IIoT: The future of predictive maintenance

Formally known as Jones Lang LaSalle, JLL is a professional services firm that provides commercial real estate services and integrated facility management solutions to global clients. With origins dating back to 1783, the company employs more than 78,000 employees and has 300 corporate offices in more than 80 countries.

JLL serves large life sciences clients for whom it is responsible for maintaining the critical equipment (or assets) related to research and development and manufacturing. A critical category of machines at pharmaceutical manufacturing or research and development sites is the heating, ventilation and air conditioning (HVAC) equipment. These include chillers, air handler units, (AHUs) pumps and air compressors. JLL has contractual commitments to maintain service levels around availability of these machines and ensure clients do not experience unplanned downtime.

JLL was asked to evaluate state-of-the-art predictive technologies to ensure uptime for a large Fortune 500 life sciences client’s HVAC equipment. Machine parameters like temperature, airflow and humidity were monitored and trended in the building’s automation system.

However, JLL relied on a manual walkaround program for measuring and trending vibration, one of the most important parameters to predict HVAC machine health. Data was collected every 60 to 90 days, depending on the criticality of the equipment. Annually, a maximum four to six vibration measurements were obtained per machine.

Challenges

JLL’s walkaround program had several limitations:

- Cumbersome and time-consuming — Many machines are difficult to access — several of them are behind doors and on rooftops. Safety and liability issues are associated with the machines, especially when the equipment is running. As a result, the data collection was inconsistent and infrequent.

- Unplanned downtime from infrequent data collection — Defects that developed in between the walkaround data collection cycles went undetected for long periods of time, so the client continued to experience unplanned downtime and JLL constantly feared unanticipated machine failures.

- No feedback loop — When equipment operators were sent to perform repairs, they did not have access to vibration data. They had to rely on their five senses and judgement, and they could never be sure the problem was actually fixed. The equipment was put back into service and often times, they had to wait 30, 60 or even 90 days before knowing if the repair was effective. Sometimes equipment operators inadvertently introduced new defects while performing a repair, which resulted in additional repairs.

- Hard to staff vibration analysts on each site — Analyzing vibration requires qualified and trained vibration analysts. This skill set is extremely hard to find. Instead of having an analyst on each site, JLL wanted to centrally staff one or two vibration analysts to support multiple sites. In addition, JLL wanted to automate the data analysis process.

To summarize, the walkaround condition monitoring program that JLL followed was an arduous, manual and time-consuming process with room for errors at every step. Further, it did not provide accurate predictions of machine failure and timely feedback about repairs.

Goals

The limitations of the walkaround condition monitoring programs prompted JLL to consider continuous monitoring solutions in the market. The team of reliability and maintenance engineers at JLL set forth the following evaluation criteria:

- Automated data collection

- Continuous monitoring

- Anytime, anywhere access to vibration data

- Quick and easy deployment

- Some level of automated analysis of the vibration data

Solution

After a comprehensive evaluation process, JLL picked an Industrial Internet of Things (IIoT) startup provider based in Silicon Valley to deliver continuous, automated predictive maintenance. The solution included wireless sensors, cloud computing and machine learning analytics.

Sensors — Wireless, battery-powered triaxial vibration sensors were permanently mounted on critical HVAC machines. JLL connected them to the facility’s Wi-Fi network using an iOS app provided by the vendor. The vendor provided a third-party 4G/LTE Wi-Fi cellular gateway for certain locations that did not have Wi-Fi coverage. All in all, the install process was easy and seamless.

Cloud computing — The sensors securely transmitted machine vibration data on a periodic basis to a cloud platform provided by the vendor. The data transfer to the cloud platform was secure, with traffic from the sensors to the cloud and access fully encrypted. JLL personnel accessed and visualized the vibration data of these machines on their browsers and mobile devices.

Machine learning — JLL automated the process of vibration analysis to a certain extent. JLL site reliability engineers were trained on establishing a machine-specific vibration baseline after the first couple of weeks of data collection on the software. The vendor’s software allowed the use of several narrowband and broadband vibration features to establish a multidimensional baseline. The software used machine learning algorithms to calculate a realtime health score of each machine by measuring the extent of deviation of each new measurement from the multidimensional baseline. This health score was trended and visualized in charts.

The project scope involved monitoring all the HVAC equipment at one of JLL’s sites in Redwood City, California. It included all the air handlers, exhaust fans, chillers and compressors.

"The ability to obtain measurements and an automated health score every three hours is a huge transformative leap over a manual data collection and analysis once every 30 to 90 days," noted site reliability engineer Brad Shacter.

Results

JLL got a quick win shortly after it started its new predictive maintenance program.

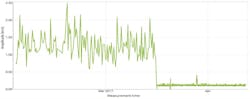

Soon after implementation, an AHU recorded abnormally high vibrations (see Figure 1). On inspection of the vibration spectrum on the vendor’s software, the JLL team observed high amplitudes of vibration on a subsynchronous frequency bin. Further analysis showed that a specific running speed on the variable frequency drive was causing resonance, which resulted in excessive vibration. This was quickly detected by the software, and the JLL staff was alerted. Shacter was able to instantly access vibration data and evaluate corrective measures almost instantaneously.

JLL was able to make an informed maintenance decision with the data and insights provided. Soon, JLL instrumented all AHUs in the facility with sensors to ensure they were monitored continuously.

Conclusion

By eliminating manual, infrequent data collection and replacing it with permanently mounted wireless sensors and machine learning analytics software, JLL moved to cultivating a first-time fix culture or initiative by getting it right the first time.

"We’re getting on-demand predictive maintenance at a disruptive price point," said Sean O’Connor, JLL reliability engineer. "This technology is simplifying Industrial IoT by making use of wireless sensing and machine learning. It is big data without big problems."

Arun Santhebennur is cofounder of Petasense. He brings more than 15 years of experience in building high-tech startups in the enterprise software space. Prior to starting Petasense, Santhebennur co-founded Resolvity, a provider of speech recognition software. He holds engineering and management degrees from IIT and IIM in India.

Petasense offers an end-to-end, easy-to-deploy predictive maintenance system.