Coriolis Effect Flow Meters … All You Need to Know

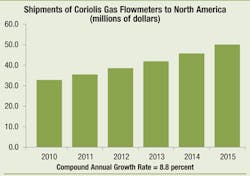

The Coriolis flow meter market has been one of the fastest growing flow meter markets over the past five years. Despite their higher initial purchase price, many users find Coriolis effect flow meters a good investment when considering total cost of ownership. As such, process plants are increasingly selecting Coriolis meters to replace differential-pressure (DP) devices, and their use is also growing in the oil & gas industry.

One of the most important features of Coriolis effect flow meters is that they measure mass flow. While volumetric flow measurement is sufficient in many cases, mass flow measurement provides certain advantages. For example, many products are sold by weight rather than by volume, and in these cases it is often desirable to measure mass flow. Chemical reactions are often based on mass rather than volume, so mass flow measurement is also often required in the chemical industry.

While both volumetric and mass flow apply to liquids and gases, mass flow is especially appropriate for measuring gases. This is because gases are more readily affected by temperature and pressure than are liquids. Pressure has minimal effect on liquids in terms of compressibility, and is often ignored in making volumetric measurements of flow. The effects of temperature on liquids are also often disregarded, except where high accuracy is desired.

Whereas magnetic flow meters provide accuracy in the range of 0.5 percent, many Coriolis flow meters achieve accuracy of 0.1 percent. It is the high accuracy of Coriolis flow meters that is one of the major reasons for their extremely rapid growth over the past five years. Companies that need flow meters for custody transfer, or want highly accurate measurement of mass, have a good reason to select Coriolis flow meters.

What Is the Coriolis Effect?

Coriolis flow meters are named after Gaspard Gustave de Coriolis, a French mathematician and engineer. In 1835, Coriolis wrote a paper in which he described the behavior of objects in a rotating frame of reference. While this is sometimes called the Coriolis Force, it is more accurately called the Coriolis Effect, since it is not the result of a force acting directly on the object, but rather the perceived motion of a body moving in a straight line over a rotating body or frame of reference.

READ ALSO: Coriolis Flow Meters for Gas Measurement

One common example given to illustrate the Coriolis Effect is that of a ball propelled through the air a long distance in a straight line from the North Pole toward a target on the equator. By the time the ball arrives at the equator, it will not land at its apparent target, because the earth will have rotated sufficiently underneath the moving ball so that it will land some distance away from the perceived target on the equator. From the perspective of the person standing where the ball is "thrown," the ball will appear to have curved.

A similar example is someone throwing a ball from the center of a rotating merry-go-round. If she throws the ball at a horse on the edge of the merry-go-round, assuming the merry-go-round is rotating at a rapid pace, she will not hit the horse she is aiming at but perhaps the one after it, since the horse she aimed at will have moved by the time the ball reaches the edge of the merry-go-round.

WEBINAR: Advancements in Coriolis Flow Meter Technology

In both these cases, there is no force acting to push the ball in a curved direction. Instead, its motion will appear to be curved from the perspective of the ball-thrower because the frame of reference is moving underneath the ball. This is why the Coriolis "force" is more appropriately called the Coriolis Effect. It refers to the apparent effect on the motion of an object passing over a rotating frame of reference when viewed from the perspective of the point of origin of that moving object.

Do Coriolis Flow Meters Embody the Coriolis Effect?

If Coriolis flow meters embody the Coriolis Effect, it is logical to assume that they must have rotating tubes. Yet it is not clear why fluid passing through rotating tubes would have a Coriolis Effect on the motion of the tubes, since the effect of the fluid is simply the result of inertial motion on the tubes. But in the Coriolis Effect, there is no force exerted on the ball thrown on the earth or the merry-go-round apart from the force exerted in throwing the ball. The ball simply appears to curve when viewed from the perspective of the rotating body.

Custody Transfer of Natural Gas Is a Potential Boom Market for Coriolis Flow Meters

Custody transfer of natural gas is a fast-growing market, especially with the increased popularity of natural gas as an energy source. Natural gas changes hands, or ownership, at a number of points between the producer and the end-user. These transfers occur at custody-transfer points and are tightly regulated by standards groups such as the American Gas Association (AGA). Other geographic regions have their own regulatory bodies.

One important function of the AGA and the American Petroleum Institute (API) is to lay down technical standards or criteria for sellers and buyers to follow when transferring ownership of natural gas and petroleum liquids from one party to another. In the past, these groups have published reports on the use of orifice-plate meters and turbine meters for use in the custody transfer of natural gas. The importance of these reports is illustrated by the example of ultrasonic flowmeters. In the mid-1990s, a European association of natural gas producers called Groupe Europeen de Recherche GaziSres (GERG) issued a report laying out criteria to govern the use of ultrasonic flowmeters in the custody transfer of natural gas. This resulted in a substantial boost in the sales of ultrasonic flowmeters for this purpose in Europe. In June 1998, the AGA issued AGA Report 9, which also gave criteria for using ultrasonic flowmeters in natural gas custody-transfer situations. This caused a substantial boost in the sales of these meters for that purpose, especially in the United States. The market for using ultrasonic meters to measure natural gas for custody transfer is now the fastest growing segment of the flowmeter market.

The API has also issued a draft standard entitled "Measurement of Single-Phase, Intermediate, and Finished Hydrocarbon Fluids by Coriolis Meters." A second draft standard, called "Measurement of Crude Oil by Coriolis Meters," has also been approved by the API.

Suppliers have made a number of improvements in Coriolis technology over the past five years. Coriolis meters are now much more capable of measuring gases than previous generations of Coriolis technology. The majority of Coriolis suppliers now have meters that can measure gas flow. Straight-tube meters have become more accurate and reliable, thereby addressing some of the drawbacks of bent-tube meters. These include pressure drop, the ability to measure high-speed fluids, and the tendency of bent tubes to impede the progress of fluids.

