| Related Content: 2012 Innovation Award Nominees |

Flow Control is pleased to introduce the 2012 Flow Control Innovation Award winners based on reader votes received through Aug. 1. The 11 technologies presented here represent novel solutions for fluid handling applications in the categories of fluid measurement, control and containment. We hope you enjoy discovering, in the following technology summaries, what makes these winners worthy of this year’s honors. Case studies/application stories on each winner will be presented in the October issue of Flow Control.

We thank all who participated in this year’s Flow Control Innovation Awards program from nominating a new technology to casting a vote for your favorite novel solution. Look for details about the 2013 program to be announced soon.

2012 Innovation Award Winners

Graco

ML One Primary Gas Flow CalibratorBios International’s ML One measures gas flowrates from 5 to 50,000 SCCM with an accuracy of 0.15 percent. The ML One can measure almost any gas, inert or corrosive. The operating temperature range is 15 C to 30 C, and the gas pressure range is 14 to 16 PSIA. The ML One can be placed on a cart and moved to allow highly accurate gas flow measurements in factory applications. Operation of the ML One is intuitive and simple—a typical gas flow measurement only requires the user to connect the gas flow and touch “Measure” on the screen followed by “Start.”

The ML One is based on proven technology of measuring the flowrate of a gas by displacing a piston in a tube. Gas flowrate is determined by the speed of piston displacement, the gas pressure, and the gas temperature. Previous instruments use a piston in a vertical tube with the gas flow lifting the piston. The ML One design uses horizontal tubes.

WHAT’S INNOVATIVE?

A very light low-friction piston was engineered for the horizontal tube design, and valves now alternate the gas flow direction through the tube. As gas flows, optical sensors measure the piston oscillation across the tube. The result is substantial improvements in measurement accuracy, portability, reduced pressure changes during readings, more than twice the reading speed, and improved reliability.

Proline Prosonic Flow B200 Ultrasonic FlowmeterEndress+Hauser’s Proline Prosonic Flow B200 is an industry-optimized ultrasonic flowmeter that measures the volume flow of raw biogas produced from sources such as anaerobic digesters, landfill operations, and coal beds. Biogas is variable in composition, at or near atmospheric pressure, dirty, wet, and potentially corrosive. These conditions limit accuracy and reliability with other flow measurement technologies, but the B200 is designed to stand up to these conditions with a two-wire, 4-20mA HART, loop-powered ultrasonic flowmeter providing multivariable measurement of volume flowrate, temperature, and methane content.

With the Prosonic Flow B200, it is now possible—using precisely measured sound velocity and an integrated temperature sensor—to simultaneously measure the methane content directly in the pipe and calculate related parameters, such as calorific value and energy flow, without the need for additional devices.

WHAT’S INNOVATIVE?

Most unique to this device is its ability to continuously compute methane content with no additional inputs required.

This meter offers many advantages over traditional inline meters. The TransLoc system allows proper and secure mounting of the transducers while protecting them from harsh environments. With an IP65 enclosure rating and the use of dry couplant, high performance with minimal maintenance is guaranteed. The flowmeter is capable of measuring almost any hydrocarbon liquid at viscosities up to 2,800 CST, as compared to the typical 300 CSTt limit of inline meters. The flowmeter’s non-intrusive nature allows for pigging without removal of the transducers. Another advantage is that cavity build-up (ranging from carbon to paraffins) will not occur.

WHAT’S INNOVATIVE?

Its ability to measure the flow of gas or liquid hydrocarbons using non-intrusive ultrasonic transducers, and the fact that it is the first flowmeter of its kind to offer custody-transfer accuracy.

VISCOLINE Inline Viscosity Measurement DeviceKROHNE’s VISCOLINE is a patented instrument that allows the measurement of viscosity inline. Viscosity is a critical variable for the control of several industrial processes. Knowing real-time viscosity and controlling an industrial process accordingly increases productivity and optimizes the quality of finished products.

