How to choose the proper pressure regulator for specific applications

It is essential to the proper management of an industrial fluid system to keep process conditions precise. That includes maintaining proper pressure, which requires choosing the correct industrial pressure regulator for the system.

Selecting the right type of regulator requires an understanding of what is required by the particular application (including system requirements and objectives), what is available and what features should be considered. Here are some general guidelines for common situations.

Analytical instrumentation applications

When choosing regulators for sensitive analytical applications, exact target pressure stability is required to ensure analytical precision.

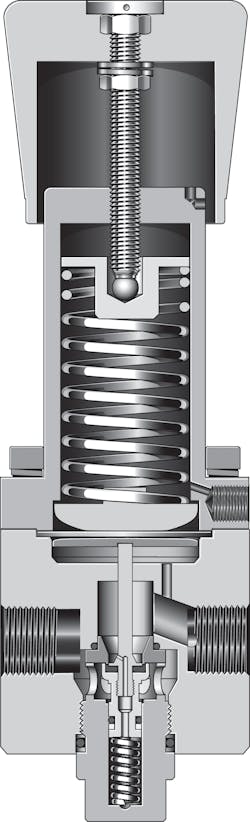

Specialized single- and two-stage spring-loaded analytical and instrumentation regulators provide consistent process outputs with proper pressure control and give users the confidence that their test results are accurate. Typically, these regulators are available in back-pressure and pressure-reducing designs and are easy to adjust, giving end users precise control over pressure levels and the ability to change them quickly as necessary.

More specifically, these regulators should include the following features:

- Poppets designed to resist oscillation caused by system vibration.

- Different sensing mechanism options for a range of pressures. Diaphragm-sensing models perform well in applications with lower outlet pressure requirements, whereas piston-sensing models have higher outlet pressure ranges for applications that demand high-pressure control.

- Large diaphragms to enable accurate low-pressure control.

- Fine-pitched threads on the stem of the control spring to help deliver precise adjustments with low torque.

General industrial process applications

To protect employees, equipment and process output quality, most general industrial processes must have consistent pressure control. And when these applications take place in challenging operational environments, the components used must be able to withstand the associated stresses and strains. That means using high-quality components featuring materials of construction that can withstand the worst exposures imaginable for a particular application.

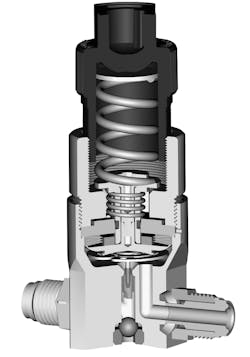

High-quality regulators designed for general industrial process are usually used on larger process lines, meaning they are manufactured in larger diameters. In these instances, it is important that the regulators have the following characteristics:

- Internal seals composed of materials that are compatible with the chemicals and pressures used in your system.

- Regulator bodies composed of corrosion-resistant materials, such as 316L stainless steel, that can improve component longevity in harsh operating environments.

- Availability in dome-loaded, spring-loaded or combination-loaded configurations to suit a specific application. Spring-loaded options can enable precise and easy adjustment, as mentioned earlier. Dome-loaded options, alternatively, are good for applications with a variety of flow variations and may be able to better minimize droop.

High-purity, high-flow applications

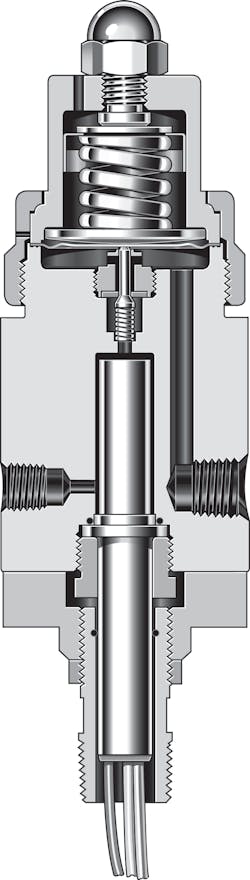

Under some circumstances, such as in semiconductor fabrication, it is necessary for regulators to maintain high levels of cleanliness while handling high flow rates. In these situations, specialized high-purity, high-flow regulators should be used to ensure consistent pressure control.

