Magmeter Basics

Electromagnetic flowmeters (magmeters) perform well in many processing applications, making up about 20 percent of installations worldwide (Source: Flow Research, FlowResearch.com). The fluid measured, however, must be a conductive liquid or liquid slurry. The standard minimum conductivity level for magnetic flowmeters is 5 microS/cm. Some specialized magmeter designs allow for the measuring of process liquids with lower conductivities, but these applications should be discussed with factory applications engineers.

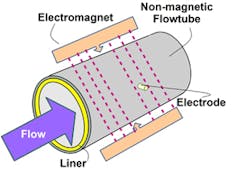

According to Faraday’s Law, an electrical conductor moving through a magnetic field produces an electric signal within the conductor. In the case of magmeters, the liquid is the conductor, and electromagnetic coils surrounding the flow tube generate the magnetic field. Two electrodes embedded on opposite sides of the flow tube pick up the signal. The flow signal at the electrodes is directly proportional to the flow velocity, the intensity of the magnetic field, and the width of the pipe (distance between electrodes).

The main advantages of magmeters are the obstructionless design, linear signal output, corrosion-resistant wetted parts, and high accuracy. Because the liquid flowing through the meter meets no obstructions, the pressure drop through the meter is virtually zero. Magmeters have no moving parts to wear. The only wetted parts are the electrodes, insulating liner, and a grounding ring (if needed). Instrument engineers can select these parts for compatibility with the most corrosive of chemicals. In addition, these selections can meet the sanitary requirements for many food and pharmaceutical applications. Accuracy over a wide flow range (100-to-1) can be as good as +/- 0.2 percent of rate. Lastly, magnetic flowmeters are now often equipped with digital signal processing (DSP), which minimizes or eliminates noise issues that can lead to performance degradation.

Magmeter Construction

The electromagnetic coils that produce the flowmeter’s magnetic field typically surround the outside of a nonmagnetic pipe section called the flow tube. An alternating or pulsed direct current passing through the coils generates a magnetic field within this tube. The liquid or slurry passes through the flow tube perpendicular to the plane of the magnetic field. A metal meter body is generally made from 304 stainless steel, which has strict non-magnetic properties. This allows the magnetic field to pass through the meter body into the pipe area to develop the flow signal.

An insulating liner installed between the meter body and the electrodes prevents the flow signal from being shorted out. Generally the voltage developed across the electrodes is in the millivolt range.

An associated transmitter (converter) amplifies the raw signal and processes it to minimize electrical noise. It then converts the processed signal to a usable standard milliamp (4-20 mA) or frequency (0-10,000 Hz) output for sending to an indicator or controller. The transmitter may be mounted directly on the magmeter. Alternatively, it can be connected via a shielded cable to a remotely located transmitter.

Generating Magnetic Fields

The electromagnetic coils generating the magnetic field around the flow tube typically employ either AC or pulsed DC excitation. With most AC-excitation techniques in the U.S., 60 Hz, 110- or 220-line voltage powers the magnetic coils. The resulting flow signal has the same sine wave shape, and its amplitude varies directly with flow velocity. The coil current in AC designs is high (typically 3.2 amp). This provides a good signal-to-noise ratio, making AC designs relatively insensitive to noise from external influences.

AC-excited magmeters have a disadvantage in that they are inherently prone to zero drift. Because the magnetic field is changing rather than constant, non-moving wires and other conductors within the field of an AC system can also produce a signal voltage unrelated to flowrate. To compensate for changes involving non-moving conductors (for example, new conductive coatings on the electrodes), operators must periodically shut off flow and re-set the transmitter for zero output.

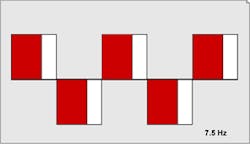

Pulsed-DC coil excitation designs essentially eliminate the zero drift issue. In this case, a lower frequency square-wave pulse (typically 7.5, 15, or 30 Hz) excites the magnetic coils. The transmitter reads the flowrate while the magnetic field is held constant. In this case, nonmoving conductors do not contribute to the measured flowrate signal. So zero drift need not be a problem for pulsed-DC designs. In addition, between pulses (no electromagnetic excitation), the transmitter sees only noise from other sources, permitting noise cancellation after each cycle.

Pulsed-DC magmeters can offer 0.2 to 0.5 percent accuracy and low power consumption. The low coil current (0.1 to 0.5 amp) comes with small square-wave signal and low signal-to-noise ratio. To compensate for the poor signal-to-noise ratio, users generally highly damp the flow signal from pulsed DC-magmeters to smooth it, increasing the meter’s response time.

Because the magnetic field is off during part of the cycle, the meter may randomly catch only part of a spike in flowrate (such as from pulsating flow), which affects accuracy. As such, pulsed-DC magmeters are not well suited for pulsating flows.