It has always been difficult to measure the viscosity of non-Newtonian fluids, because their viscosity depends on the precise flow conditions occurring at the measurement. The same fluids flowing at two different flowrates in a pipe give two different viscosity measurements. The explanation of such behavior is found at the microscopic level—it is related to the interaction of the molecules and their mutual arrangement. For example, as the shear rate increases, molecules tend to align themselves in the flow direction, with less resistance to flow. This molecular rearrangement may take some time to fully develop. A yogurt sample removed from a process pipe or through a sampling valve may take several minutes (or more) to stabilize, and only after this time can there be a stable and repeatable viscosity measurement on a laboratory rheometer. VISCOLINE is the only instrument capable of measuring this viscosity function on line.

WHAT’S INNOVATIVE?

No mechanical modification is required for accurate measurements of different fluids. The innovative VISCOLINE uses patented technology based on mixing principles applied to pipes. Bulk viscosity is measured on a whole flow section, which is re-homogenized by the action of static mixers.

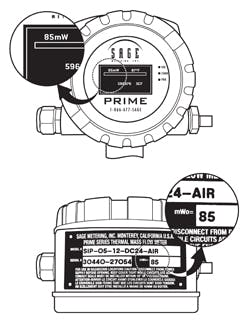

The main difference with this process is that it allows the customer to perform calibration verification on the flowmeter within minutes. In the past, the customer had to send the flowmeter back to the factory for annual calibrations, or they would have had to hire a contractor to remove the meter to conduct third-party verification. The Sage method not only verifies calibration for the entire flow range, but also eliminates errors that are attributed to sensors that become contaminated.

WHAT’S INNOVATIVE?

The product offers a digital method of driving the flow sensors, resulting in enhanced signal stability, improved temperature compensation, greater sensitivity to flow changes, and improved resolution. As a result, a stable zero flow (0 SCFM) can be used as a checkpoint to verifying the meter’s accuracy.

CONTROL

WHAT’S INNOVATIVE?

Innovation on this product can be highlighted in three areas: Lower power consumption with increased pressure ratings; one valve meets global approvals and certifications; and valves do not require special filtration. It complies with ANSI/ISA 7.0.01, 1996 quality standard for instrument air defined as clean, dry air or inert gas with max particle size of 40 micrometers. Other products on the market require special more expensive filtration that reduces the particles size to 5 to 20 micrometers.

MBV Series Instrumentation Metering Ball Valve Ham-Let’s MBV Series instrumentation metering ball valve is a compact design for high-precision sensitive flow regulation, integrated with a leak-tight soft seal shut-off control. The product provides the functionality of a ball valve (shut-off) and a needle valve (metering) in one compact package.

The heart of the MBV series is a patent-pending design that allows users to achieve various control configurations, with a very fine and sensitive needle for flow regulation and calibration, while also including a diverting option for shut-off or full-flow position, without loading or damaging the sensitive regulation needle. Previous to this product, users would mount a shutoff valve in series with a metering valve to control critical flows. This required additional tubing or piping segments as well as additional connection points, all of which are potential leak points. Ham-Let’s MBV eliminates these requirements and results in a more efficient flow control scheme with a smaller footprint. The MBV series patent-pending design allows a basic and common configuration of metering/shutoff. Additional configurations offer a metering/full flow and metering/shutoff/full flow.

The MBV series is pressure-rated up to 2,000 PSIG (138 barg) and temperature rated up to 3,000 F (1,38O C). A main application for this product has been controlling flow inputs to industrial analyzers.

WHAT’S INNOVATIVE?

The MBV series allows fine metering and shut-off control without requiring multiple devices in line. This eliminates tubing work and tube connections. In addition, the use of MBV reduces the system’s weight, internal dead volume, footprint, connectors, labor costs, troubleshooting costs, and more.

Cake Pump System with Load Cell seepex has a contained cake transfer solution which replaces the open-air cake transfer method using conveyors. Dewatered sludge cake from a belt press or centrifuge falls into the hopper of a seepex Progressive Cavity Pump. The hopper is fitted with load cell sensors, which detect the increase in weight and adjust the speed of the pump accordingly. The pump will increase or decrease production as needed; when the belt stops feeding the hopper, the pump will turn off. The system is also fitted with a pressure sensor, dry running protection sensor and a boundary layer injection system. seepex also provides an engineered control panel to ensure properly functioning components. All pieces together make up the seepex Cake Pump System.