Choosing the right regulator in these circumstances may revolve around how often you need to adjust pressures. Manual regulators with load springs that interact with pressure-sensing assemblies are adjustable, but other configurations may be preset to a specific pressure or have a dome-loaded design with gas-actuated pressure-sensing assemblies that are more appropriate for specific outlet pressure requirements. When selecting a high-purity, high-flow regulator, the following features should be considered for optimal performance:

- All-welded poppet designs that eliminate the seals’ exposure to atmosphere for clean operation and positive shut-off.

- Self-centering poppets that can help minimize creep and offer leak-tight shut-off.

- Compact designs that allow for close spacing of system components and process lines if space is limited in your high-flow systems. Gas-actuated versions can be less than half the size of conventional diaphragm-operated pressure regulators.

- Finishes and body compositions that minimize the opportunity for contamination.

Sampling sensitive media applications

Sensitive or volatile process gases or fluids require preheating or vaporizing when they are sampled to preserve an accurate representation and eliminate condensation. Under such circumstances, it makes sense to use a vaporizing pressure-reducing regulator.

These regulators are effective because they react well to operator inputs, ambient temperatures and other operating conditions that allow the system to function at peak performance. Vaporizing regulators often include the following features:

- The ability to accommodate sample phase changes.

- Certification for use in critical and hazardous environments, if required.

- Electronic control that can override temperature settings to prevent maximum process fluid temperatures from being exceeded, stopping the regulator from overheating without stopping evaporation.

- Low internal volumes.

Gas distribution system applications

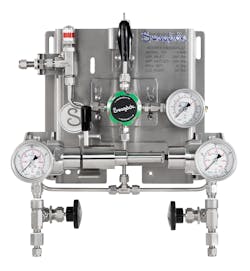

In gas distribution applications, it is important to maintain a continuous gas supply so the system operates without interruption. Under these circumstances, gas cylinder regulators must allow for the automatic switching between two gas sources if one of the cylinders is depleted.

By reducing costly downtime and time-intensive maintenance, these regulators necessarily improve operations and contribute to improving a facility’s bottom line. In addition to being able to transition smoothly from one cylinder to another, gas cylinder regulators should also have the following attributes:

- Metal-to-metal diaphragm seals on all stages that deliver improved material compatibility and leak tightness.

- Designs that require minimal maintenance, allowing users to trust gas distribution systems to work as intended.

- Convoluted, nonperforated diaphragms that provide strength, longevity and improved pressure response.

Hazardous fluid and gas storage applications

When hazardous fluids or gases are being stored, the safety of operators and bystanders is critical. For these situations, specialized tank blanketing regulators are used to maintain the desired pressure of inert gases in a tank’s vapor space. This important function keeps hazardous vapors from escaping by keeping tank pressures safe and consistent.

When selecting a tank blanketing regulator, look for these features:

- Sensitive diaphragm-sensing mechanisms designed for high accuracy in detecting changes in outlet pressure.

- Regulator components such as bodies, seats, poppets and feedback tubes composed of corrosion-resistant alloys, depending on your operating environment.

- Fine-pitched threads on set-pressure springs to provide improved adjustability and resolution when setting or adjusting pressure.

Ready to roll

These general guidelines will help clarify which regulators should be used in specific system applications and in choosing which one is best for particular operational needs. It should be noted, however, that regardless of the application, regulators should always have proper inlet and outlet pressure ratings, temperature ratings, flow capacity, venting and end connections.

If there is still some question about which regulator should be used under specific circumstances, reliable suppliers can advise and support decisions to ensure the proper regulator is selected.

Shaji Arumpanayil is a product manager for Swagelok Company.

About the Author

Shaji Arumpanayil

Product Manager for Swagelok Company

Shaji Arumpanayil is a Product Manager for Swagelok Company.