Although pulsed-DC is currently the predominant magnetic field excitation, it has not entirely replaced AC designs. Basically, the pulsed-DC system is superior in terms of zero stability, and the AC system excels in noisy applications that require high signal-to-noise ratio and improved response times.

New AC-excited magmeters from ABB are designed to effectively deal with zero drift, combining the advantages of both excitation techniques. In addition, since the coil excitation is synthesized asynchronously, the signal processor can reject all signals that do not fit within the expected envelope of frequency and shape. This mode of operation greatly rejects noise caused by entrained air and particles. Digital electronic filters with sharp drop-offs minimize the effects of hydraulic and line noise.

Some of these new-generation AC magmeters address zero drift by directly measuring the strength of the magnetic field with a magnetometer (search coil). The magmeter uses this measurement to control and holds AC magnetic field intensity constant. As a result, it offers improved flowrate measurements in applications involving vibration, slurries, entrained gas, temperature fluctuations, and pulsating flows.

Proper Magmeter Installation

Engineers consider the nature of the liquid being measured when determining meter size. Sizing determines the fluid velocity through the meter. Recommended flow velocities are 3 to 15 ft/sec for water and clean chemicals, 3 to 6 ft/sec for abrasive fluids, and 6 to 12 ft/sec for coatings and liquids with entrained air.

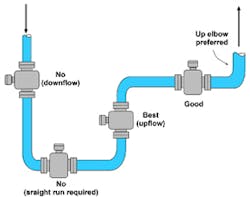

The preferred magmeter orientation is vertical or sloping with upward flow. Acceptable (and perhaps most common) is horizontal. The installation should ensure that the magmeter is filled with process liquid at all times during flow measurement. A vertical upward flow installation assures a filled magmeter under low-flow conditions. It also minimizes wear of the meter liner by abrasive particles. Electrodes should be oriented so that they are not at the top of the pipe in a horizontal or sloping installation. This prevents entrained air from coming in contact with the electrodes and causing errors in the flow signal.

Magnetic flowmeters are forgiving, but not immune, to piping configurations. Basic guidelines are available to cover elbows, control valves, blocking valves, pumps, and reducers. The upstream side is more critical. Locating a device as close as two pipe diameters downstream from the magmeter is acceptable in most cases. If possible, locate control valves downstream from the magmeter. Minimum distances in pipe diameters discussed below measure straight runs of pipe from the center line of the magmeter to the mating flange of pipe fitting for upstream components:

- Elbows: three

- Control valves and pumps: ten

- Tees: five to ten pipe diameters, depending on whether the major flow direction is in line or perpendicular to the flow through the magmeter.

Using pipe-fitting reducers to match a smaller diameter magmeter has little effect on accuracy. Reducers (concentric or eccentric) of eight degrees or less have often been installed immediately upstream of the magmeter with little or no negative effect.

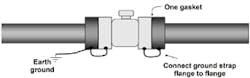

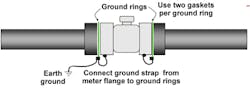

The installation should ensure that the magmeter is properly grounded and in electrical contact with the process liquid. If the adjacent piping is conductive, the grounding straps can be attached between the flanges of the magmeter and then to a good earth ground. If the pipeline consists of a nonconductive material, or is lined with one, then grounding rings or similar conductive devices should be installed to create a conductive path between the magmeter body and the process liquid. In this way, stray currents travel along the pipeline in the process pass from the liquid to the grounding ring to the body of the magmeter and back to the process on the other side of the magmeter, following the path of least resistance.

Variations

The early 1980s saw the development of a compact (wafer) magmeter style having a flowtube with no flanges. It bolts between two flanges in the adjacent piping. Overall, this style lowers the installation cost and has become popular for many applications.

Additional variations include magmeters for partially filled pipe and high-speed batching. The former measures both flow velocity and level within the pipe. Magmeters for high-speed batching incorporate software specifically designed for filling and batching operations. The software tracks time and flowrates for filling a specific volume, and looks at historical trends to decide valve opening and closing times.

Certain manufacturers now offer magmeters with calibrations that may be checked in place. These techniques electronically verify the calibration state of magmeters without interfering with their normal operation. The alternative is removing and shipping a magmeter back to the factory for calibration, which is especially expensive for large devices.

Some magmeter/transmitter combinations with this feature come to the user with a factory-supplied "fingerprint."

Periodically, a test instrument operated by a technician compares a multitude of internal parameters against the original factory values. Fingerprinted technology verifies the original calibration – a check that is traceable to NIST. The techniques can identify and report on any deviations from the required settings and can predict future problems based upon historical trends. Of course, if the magmeter fails this check, it must be returned to the factory for servicing.

Ron DiGiacomo manages business development for flow technologies in North America for ABB Inc. He has 25 years of experience in process instrumentation and control, primarily in flow measurement.