The conveying capacity of the pump used within the system is 0.5 m3/h-130m3/h (2.2 GPM-572 GPM). The pressure capability of the pump is up to 36 bar (540 PSI). There are several different ranges and sizes of pumps, which are custom-applied to each application. These pumps incorporate an open hopper and auger feed screw, which enables highly viscous products to be fed into the pumping elements. The pitch and diameter of the auger can be adjusted according to operating conditions for optimal product feed and the compression housing is removable for service work.

WHAT’S INNOVATIVE?

The product integrates many components, which are necessary with cake transfer, into one package. Conveyors are actively used, however, in comparison, conveyors are messy and very expensive to install and maintain. This system keeps the cake contained within piping. The load cells automate the process. The pump knows when to speed up and slow down, which saves energy consumption.

The flushing process is optimized by offering a range of valve sizes available from 1/2-inch/15 mm to 12 inches/300 mm to provide the correct velocity to pull or draw fresh water into a zone. This, coupled with the pressure-sustaining feature, scours and cleans pipes, which reduces corrosion and dramatically improves water quality. Each TAPS unit includes a water sampling port so that onsite clarity and testing can be easily seen and sampled without disrupting the process.

WHAT’S INNOVATIVE?

TAPS has a unique pressure-sustaining feature to ensure minimum upstream pressure is maintained for system needs and in the event that fire flow is needed. TAPS has a hydraulically operated valve that introduces or releases water from the control chamber above the diaphragm to maintain accurate water flow.

WHAT’S INNOVATIVE?

The SmartTrak 140 mass flow controller is a hybrid of two innovative technologies—Sierra’s SmartTrak 100 Series with its SmartTrak inherently linear Laminar Flow Element (LFE), sensor and digital electronics and Sierra’s industry staple SideTrak 840’s low ΔP with its large flow coefficient (Cv) valve, which is a measure of how “easily” or efficiently flow goes through the valve. By combining these two technologies, the SmartTrak 140 boasts the smallest pressure drop in the industry and includes all the features of Sierra’s flagship SmartTrak 100 Series.

CONTAINMENT

Sanitary Drum Unloader for High-Viscosity Materials Graco’s SaniForce drum unloaders are best suited for unloading high-viscosity materials out of 55-gallon drums. A SaniForce drum unloader can easily evacuate and transfer tomato pastes and peanut butters, personal care products like lotions, and cosmetics like mascara. Today, many food and personal care processors have someone manually scooping product out of a drum; others are chaining or clamping the drum, raising it and then dumping the product into a kettle or hopper. They then spray water to evacuate the residual material from the bottom and sides of the drum, which can dilute the product. The SaniForce drum unloading system provides a safe solution that improves both plant efficiency and productivity.

The typical evacuation time for a drum unloader is about five minutes vs. comparable processes that take over 30 minutes. A high performing drum unloader will leave less than 1 percent residual product in the bottom of the drum.

WHAT’S INNOVATIVE?

An important advancement introduced with the Saniforce drum unloader is the creation of the inflatable wiper seal technology on the ram plate. After the ram plate and seal enter the drum, the user turns a dial, which inflates the seal to the appropriate pressure. The seal holds this pressure and gently scrapes the side of the drum as the ram plate moves from top to bottom. This is a main reason users can achieve greater than 99 percent evacuation rates; the inflatable seal prevents product “blowing by” the ram plate—something that a flat wiper seal cannot accomplish. Also, with this inflatable seal, the drum unloader can accommodate both straight-sided and tapered drums.

EDITOR”S NOTE: All who voted in this year”s Flow Control Innovation Awards program were entered into a raffle for an Apple iPad. Congratulations to raffle winner Mary Mertes, Air Monitoring Chemist, Wisconsin Department of Natural Resources.

Look for case studies on each winning technology above in the October 2012 issue of Flow Control magazine.