Temperature measurement accuracy guidelines

Some processes do not require a high level of temperature measurement accuracy, and others do. When considering technology for a given application, it is important to understand the accuracy requirement. This article identifies problems that result from inaccurate measurements and outlines effective and economical strategies for ensuring temperature measurement accuracy.

Temperature measurements can be categorized into three groups:

- Those that do not require accuracy. You simply need to know if the temperature is stable or going up or going down.

- Those that do require accuracy. Strategies in this article will help with those measurements.

- Those where there is uncertainty about the accuracy requirement. If the measurements in this category are on a Preventive Maintenance schedule for calibration or verification, steps may be taken to improve accuracy. The same steps taken to achieve higher accuracy also result in reduced drift, and that would have a positive impact on maintenance frequency.

Improving accuracy and reducing measurement drift are often related and can have measurable results. This article shows how to:

- Select the best sensor for the application

- Reduce errors caused by external environment

- Reduce errors caused by lead wires

- Reduce measurement errors

Sensors and accuracy

There are times when the temperature sensor is selected based on convenience, i.e., aligning with the shelf or the "plant standard." It is not uncommon to see a Type J or K thermocouple measuring a temperature that should be measured with a Platinum Resistance Temperature Detector (RTD). ASTM and IEC temperature standards provide us with sensor measurement uncertainty. With a sample temperature of 500 F (260 C), the uncertainty of a standard grade J or K thermocouple is +/-4 F (+/-2.2 C), while a Class A 100Ω Pt RTD has an uncertainty of +/-1.2 F (+/-0.67 C).

Many process engineers and technicians prefer RTDs. Selecting the best sensor for the application greatly affects the accuracy of the measurement, and an RTD is the most accurate sensor to use when the process temperature is within its measuring range. But you will need to use less accurate thermocouples when you need to measure temperatures that are hotter than the RTD’s upper measuring limits. In these instances you will want to take specific steps with thermocouples to improve the accuracy of the measurement results.

You can improve thermocouple accuracy by using thermocouples constructed with Special Tolerance (also called Premium Grade) wire. The reduced error is achieved by using wire with higher purity alloys. At 500 F (260 C), the uncertainty of a Special Tolerance thermocouple is about +/-2.0 F (1.1 C).

Sensor selection is very important to measurement accuracy. As stated above, a Class A Pt RTD uncertainty is about +/-1.2 F (+/-0.67 C) at the same operating temperature. To simplify the process of choosing a sensor, you can operate from the assumption that changing from a Standard Grade thermocouple to a Premium Grade thermocouple cuts the error rate in half; changing from a Premium Grade thermocouple to a Class A RTD cuts the error in half again.

The role of thermocouple extension wire in measurement accuracy

Thermocouples wired back to a programmable logic controller (PLC) or distributed control system (DCS) must use thermocouple extension wire. Unfortunately the extension wire is yet another source of measurement error. Using standard grade J or K extension wire also adds another +/-4 F (+/-2.2 C) error. You can cut the error rate by using premium-grade extension wire, which has half the error rate of standard extension wire, just as with premium thermocouples. (These error figures are only true when the wire is new and "pure.") Over time the error gets worse as the wire gets contaminated from the atmosphere in your plant and the wire is exposed to temperatures greater than or lower than the wire tolerances. There are many instances where contamination causes even more "drift" than the original uncertainty of new thermocouple wire.

If the uncertainty caused by thermocouples was a fixed offset, it could simply be resolved via calibration. But when the error is in the form of drift that changes over time, calibration becomes a preventive maintenance program that few want to take on. Most plants prefer to avoid that extra labor whenever possible.

What is the most effective way to solve this problem? Start by determining how much error is caused by the thermocouple extension wire. Most people overlook this option until plant operations declare there is a problem or a catastrophic measurement failure occurs. It is understood that thermocouples fail, but it is easy to forget that thermocouple extension wire also fails. When it does, it has to be replaced. If an extension wire is replaced with new extension wire, it only serves to perpetuate the same problems by reintroducing the error and drift it causes. Thermocouples may be a necessary component of an application, but the failures associated with thermocouple extension wire are not — there are alternatives.

