readings. The meters can also be used as a stand-alone unit powered with four AA batteries. The meter head can be rotated 180 degrees for easy data access at any installation conditions. The meters are sold at below $50 with a volume.

Unlike the volumetric technology, the MF5700 meter provides mass flow (temperature and pressure automatically compensated as per the thermal mass flow principle), and therefore much more precision for the volumetric approaches. In addition to the improved accuracy – particularly during pressure or temperature changes – these meters allow users to remotely monitor the process and can also control with an optional on-off valve. Further, the user can program the meter so that the data can be stored in the memory inside the meter head for data download and analysis. The meters also provide a user-defined password for data safety.

To vote for this technology, click here. | To return to the list of nominees, click here.

The TVA incorporates an innovative moving cone design, which not only provides exceptional flow range capability; but it reshapes the flow profile to allow installation with short pipe runs. The cone’s large surface area disperses the high impact energy of wet steam, making it very resistant to erosion and reliable in the long term.

One application where the TVA is a particularly good fit is for universities that have widely variable flowrates between high winter and low summer steam loads. The TVA is capable of measuring these wide ranges in flow accurately with no modifications or required maintenance.

To vote for this technology, click here. | To return to the list of nominees, click here.

The Hot Tap Accelabar Sensor allows the nozzle and flanges to stay in place while the sensor portion is inspected. Prior to its invention, in order for the sensor portion of the Accelabar to be removed for inspection or maintenance, the process would have to be shut down and the pipe depressurized. Bringing a line out of service to inspect a sensor is very costly and time consuming.

The Hot Tap Accelabar allows for sensor inspection over any range of flows and operating conditions at 600# ANSI (1,440 PSI @ 100 F or 850 F max) or below.

Testimonial: “The Hot Tap Accelebar has provided more reliable measurement due to its high turndown capability with the added benefit of retracting and inspecting the sensor for periodic buildup common in our process environment. Prior to installation of the Hot Tap Accelebar, we used orifice plates that did not give us the necessary turndown and they cost us two days of shutdown time for inspection and maintenance.” – Ops supervisor for oil & natural gas producer.

To vote for this technology, click here. | To return to the list of nominees, click here.

CONTROL

Air-Operated, Double-Diaphragm Pumps for Semicon ApplicationsUsing PTFE or stainless steel for all outside housing parts and nonwetted parts, safety is improved because the pumps are resistant to acid mists and acid leaking. The optimized PTFE material of the diaphragm has a doubled-strength against flexural stress compared to standard PTFE, helping to reduce maintenance and production costs.

Solid housing parts are machined on modern CNC-machines, which enable the smallest possible tolerances. The solid housings absorb mechanical vibrations and noise level much better than thin-walled housings.

To vote for this technology, click here. | To return to the list of nominees, click here.

At the heart of the GF Series is Brooks’ MultiFlo, a patented technology that allows users to select new gas calibrations and full-scale ranges without the trouble and cost of removing the mass flow controller from the gas line. A major advancement over traditional single-point gas conversion factors, MultiFlo mass flow controllers typically deliver a three times improvement in accuracy through advanced gas modeling and compensation for non-ideal/non-linear gases. Selecting a new gas automatically establishes optimized PID settings for dynamic gas control, compensating for the effects of gas density and ensuring smooth overshoot-free transition between flowrates with steady-state stability. The GF Series fourth-generation MultiFlo technology continues to lead the market with the most accurate and most rangeable performance through extensive refinement and physical validation on critical process gases.

In 2010, Brooks increased the range of flowrates available on the GF Series from 3 SCCM to 30 SLPM to a new full-scale flowrate of 55 SLPM. The GF Series is offered with a 300 ms flow setting time (GF125) and one-second response (GF100/120). For applications requiring a slower flow response, a user-programmable ramp function linearly transitions the flow between set points over a period of up to one hour with a resolution of 2 ms.

The GF125 enables users to simplify and reduce the size and cost of gas panels by eliminating the need for point-of-use pressure regulators, pressure transducers, and associated hardware. Additionally, the all-metal flow path ensures compatibility with all gas media.

To vote for this technology, click here. | To return to the list of nominees, click here.

Testimonial: “The Type 8691 is ideal to retrofit any kind of piston operated pneumatic actuator. It is sturdy built and absolutely water and air tight. The Type 8691 can be setup to prevent environmental air intake with efficient installation, especially via ASI Fieldbus at an affordable price.” – A leading systems integrator, who has worked with the Type 8691.

To vote for this technology, click here. | To return to the list of nominees, click here.

The 4320 wireless position monitor is battery-powered, eliminating the need to install wires. A recently added option enables the use of external DC power. These power options make it easier to design new applications or implement into retrofit locations. Instrument calibration and commissioning is performed with a push-button and liquid crystal display (LCD) interface. The interface is protected from the environment within a sealed enclosure and supports multiple languages for ease of use.

To vote for this technology, click here. | To return to the list of nominees, click here.

The transducers work either together or independently to detect pulse interference, allowing twice the application security. Hawk’s transducers do not require contact with the product. The switch requires a simple one-minute setup and allows for remote test function.

The acoustic switch supports continuous operation in dusty, wet environments where other technologies fail. The transducers are used for blocked-chute detection in wet or dry environments.

