Pump systems are elemental components in process engineering systems and ensure the smooth operation of cooling systems, metering and filling equipment or pumping lines. Because of this, availability, reliability and long life have the highest priority. An intelligent, digitally networked design for Industry 4.0 enables continuous condition monitoring and predictive maintenance. This increases flexibility, process reliability and system availability.

In the course of progressive digitalization of industrial production, the pump industry is therefore moving away from central control toward decentralized intelligence, which controls processes autonomously, identifies faults and remedies problems automatically. For example, if there is a fault with the pumps in a self-monitoring production plant, this is identified and, if possible, remedied automatically. If this is not possible, the fault is reported to the central control system and, for example, a networked replacement pump drive in a bypass route is switched on.Intelligent drives equipped for the digital future

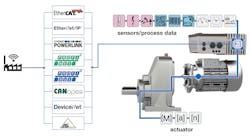

But how does the pump get its intelligence? Fully matched drive systems — consisting of the gear unit, motor and frequency inverter — can be tailored to the particular requirements of the operator’s application. They can be networked and operate autonomously; their performance is scalable. The decentralized drive systems form master-slave groups, which intelligently communicate with each other so that they can autonomously monitor and control the entire pump system. The frequency inverter is installed directly on the motor. Because of this, the drives can be easily integrated into the operator’s plant topology without the need for major changes. Furthermore, decentralized integration offers further benefits: Investments for control cabinet installations and extensive wiring are eliminated, and in case of damage, quick and easy replacement of the pump drive is ensured.

PLC carries out control functions independently

The frequency inverter is the "brain" of the drive. It can be equipped with a programmable logic controller (PLC) that autonomously performs control functions and reduces the load on the high-level plant control system. Among other things, the frequency inverter adapts the pressure and flow rate of the pumped liquids to the actual requirements. Therefore, no additional energy is wasted on valves and flaps. The frequency inverter perfectly adapts the power to what is required, regardless of whether a fixed set point has been set or whether the adjustment is made manually.

Different drive powers are dependent on the pump application. Pumps used to supply cooling and process water must primarily ensure an uninterrupted flow — throughput or flow mode. This requires a highly stable drive speed. On the other hand, pumps for filling or metering liquids — filling or batch mode — require maximum positioning precision. For example, the NORDAC FLEX frequency inverter is especially suited for pump applications. It provides powers of up to 22 kW and has a range of accessories to easily adapt to subsequently changed situations. Due to the exchangeable memory in the form of an EEPROM, which contains the parameter set and the PLC program, the PLC settings can be transferred by exchanging it from one inverter to another. It also has the necessary interfaces for integration into the operator’s automation solution. In addition to digital interfaces, it provides the option of analog processing and can therefore evaluate the operator’s flow sensors and batch sensors. It also has high protection classes up to IP66.

Globally available drive and pump data

Through integration of the PLC into the frequency inverter, drives can record the drive and pump data, e.g., flow rate, pressure, pressure difference and temperature, evaluate all of the available sensor and actuator data, provide optimized diagnostic facilities and communicate the data to the higher level control system via the bus system. From there, the path can continue into a cloud, as intelligent drives are equipped with the necessary interfaces. In addition, drive specialists can support operators with the setup of their own secure cloud solution. Only measurements that have changed are sent to the cloud. This considerably reduces the data volume and network load. The path to the cloud can also be decoupled from the central system control, which increases data security for the operator, as only the drive data are read. In the cloud, data can be made available for evaluation and analysis from anywhere in the world. The entire pump system with NORD drives can therefore be monitored. With a mobile terminal device, system users can access this data from anywhere and can obtain all of the important information about the condition of the drives in a clear visualization.

Through continuous monitoring of the field level, linking of communication, sensors (temperature and current consumption), process data (torque, acceleration and speed) and the vital parameters of the drive, drive systems can implement condition monitoring. This forms the basis for condition-oriented maintenance. Together with the operator, drive specialists can also develop predictive maintenance solutions for predictable and therefore plannable maintenance of the pump drive units. The objective of these algorithms is to reduce unscheduled downtimes, lower service and maintenance costs and to increase the service life of the drives and pumps.

Jörg Niermann is a marketing manager at NORD DRIVESYSTEMS in Bargteheide, Germany.