Two options for replacing thermocouple extension wire are temperature transmitters and remote I/O hardware. Both use copper wire to transport their signals back to the control system. Unlike thermocouple extension wire, copper can be expected to last the life of the plant. Modern remote I/O products have performance characteristics similar to transmitters and can save a lot of money. Short sections of extension wire may be required when using these transmitters or I/O products. However, special grade thermocouple wire can be employed instead of standard extension wire to minimize the occurrence of errors.

READ ALSO: 6 Ways Temperature Affects LVDT Linear Position Sensors

Compensating for RTD lead wire inaccuracies

Moore Industries TDZ3 Temperature Transmitter

Copper wire is used for RTD lead wires. In three-wire RTDs, the lead wire is called the compensating lead. Copper wire can cause significant error in an RTD measurement because RTDs are resistors, and copper wire is resistance. There are many contaminants in a typical process plant that cause corrosion and this corrosion changes the resistance of the copper lead wires. This resistance change in the lead wire can cause error. To eliminate lead wire error, the solution is to use four-wire RTDs. Here is why:

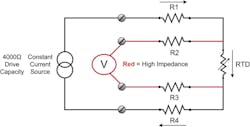

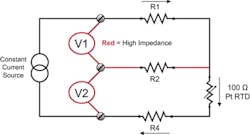

When a third lead wire is added to the RTD, the measurement is made with today’s electronics by taking two voltage measurements (as shown, V1 and V2, Figure 2). The important thing to remember is that these are high impedance voltage measurements. For all practical purposes, there is no current flow through that third lead; thus R3 never enters into the equation.

V1 gives the value of the lead wire resistance R1. V2 gives the value of the RTD + R4 lead resistance. We subtract V1 from V2 and as long as the lead resistances R1 = R4, only the value of the RTD remains. This is an accurate measurement.

It is important to understand that many things work against making R1 and R4 identical when accuracy is the primary concern. Wire gauge intolerance and work hardening varies the resistance. Even if no human error takes place during installation, corrosion constantly works against the measurement and is the main reason R1 never equals R4. So what happens if the lead’s resistances are not equal?

If the resistance imbalance is as little as 1 ohm, a 100Ω PT RTD has an error of about +/-4.7 F (+/-2.6 C). If the aim is to achieve a +/-1 F measurement accuracy, corrosion may impede success, and no amount of calibration will help. However, a four-wire RTD may provide a solution (Figure 3).

Figure 3. Three-wire RTD diagram

Remember, the voltage measurement is high impedance so, for all practical purposes, there is no current flow thru R2 and R3 and no voltage drop. The voltage is only measured across the RTD. R1 and R4 are never measured, thus they cannot create a differential resistance and an error. When using four-wire RTDs, for all practical purposes, there is no error caused by the lead wire.

Four-wire RTDs can have a lead wire of any length and the leads can undergo constant resistance change and still cause no measurement error. It is still important to ensure total resistance does not exceed the drive capacity of the constant current source. Typically modern day temperature transmitters offer enough current drive to support RTD circuits that have up to 3-4K ohms of total resistance. With lead wire error eliminated, it is possible to focus on the sensor and measuring device to further reduce error. The only reasonable objection to using the four-wire RTD is that the existing legacy input card only accepts three-wire RTDs. This is old technology and should be considered for replacement.

Consider another option if, for whatever reason, a 4-wire RTD is not an option; switch from 100Ω RTDs to 1000Ω PT RTDs. As stated earlier in this article, 1Ω of resistance imbalance in the current-carrying legs produces about +/-4.7 F (+/-2.6 C) error. If you change to a 1000Ω sensor that same 1Ω of imbalance will have one-tenth of the affect. The 1Ω of imbalance error drops to about +/-0.47 F (+/-0.26 C).

While the use of the 1000Ω three-wire RTD is a big improvement over the use of a 100Ω three-wire RTD, it is not a panacea. When the lead wire resistance imbalance changes it causes the measurement accuracy to change. That means a calibration program is still needed to temporarily eliminate the error. The four-wire RTD is still the single best solution because it removes all lead wire error and eliminates the need to calibrate due to the inevitable corrosion.

