How pumping system design affects sealing performance

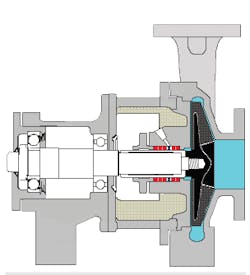

Understanding how different types of pump designs impact sealing is critical to optimizing the efficiency, safety and longevity of the sealing system. Used for a wide variety of media, including clear fluids, solutions and slurries, single-stage centrifugal pumps are one of the most common types (Figure 1). Fluid drawn into these pumps enters the eye of an impeller that spins it to the outside of its container, or volute, building pressure as it moves toward discharge. Some of this fluid will work its way behind the impeller, where it must be sealed with compression packing or a mechanical seal.

The pressure in the stuffing box containing the packing can be estimated by the following equation:

SBP = [Discharge – Suction] / 3 + Suction

Pressure at the bottom of the stuffing box will be higher than the suction pressure, but considerably lower than the discharge pressure. It should be noted this calculation will yield a conservative estimate of stuffing box pressure that can be further reduced by pump design.

A hole in the stuffing box serves as a port for injecting clean fluid that circulates around a lantern ring aligned under the flush port. The fluid flushes solids back into the process to protect the packing from abrasive wear. If the clean fluid is injected at a pressure exceeding that at the bottom of the stuffing box, some of it will leak back into the process and some will leak out to the atmosphere. Recommended flush injection pressure is 15–30 PSI (1–2 Bar) greater than the pressure at the bottom of the stuffing box.

Fluid injection is also used to lubricate and cool dry-running packing that is subject to frictional heat and to prevent air from entering the pump, which reduces flow and operating efficiency.

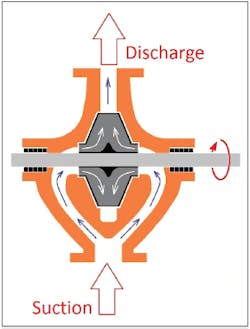

Centrifugal pumps utilize three types of impellers—open, semi-open and closed (Figures 2, 3 & 4). Open designs prevent fluids with large solids from clogging the impellers, but at the expense of pump efficiency. Backing plates on semi-open designs serve to trap the fluid for more efficient operation. Closed impellers are for use with clean fluids, since solids could accumulate in the eye, which would require tearing down the pump to remove them.

Single-stage centrifugal pumps

Single-stage centrifugal pumps typically have good bearing support of the shaft with few run-out or "whip" problems. However, in some cases they are subject to cavitation. This occurs in the eye of the impeller, where the fluid is under vacuum. If the pressure is low enough, it will cause the material to vaporize, forming air or water vapor bubbles. As the fluid passes through the pump under increasing pressure, these bubbles implode, sending shock and vibration through the impeller, adversely affecting the seal. This phenomenon can be mitigated by running the pump at slower speed and higher pressure at the suction end to prevent air from entering the fluid.

Double-ended split-case pumps

Operating on the same centrifugal principle, but slightly different geometry, are double-ended split-case pumps (Figure 5). Fluid enters both ends of the pump and is directed into the eye of an impeller, which spins it out of the volute to discharge. Packing is installed on both the shaft and bearing ends, so the stuffing box is exposed only to suction pressure, which is usually quite low.

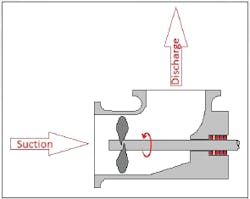

Axial flow pumps

Axial flow pumps operate like hydro turbines in reverse, whereby a propeller (or axial impeller) pushes the fluid to discharge (Figure 6). Since the stuffing box is located downstream of the propeller at the discharge end of the pump, the packing is exposed to the full discharge pressure.

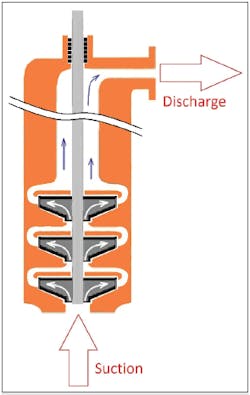

Vertical pumps

Vertical turbine pumps are typically flange-mounted on a floor, extending downward into a water-filled sump hole (Figure 7). Available as single- or multi-stage pumps, they feature an impeller or series of impellers rotated simultaneously by a single shaft. The impellers increase the pressure of the upward flow, subjecting the stuffing box to full discharge pressure.

