While there are highly advanced control valves available in the market today, the uses of restriction orifices (RO) in the piping industry is remarkable. Restriction orifice is mainly used to achieve pressure restriction or flow control of the process medium. Based on the service and requirements, RO should be sized for critical or pre-critical condition.

Generally, pressure control RO plates are sized by considering the maximum pressure drop lesser than the critical pressure. And, the flow-controlling RO plates are sized for critical pressure drop. RO sizing is performed per ISO 5167-2, and the thickness of the plate is calculated per the R.W. Miller handbook.

Types of restriction orifice

The RO should be selected based on the required pressure drop and flow rate. The following describes the types of RO.

Single-stage RO plate

A single-stage restriction orifice usually looks much similar to the square-edge orifice plates. Normally, the 45-degree bevel proving on the measuring orifice plate should not be on the restriction orifice plates. But generally, many manufacturers are sizing the restriction orifice plate based on the standard ISO 5167. Since the discharge coefficient values and permanent pressure loss are considered from the standard, the bevel and surface finish should be followed to maintain the uncertainty of downstream pressure.

Otherwise, the flow pattern gets disturbed by the downstream edge of the orifice. And this may deviate the actual downstream pressure from the predicted one.

Multi-hole RO plate

A single-stage multi-hole restriction orifice plate is used where the cavitation is generated, while reducing the pressure in the pipeline. Multi-bore will suppress the cavitation effect and noise generation. Total flow will be distributed and pass through multiple holes, which improves the incipient cavitation factor and reduces the overall noise across the RO.

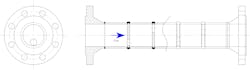

Multistage RO assembly

Multistage RO (MSRO) are used when the required pressure reduction ratio is very high and cannot be achieved by a single-stage orifice plate. Thus, a multistage device essentially consists of a number of single-stage devices built in a single spool. Like a single-stage device, it can be a single-hole multistage design or multi-hole multistage design or a combination of both. In single-hole MSRO, eccentric-type orifice plates are generally used and are installed diametrically opposite each other. The minimum distance between each stage is equal to the internal diameter of the pipe.

Multi-hole multistage RO assembly

Multi-hole multistage restriction orifices are used for higher pressure drop and where noise needs to be controlled.

Critical orifice plate

This is used to restrict flow by keeping the upstream pressure constant. This RO is sized for choked flow conditions. Generally, the thickness of the RO should be considered higher than the normal RO plates.

Factors for sizing RO

The following factors should be considered when sizing RO.

Pressure drop

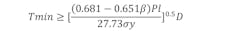

Required pressure drop is a critical factor for sizing and selecting the RO model. Also, the minimum required thickness of RO depends on the pressure drop across it.

Where:

Tmin is minimum required plate thickness

β is beta ratio

Pl is maximum differential pressure across RO

D is pipe ID

σy is yield strength of plate material

Flow rate

Because the pressure drop varies when the flow rate changes, the RO should be sized at normal flow rate. For critical RO, it should be designed for the required downstream flow rate.

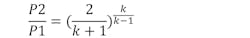

Sonic flow

When a gas accelerates through a restriction, its density decreases and its velocity increases. Since the mass flow per unit area is a function of both density and velocity, a critical area exists at which the mass flux is at a maximum. In this area, the velocity is sonic, and further decreasing the downstream pressure will not increase the mass flow. This is referred to as choked or sonic flow condition.

Where:

P1 is upstream pressure

P2 is downstream pressure

k is Cp/Cv (isentropic exponent)

Cavitation

Cavitation occurs frequently in liquid flow restrictions where a large pressure drop exists. When the downstream pressure is below the vaporization pressure, vapor bubbles are created, called cavitation.

When the liquid has passed through the restriction orifice plate, the velocity decreases, and the pressure increases. This leads to the collapse of the vapor bubbles, and flashing can occur.

RO should be sized to maintain the cavitation index less than the incipient cavitation index of the RO plate.