Plant noise

VFDs, motors and radios create "normal" levels of EMI and RFI, which can cause errors in temperature measurements. Thermocouple and RTD signals are very low level mV signals. It does not take much noise to cause significant distortion of the measurements. When wiring these low level signals back to the control system, it is important to use best practices to keep noise away from signal wires. These best practices include, but are not limited to, drain wires, proper grounding, and physical separation.

A better solution is to convert the low level signals to high level signals as close to the temperature sensor as possible. The same amount of noise will affect high signals less than low level signals. Signals like 4-20mA, HART or RS-485 survive most typical levels of noise.

The temperature measurement device and remote I/O

Modern temperature transmitters and temperature I/O systems from major instrument companies have similar performance specifications. When trying to differentiate technology, compare the following specifications:

- The greater the input resolution the measuring circuit can detect, the smaller the changes in the sensor’s temperature can be detected

- Long-term drift spec is a measure of the transmitter’s opimum stability

- RTD excitation current should be low to minimize the self-heating error

- Seek the highest Input Impedance possible so that the measuring device does not draw current

Advanced diagnostics help to predict failures If you are pursuing the very highest accuracy, the final "as built" error in the RTD must be considered. The transmitter can be used to calibrate out that final offset error and match to the ideal curve. Such a process delivers a typical transmitter and sensor combined accuracy of less than 0.05 percent of span.

Putting a temperature transmitter or remote I/O near the sensor digitizes the temperature measurement. This creates two more errors if the signal is sent back to the control or data acquisition system using 4-20mA:

- D/A error occurs when creating the 4-20mA; and

- At the control system, an A/D error occurs when turning the signal back to digital.

- Using the HART digital signal is one way to avoid the conversion errors. MODBUS Serial or MODBUS over Ethernet is another option to keep the measured value digital.

Moore Industries TCM Remote I/O

In summary, using transmitters and remote I/O helps:

- Eliminate errors from thermocouple extension wire;

- Avoid errors caused by noise; and

- Keep signal digital and avoid analog conversion errors

Modern remote I/O instrumentation is often preferred to direct wiring temperature sensors back to the DCS or PLC, as it will actually save money on instrumentation and wiring in the long term. Also, modern remote I/O instrumentation also provides the same accuracy, ambient temperature specifications, and sometimes similar hazardous area certifications as you would find on temperature transmitters at a fraction of the cost. The remote I/O digitizes all the temperatures and delivers them as 32-bit floats to the DCS MODBUS port using a choice of physical layers. Remote I/O also eliminates thermocouple extension wire and all the associated drift, errors and replacement costs.

Practical steps to improve your measurements

The following summary list provides a few practical steps to improve temperature measurement accuracy. Remember that these steps also improve the stability of a measurement, thus minimizing calibration expense.

- Four-wire RTDs eliminate the errors caused by the copper lead wire.

- Always use Class A RTDs that have been aged through temperature cycling — the difference in cost is insignificant.

- Use premium-grade thermocouples and premium-grade extension wire if the temperature to be measured requires the use of thermocouples.

- Be sure to use noise protection installation techniques whenever you have long extension wire runs.

- Mount transmitters or remote I/O as close to the sensors as possible in order to get rid of long thermocouple extension wire runs, which are an error source, have a finite life, and are expensive to replace.

- Get rid of the final RTD offset error by bath calibrating.

- Buy the highest accuracy and highest stability transmitter or I/O you can afford.

- Once you have spent all that money to get your signal digital, keep it digital so there are no more errors introduced.

EDITOR’S NOTE: A previous version of this post mistakenly reversed Figure 2 and Figure 3. The figures have been corrected to display correctly. We apologize for the error.

Gary Prentice is the national sales manager for Moore Industries. He has 36 years of experience working in the process control industry and has been a regional sales manager at Moore Industries since 1993. He graduated with a degree in electrical engineering from Lafayette College in Pennsylvania. Prentice can be reached at [email protected] or 818-894-7111.