Developments solve sensor problems in food and beverage industry

Pressure measurements in food and beverage production are typically focused on monitoring and controlling line pressures, tank levels and flows. Because pressure is used in these three common applications, it is one of the most widely used measurements throughout the process industries.

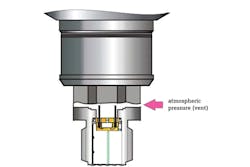

When exposed to clean in place/sterilize in place (CIP/SIP) processes, pressure sensors (see top photo) can be compromised. This article explores methods for dealing with condensation and calibration drift caused by CIP/SIP and other factors.

The regulatory world

In addition to dealing with process conditions, food and beverage production must meet strict regulatory compliance, product quality/safety and production uptime requirements.

Compliance with federal, state and local regulations is critical. Failure to meet minimum regulatory guidelines regarding accurate and thorough measurement of process variables can result in penalties ranging from monetary fines to shutting down facilities, and in extreme cases, criminal charges against facility personnel.

Product quality and safety, which is closely related to regulatory compliance, is important to plant operators for obvious reasons. Consumers expect food and beverage products to meet certain standards of quality regarding taste, texture, appearance and smell. Failure to meet these quality expectations can result in consumers purchasing competitive products. More importantly, failure to meet product safety standards can result in costly product recalls. A poor safety record and/or product recalls can drive consumers to other competitive/alternative products.

Production uptime is the ability to keep a process running as long as possible to produce the maximum amount of product in a safe manner while meeting all regulatory compliance requirements. It is important because it allows a facility to produce enough of the food and/or beverage product to meet market demands.

Figure 1. A vent in the housing of a pressure instrument allows the sensor to "breathe."

If pressure sensors drift out of calibration or drift because of condensation, pressure readings can be so far off they could endanger regulatory requirements or even shut down a process.

Drift occurs when the measurement strays (or "drifts") from actual process conditions. Since the deviations associated with drift are not typically large, they can be difficult to identify, leading to the possibility of operating processes in unacceptable conditions without realizing it. For this reason, food and beverage process owners should be keenly aware of conditions that can cause measurement drift and take proper steps to minimize those conditions or select instruments that are less susceptible to drift in those conditions.

Pressure measurement issues

Next to temperature, pressure is one of the most common process variables measured in food and beverage production. Pressure measurement is most commonly used for three reasons:

- Pressure readings in pipes and vessels

- Hydrostatic level measurement in tanks

- Flow measurements derived from differential pressure

In all three applications, plant operators need pressure instruments suited to the specific demands of food and beverage applications to produce reliable and repeatable measurements.

Good pressure measurement practices use sensors designed to meet the application’s requirements and deal with process conditions encountered — such as condensation and calibration drift.

When using pressure for hydrostatic level measurement on vented tanks, it is necessary for the instrument to "breathe." That is, the low-pressure side of the sensor needs to be exposed to ambient pressure — usually via an internal capillary and vent in the housing (see top photo). This leaves the instrument vulnerable to condensation that can plug the vent and leave the instrument susceptible to potential drift and subsequent loss of measurement reliability.

Food and beverage processes are particularly susceptible to calibration drift because many of the processes run CIP/SIP processes that produce sudden temperature shocks to the pressure instrument. This can lead to significant errors caused by drift.

Sudden temperature shocks can cause measurement drift from density changes in the fill fluid around the sensor and an inability of typical pressure transmitters to respond fast enough to those changes to correctly measure pressure during such upset conditions.

Condensation causes drift because of potential plugging of the atmospheric venting required to make gauge pressure measurements. When the atmospheric vent is plugged, the sensor is no longer referenced to local atmospheric conditions. This can lead to periods of measurement drift until the transmitter "dries out" and the sensor references actual atmospheric pressure conditions again.

High-temperature conditions typically go away once the instrument has had time to come to equilibrium. But a common problem is that plant maintenance personnel trim the instrument output to eliminate the error before the instrument recovers, thus locking in the drift error rather than eliminating it.

To allow the instrument to come back to equilibrium, downtime must be added between cleaning cycles or other high-temperature events to allow the instruments to recover. This can have significant impact on process uptime when the number of pressure instruments on such applications is considered, along with the time required for each to return to equilibrium.

