Dos and donts of seal validation

When designing and developing equipment that utilizes sealing systems, confirming the sealing system performance is an important part of the validation process for the equipment. Sealing system performance in many cases can be directly linked to overall equipment performance, such as seal leakage to hydraulic cylinder life, and seal friction to hydraulic motor position control. The factors influencing sealing functions are many and diverse in their impact on each sealing application.

Improperly balancing resources to address potentially significant factors involving the performance of the sealing system can lead to decisions in the validation process that produce erroneous or misleading results, or consume excessive resources.

The following two-part article reviews the sealing system validation process and provides suggestions for best methods to properly address validation of sealing systems for various applications. Part I of this article will cover the Validation Process Flow and DO”s and DON’Ts in the areas of Pressure, Load, Speed, Dynamics, and Temperature. Part II, which will appear in the October issue of Flow Control, will further explain how to use the Process Flow effectively, cover DO”s and DON’Ts in the areas of Time, Assembly, Media, Process, Design, and Materials, and discuss what happens when a "DON’T" is done.

Considering Validation

Validation is a crucial part of the system design process. It is required in order to ensure the system performs as desired, possesses the reliability expected, and provides the confidence that the performance and reliability will both be maintained over the life of the process. Beyond that, manufacturers want to:

• Limit the cost of validation

• Understand the risks or liability associated with the process

• Understand the risk associated with performance guarantees

• Understand what influence various factors have on the system’s performance

In order to validate systems properly, substantial upfront planning is required. Errors in the planning stage often cause improperly validated systems, which can lead down two paths, neither of which is desirable: 1) Redevelop or 2) Launch a product with poorly understood behavior.

In many operations, the sealing system is a critical part of the process and its performance directly relates to overall system performance. For example, seal leakage affects cylinder or actuator life, and sealing system friction can affect position control. Since sealing system and process performance are related, the validation of the sealing system performance is a critical part of the process validation exercise.

Validation Is a Process

Validation is not just a series of tests; it is a process. It starts off with the flagging that validation is required and then moves onto identifications of items of concern, continues through the testing, and finishes with analysis and confirmation of results. Unfortunately, market forces and conditions do not permit all of possible uses to be considered during validation of a design or development. Decisions have to be made to balance the:

• Risk: Risk of failure mode or system functionality loss and associated liability

• Investment: Effort required to properly validate the product

• Reward: Value of knowing system performance

In situations where time and cost associated with validation are limited, proper considerations for the seal function in the equipment allow smart businesses to maximize return on investment and minimize risk associated with a selected validation plan.

Process Flow

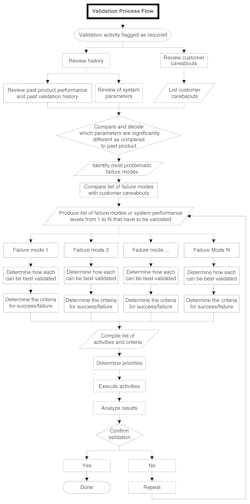

The chart and table immediately below break down the validation process flow.

“DO”s" & "DON”Ts" of a Validation Plan It is important that all significant factors be taken into consideration when working through the validation process flow. While the number of critical elements to consider for a sealing system may seem daunting, there is general practical experience with many of these factors that can provide some assistance to avoid common mistakes and replicate common successes. Some of these practical experiences, referred to here as "DO”s" and "DON’Ts" (see tables above and below), are more applicable than others, so each individual application will determine which ones are appropriate.

As detailed here, validation is a process that contains a number of steps. Paramount to success is effective communication between the sealing supplier and the customer, and subsequent thoughtful and planned action. While this approach does require more effort up front, the reward is significantly less risk of negative results or consequences later. As shown in the variety of DO”s and DON’Ts discussed, taking into account the critical elements of seals and bearings prior to the testing phase of the validation process can help optimize the return on investment. The end result of this approach is ultimately a happier set of parties through better overall performance of the process. In part-two of this article in the October 2011 issue of Flow Control, we will further explain how to use the Process Flow effectively, cover DO”s and DON’Ts in the areas of Time, Assembly, Media, Process, Design, and Materials, and discuss what happens when a "DON’T" is done.

Larry Castleman is technical director of Product Development for Trelleborg Sealing Solutions. Mr. Castleman has held a variety of engineering positions related to manufacturing and marketing in 20 years with Trelleborg Sealing Solutions. During that time, he has been involved in all facets of polymer seal and bearing design, including FEA, product validation, surface finish, failure analysis, and troubleshooting. Mr. Castleman can be reached at [email protected].

John McLaughlin is manager of product testing for Trelleborg Sealing Solutions. He has more than 15 years of experience in product testing of polymer base products. During those years, he has had the opportunity to manage and/or play a key role in seal and bearing testing, test method development, final validation, defining root case analysis of failure modes and developing training materials. Mr. McLaughlin can be reached at [email protected].

Mark Sitko is product development engineer for Trelleborg Sealing Solutions. Mr. Sitko has been with Trelleborg Sealing Solutions in a variety of engineering positions for the last 13 years. He has a total of 16 years of experience in the sealing industry. Mr. Sitko”s previously published work includes IFPE 2008”s The Effects of Hydraulic Cylinders Moving Faster, Stronger and Longer on Sealing Systems and SAE 2006-01-0976 Effect on Fuel Permeation Based on Changes in Seal Design. He can be reached at [email protected].