Proponents of the Coriolis theory also cite a similar example when trying to explain the Coriolis Effect. They point to a hose full of water that is held in someone’s hand. When no water is running through the hose, it remains still. But as water runs through the hose, the hose starts to twist and turn, due to the inertial effect of the running water on the hose. This is very much like the action of fluid on Coriolis flow tubes, but it is not clear why this is an example of the Coriolis Effect. Of course, rapidly flowing fluid through a narrow flexible object like a hose will cause it to twist and turn, due to the inertia of the fluid. If the pipes that carry many of the liquids in a plant were flexible instead of rigid, and the flow velocity was high enough, they would twist and turn as well. But what does this have to do with the Coriolis Effect?

How Coriolis Flow Meters Actually Work

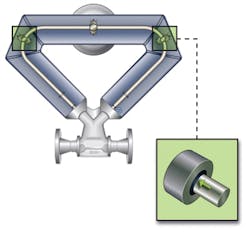

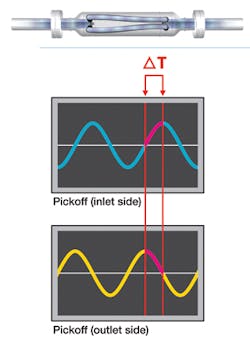

Instead of having a rotating frame of reference, Coriolis flow meters work on the principle that the inertia created by fluid flowing through an oscillating tube causes the tube to twist in proportion to mass flowrate. Many Coriolis flow meters have two tubes. They are made to vibrate in opposition to each other by means of a magnetic coil. Sensors in the form of magnet and coil assemblies are mounted on the inlet and the outlet of both flow tubes. As the coils move through the magnetic field created by the magnet, they create a voltage in the form of a sine wave. These sine waves are the key to measuring mass flow.

Under no-flow conditions, the inlet and outlet sine waves are in phase with each other. When fluid is moving through the tubes, the tubes twist in proportion to mass flowrate. The amount of this twist is detected by the inlet and outlet sensors, based on a phase shift (time difference) that occurs in the sine waves formed by the two sensors. The mass flowrate is derived from the difference in phase shift in the sine waves formed by the inlet and outlet sensors.

Coriolis Effect Flow Meters or Inertial Mass Flowmeters?

It is difficult to see the relation between the Coriolis Effect and the inertial principle upon which Coriolis flow meters actually operate. However, this doesn’t cast doubt on their effectiveness or undermine their theory of operation. It simply calls into question whether they are appropriately named, and what connection the inventors of this meter saw between the Coriolis Effect and the inertial operation of Coriolis meters. Perhaps they saw the Coriolis Effect as a type of metaphor or analogue to the inertial force exerted by fluid flowing through a vibrating tube.

Coriolis flow meters do have a kind of mystique about them that no other flow meter has. It may be due in part to the difficulty people have in understanding how they operate. Also, manufacturers typically enclose the sensors inside a container, concealing their inner workings. No doubt, part of this mystique is that they are the most accurate flow meter and they do the measurement with no moving parts, apart from the vibration of the tubes.

Recent Developments in Coriolis Flow Measurement

Regardless of what one calls the principles that form the basis of Coriolis flow meters, there is no denying that these flow meters are playing an increasingly important role in the flow meter market today. One important development is the introduction of large-line-size Coriolis flow meters. Formerly, only Rheonik produced Coriolis flow meters for line sizes above six inches. Following Rheonik’s introduction of large-line Coriolis flow meters, Micro Motion, Endress+Hauser, and KROHNE have all entered this market. While all Coriolis flow meters above six inches are large and somewhat unwieldy, they have been selling well enough to have a significant impact on the market.

Despite their hefty price tag, 8-, 10-, and 12-inch Coriolis meters, many of which are designed for custody-transfer applications, are selling well in the oil & gas industry. Most recently, Endress+Hauser has introduced a 14-inch Coriolis flow meter designed for custody-transfer applications. End-users are willing to pay a higher price for the high accuracy and reliability of Coriolis flow meters when measuring high-value products like crude oil. Likewise, end-users pay a high initial price for ultrasonic flow meters for custody transfer of natural gas, because they want the high accuracy and reliability of ultrasonic meters. In both these cases, lifecycle costs outweigh initial purchase price considerations.

While most of the large-line Coriolis flow meters use the traditional bent-tube design, KROHNE has introduced a large-line Coriolis meter using its straight-tube Coriolis design. While this meter is somewhat longer than the bent-tube meters, it is less bulky because the straight-tube design requires less space. This may prove to be a strategic advantage to KROHNE in the competition for the large-line-size Coriolis flow meter market.

Jesse Yoder, Ph.D., is president of Flow Research Inc. in Wakefield, Mass., a company he founded in 1998. He has 24 years of experience as an analyst and writer in process control. Dr. Yoder specializes in flow meters and other field devices, including pressure and temperature products. He has written over 150 journal articles on instrumentation topics. Dr. Yoder can be reached at [email protected].

For more information on Flow Research’s research in the area of Coriolis flow measurement, see FlowCoriolis.com.

Jesse Yoder

Jesse Yoder, Ph.D., is president of Flow Research Inc. He has 30 years of experience as an analyst and writer in instrumentation. Yoder holds two U.S. patents on a dual-tube meter design and is the author of "The Tao of Measurement," published by ISA. He may be reached at [email protected]. Find more information on the latest study from Flow Research, "The World Market for Gas Flow Measurement, 4th Edition," at www.gasflows.com.