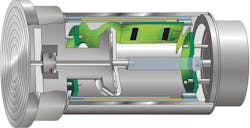

Figure 2. A condensation-resistant pressure instrument — such as this Endress+Hauser Deltapilot with a Contite sensor — is impervious to condensation-related drift because it has no vent to ambient air. The green section is a low-pressure side diaphragm.

Solving condensation and drift issues

Manufacturers provide several unique solutions to specifically address condensation issues with pressure instruments. Typically these are identified as "condensation-resistant" — or something similar — pressure instruments (see Figure 2).

For example, Endress+Hauser’s Deltapilot pressure instruments with Contite sensors are designed to provide a solution for measurement issues created by condensation within food and beverage facilities. The sensor makes the instrument impervious to condensation-related drift and allows it to respond quickly to temperature shifts caused by CIP/SIP processes.

The sensor is a standard piezoresistive sensor element with a metal process diaphragm and appropriate fill fluid. Where it differs from standard pressure instruments designs is on the low-pressure side. Rather than a vent and capillary bringing ambient pressure directly to the low-pressure side of the sensor, the Contite sensor has a low-pressure side diaphragm that provides a hermetically-sealed pressure sensor impervious to condensation.

The capillary allowing the sensor to "breathe" is a porous tube running from the vent to the low-pressure side diaphragm through a desiccant chamber. This ensures completely dry air reaches the sensor diaphragm, so no plugging of the capillary can occur because of excess moisture from condensation.

The following types of sensors provide advantages for food and beverage plants:

- Hermetically sealed sensors are condensation- and climate-proof, reducing drift errors.

- An internal temperature sensor with process temperature correction in the instrument provides excellent accuracy, long-term stability and response time — even during and following CIP/SIP cycles.

- Remote transmitter electronics are available for easier installation in extreme washdown areas and/or to provide access in hard-to-reach locations.

Universal process connections

Approximately 50 percent of all product recalls in the food and beverage industry are related to microbiological contamination because of inadequate hygienic installations. Using the correct hygienic process connection is critical to avoiding possible contamination that results in costly product recalls.

A standard universal process connection (see top photo) allows for hygienic and nonhygienic pressure sensors to be mounted to a pressure instrument. The universal process connection is simply a thread connection on pressure instruments that includes a flush-mounted process diaphragm.

An instrument with a universal process connection can be threaded to a wide variety of process connection adapters, allowing it to be mounted directly to virtually any pipe or tank.

Figure 3. Tri-clamp hygienic process connector

Pressure instruments with universal process connections provide advantages:

- Wide variety of process adapters (hygienic and non-hygienic) available.

- Short (2-inch) and long (6-inch) versions are available to accommodate almost any vessel or piping configuration.

- The flush-mounted diaphragm allows for installation with a true hygienic process adapter such as tri-clamp (see Figure 3) and varivent.

Once put into service, pressure instruments have a finite lifespan before they need to be replaced. This is often because of fatigue of metal diaphragms from repeated on/off pressure cycles and temperature shifts in the routine process operations of food and beverage production. For this reason, facilities often keep a stock of standard instruments for quick replacement when needed.

These instruments are often unique for specific applications because of the need for different process connection types within the same facility. This can lead to often high and costly stocking levels to keep a facility running at peak efficiency.

If the plant standardizes on universal process connections, it eliminates the need for numerous, unique instrument configurations for use on different applications. It also allows for easy replacement of products within the facility, regardless of the instrument supplier.

Conclusion

Food and beverage facility operators are faced with numerous challenges when operating processes to meet strict regulatory requirements while producing safe products with consistent quality. They must also optimize facility output to meet consumer demand.

Reliable pressure measurement is critical to allowing facility operators to successfully meet these challenges. Solutions such as condensation-resistant pressure sensors and universal process connections address leading pressure measurement issues, providing more uptime and increased throughput.

Ehren Kiker is product marketing manager for pressure and temperature products at Endress+Hauser. He has more than 20 years of automation experience focusing on process measurement instrumentation.