To vote for this technology, click here. | To return to the list of nominees, click here.

SCT is the next logical development after seepex’s Smart Stator Technology. By separating the stator into two halves, seepex has optimized pumping technology. Since it was launched, the globally patent-pending innovation has been successfully installed in thousands of pump installations. Now, with the SCT technology, it is also possible to replace the rotor in just a few easy steps.

Progressive-cavity pumps with SCT no longer have to be removed from the installation for maintenance. Dismantling and reassembly of piping and the removal of other equipment components are eliminated. Due to the integrated retensioning device, a simple readjustment of the stator increases the service life of stator and rotor.

Testimonial: “Upgrading to SST has shown real benefit to the process here at Wargrave. A complete rebuild has been replaced with a simple adjustment to restore flow and we have also been able to de-rag and de-ice frozen pumps in a matter of minutes.” – Simon Mattin, Regional Maintenance Manager, Thames Valley East, United Kingdom

To vote for this technology, click here. | To return to the list of nominees, click here.

The unit is available with a Pilot Module, which is a front-mounted or hand-held control device that allows users to employ Sierra’s Dial-A-Gas technology to change flowrate, modify engineering units, or reconfigure the instrument. With the Pilot Module, the user can set zero, span, and full scale for each of 10 different gases.

With the addition of Sierra’s Compod technology, the Smart Trak 2 transforms into a network-enabled MODBUS RTU with programmable relays and analog inputs.

To vote for this technology, click here. | To return to the list of nominees, click here.

To vote for this technology, click here. | To return to the list of nominees, click here.

This adaptive technology determines the optimal diaphragm rod velocity and relays the information to an air-distribution valve at the air inlet location of the pump. The valve acts as a gated air management system, allowing only enough air to enter each inner-pump chamber. Diaphragms perform at their optimal operating point, with less air consumption. As the pump experiences air inlet fluctuations or other changes that affect air flow, the system adapts to optimize the pump’s performance.

Testimonial: “[Over a 30-day] period of time, AirVantage reduced our air consumption by 23 percent while maintaining our desired flow rates.” – Rick Klok, Plant Manager, Grains and Powders Manufacturing Facility, Saint Gobain

To vote for this technology, click here. | To return to the list of nominees, click here.

CONTAINMENT

Hybrid Connector for Fluid, Air & Electrical LinesThe Hybrid Connector includes a panel-mounted female socket for use in the device or equipment and an integral hose coupling that comes complete with an eight-inch umbilical hose, containing all wiring and fluid tubing. The fluid couplers are made from glass-filled polypropylene with stainless steel valve springs and EPDM o-rings. The external parts, such as housings and rotating collar, are also polypropylene. The hose coupling has an acetal collar that secures the tubing to the coupler. Finally, the external umbilical tubing is flexible and re-enforced PVC with PVC fluid tubes routed through the umbilical. Operating temperatures range from 40 F (4 C) to 100 F (38 C). Pressure ranges from vacuum to 45 PSI (3.1 bar).

The vast majority of the medical equipment available today has fluid, air and electrical connections carefully separated. However, so many different connections on a machine or device can be confusing for clinicians and end-users, leading to potentially fatal consequences. The innovative dry break valved fluid connectors in the Hybrid Connector have no spillage or inclusion upon disconnection, allowing fluid lines in the connector to be in close proximity to the multiple electrical contacts. Multiple connections can be made with one simple motion that is easy and intuitive for clinicians and end-users alike.

In addition, design engineers can now directly integrate hand pieces and equipment, streamlining and simplifying their product. To view a video of the Hybrid Connector in action, click here.

To vote for this technology, click here. | To return to the list of nominees, click here.

Although the Piranhaflex Plus hose provides similar PSI characteristics to other hydraulic hoses in the marketplace; its unique, specially engineered low-friction polyurethane cover compound makes it easier to rout the hoses when bundled in fork truck applications. This important characteristic, along with increased flexibility, helps to extend hose service life with less frequent replacement of hoses required.

Use of Piranhaflex Plus hoses in a fork truck application eliminates hose-sticking problems and premature cover wear due to chafing, which requires replacement hoses to be used more frequently.

Even though Piranhaflex Plus hydraulic hose is still a relatively new product in the field, similar uses of this special Piranha-made cover, used in the sewer and jetting hose industries, have already shown to provide increased wear characteristics in very tough application environments.

To vote for this technology, click here. | To return to the list of nominees, click here.

Testing has shown that Turcon M12 is resistant to virtually all media, including a broad range of lubricants, and has outstanding wear-resistance and friction characteristics. The cost-effective material also provides customers with extended seal life, as well as a wide operating window in terms of temperature, pressure and velocity.

Key to achieving maximum seal life is to make sure that sealing compounds match up to application parameters. If a material can stand up to a greater variety of conditions, this makes the compound more versatile.

Considerable R&D time was devoted to develop a PTFE-based material that is compatible with a broad range of lubricants. It also had to demonstrate minimal wear with excellent friction characteristics at extreme temperatures, high pressures, and rapid velocities.

If you don”t have a Facebook account and would like to place a vote for the Flow Control Innovation Awards, please e-mail your vote to [email protected].