Where:

Xf is cavitation index

P1 is upstream pressure

Pt is pressure at vena contracta

Pv is vapor pressure of fluid

Noise level

Predicting noise level in RO requires two stages. First, determine the estimation of the sound power generated in the fluid due to pressure reduction/cavitation/sonic condition.

Second, the transmission loss through the pipe must be subtracted to determine the sound level at a predetermined location outside the piping. The noise prediction for RO plates must be calculated according to IEC 60534-8-3 or IEC 60534-8-4.

Compared to the flow-measuring orifice and due to the high pressure drop, the sizing of RO is more critical, and there are many parameters to consider.

Pressure-controlling application

The restriction orifice plate is mostly applied in noncritical flow limitation, and it is used in pipelines where a known/fixed pressure drop is required. Also, it could be, for instance, after a control valve to divide the required pressure loss into two elements. Based on the flow rate, upstream pressure and required pressure drop, the RO should be sized up to the sonic condition or where cavitation occurs. For reducing gas pressure with the required inlet flow rate, the maximum pressure loss is limited to the critical pressure drop where the sonic condition occurs. For liquid service, the RO should be sized to avoid cavitation.

Flow-controlling application

For liquid service, if the pressure in vena contracta decreases to the vaporization pressure of the liquid, a cavitation zone is created. This cavitation zone will act as a flow limitation.

Sizing to avoid sonic flow

Sonic flow is a major factor in sizing RO for gas service. When the required pressure drop is higher than the critical pressure drop, sonic flow may occur, and the choking would take place. Sonic flow in the pipeline will create noise and vibration in the pipeline, and due to the vibration, the chances of mechanical failure will increase.

To avoid this, the maximum pressure drop across a single-stage RO plate should be limited to critical pressure drop.

Sizing to avoid cavitation

For high vapor pressure liquid service, the sizing of RO is stringent to avoid cavitation and its consequences. Cavitation and subsequent flashing may erode the downstream pipe, causing catastrophic failure in the pipeline. Also, the vibration and noise issues will occur due to cavitation.

To avoid this, the sizing of RO could be limited to the cavitation index within the incipient cavitation of RO. Inlet pressure, outlet pressure and vapor pressure are the dependent factors for cavitation index, and the incipient cavitation factor will be dependent on the beta ratio of the plate.

Sizing to reduce noise

The wrong sizing of RO can create noise in the plant. Reduction of RO noise can be achieved by either source control (preventing the noise generation) or path control (pipe insulation, silencers or increasing pipe schedule). Source control is a more effective method, thus preferable. Sound, once generated, propagates virtually unattenuated in the downstream pipe. High sound levels inside piping systems can damage the pipe and mechanical components located downstream by inducing excessive vibration. To control the noise over RO, the following options can be selected when sizing.

- Reduce the pressure drop.

- Increase the stages of reduction.

- Use multi-hole RO plates.

- Optimize the pressure drop across each stage.

- Increase the margin between the cavitation index and incipient cavitation index.

Vaisak Prabhakaran is a senior design engineer at Hydropneumatics in Goa, India. He specializes in the designing of flow elements. Prabhakaran heads the engineering department for offering, sizing and designing flow elements. He is a graduate of mechanical engineering and has a master’s in project management. He also offers consultancy for flow measurement, line pressure/flow control services and selection of meters. Prabhakaran has headed the development of multiple new types of flow elements by working with leading flow laboratories in India.

Vaisak Prabhakara

Vaisak Prabhakaran is a senior design engineer at Hydropneumatics in Goa, India. He specializes in the designing of flow elements. Prabhakaran heads the engineering department for offering, sizing and designing flow elements. He is a graduate of mechanical engineering and has a master’s in project management. He also offers consultancy for flow measurement, line pressure/flow control services and selection of meters. Prabhakaran has headed the development of multiple new types of flow elements by working with leading flow laboratories in India.