Vertical pumps can be quite long, so inadequate bearing support can cause the shaft to run out. This can induce undesirable lateral motion on the packing. Worse, the packing may be forced to serve both as a bearing and a seal. To withstand these conditions, the packing should be resilient, elastic and resistant to deformation. These properties rule out packing such as graphite foil in favor of fiber-based materials.

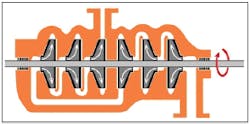

Multi-stage pumps

Multi-stage pumps are used for high-pressure applications such as feeding the boilers in steam-powered generating plants. Stuffing box pressure can vary with pump design and number of stages. Designed for clean fluids and high operating speeds, these pumps typically have high- and low-pressure ends with a hydraulic pressure equalization line running between the stuffing boxes.

Like vertical pumps, multi-stage pumps feature a series of impellers to build fluid discharge pressure. In the case of the six-stage pump pictured in Figure 8, fluid enters at the drive end, where a stuffing box is exposed to suction pressure. Channeled from one impeller to the next through the pump casting, the fluid can reach extremely high pressures at discharge.

A second stuffing box located at the bearing end is exposed to an intermediate pressure from the third impeller. This pressure is greater than the suction pressure, but much less than the discharge pressure, which can reach 2,000 PSI.

Fortunately, the stuffing boxes in these pumps are not exposed to discharge pressures and typically see below 500 PSI, which is within the range of some packing materials.

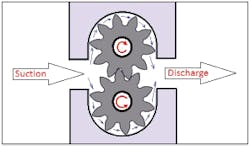

Gear pumps

Positive-displacement or gear pumps operate on a different principle than centrifugal pumps. In external gear pumps the fluid flows around the outside of the gears, the intermeshing of which forces it through the pump to discharge (Figure 9). This design makes these pumps particularly suitable for use with highly viscous fluids such as resins, emulsions, syrups and adhesives. As such, they are used for transfer or metering applications.

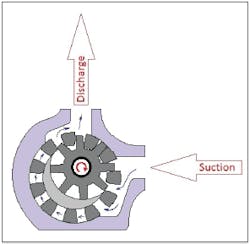

It should be noted gear pumps will continue to displace fluid as long as their shafts are turning, which can pose a problem if a clog occurs at the discharge. The resulting buildup of pressure can blow out seals and damage the pump. Therefore, most gear pumps have pressure relief valves to divert fluid back to the suction side for recirculation through the pump. Internal gear pumps operate slightly differently, but also have pressure relief valves to prevent damage from excessive pressure (Figure 10). In both external and internal gear pumps, the maximum stuffing box pressure is determined by these valves.

Other rotating equipment includes mixers/agitators, which are similar to pumps in terms of the speeds to which the packing is exposed. There are basically three types of mixers/agitators, top-, bottom- and side-entry. Top-entry models are subject to the same concerns about shaft run-out, "whip" and lateral forces on the paddles that are encountered in some vertical pumps. Although some fluid may splash onto the packing, these mixers basically run dry, so the packing must have the ability to dissipate the resulting frictional heat.

In bottom-entry mixers, the packing is always exposed to fluid and may also be exposed to solids, requiring abrasion-resistance. If the seal fails, the entire contents of the tank will eventually drain out onto the bearings, the floor, and other components under the stuffing box.

The packing in side-entry mixers may be fully or intermittently exposed to fluid, as well as side loading and vibration.

Aside from media, temperature, speed, and other application variables, the configurations and operating principles of rotary-type pumps exert different forces on the seals used to keep them from leaking. These forces can spell the difference between acceptable seal performance and failure. Understanding these differences has important implications that should be taken into account to assure proper sealing selection for long-term, trouble-free performance.

Chris Boss is a senior applications engineer for Garlock Sealing Technologies in Palmyra, NY. He has held various positions in production engineering, product development, and applications engineering for the company’s compression packing division. He is a BSME graduate of the State University of New York at Buffalo. Mr. Boss can be reached at 800-448-6688 or [email protected].