For turbocompressor applications, it is very common to specify dry gas seals instead of wet seals (oil seals). In particular, the tandem dry gas seal arrangement with an intermediate labyrinth is popular.

Figure 1 shows an example of a modern centrifugal compressor. The dry gas seals are shown at both ends of the rotor. The seals are located between the process section and the bearing.

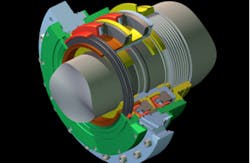

Figure 3 shows a tandem-type dry gas seal with an intermediate labyrinth configuration for a centrifugal compressor application. The tandem seal with intermediate labyrinth purged with nitrogen is also a good fit for turbocompressors. In such a seal arrangement, nitrogen is injected between two seals. This action ensures the gas vented from the secondary seal will be mostly nitrogen during normal operation, since nitrogen supplied between the primary and secondary seals can be differential-pressure controlled to ensure it is higher than the primary seal vent.

The seal panel, the seal piping arrangements, and the seal vent system details are critical for reliability, performance, safety, and operation of dry gas seals in turbocompressor applications. Compressed gas properties and conditions should also be carefully considered when specifying a dry gas seal and designing the seal system. Liquid or dirt should not be allowed in a dry gas seal.

Dry gas seal operational considerations

The function of a gas seal system is to continuously supply clean and dry seal gas to each dry gas seal. Dry gas seal problems are responsible for many shutdowns of turbocompressors.

RELATED: Wet Seal to Dry Seal Conversion–Considering the benefits of retrofitting your compressor

Since clearances between seal faces are usually less than 4–10 microns, the seal gas passing between faces should be clean and dry. While the seal filtration requirement is 1–3 microns, 1-micron filtration systems are typical for dry gas seals.

Small (shallow) grooves on seal faces pump the gas into the area between the stationary face and the rotating face, increasing the pressure between the faces. When this pressure is greater than the static pressure holding the faces together, the faces separate by a very thin layer of gas. Dirt or liquid can damage the seal faces, with the grooves (necessary for seal force separation), in particular, becoming plugged and causing face contact and seal damage.

A minimum shaft speed is required for the operation of dry gas seals. This speed is known as the lift-off speed. Care should be taken for variable-speed turbocompressor operation (particularly steam turbine- and gas turbine-driven compressors) to ensure the operation is always above the specified minimum speed for the dry gas seals. Steam turbine- and gas turbine-driven compressors usually require cool-down operation at low speed after a shutdown and this low speed rotation should be performed with respect to the specified minimum speed for the dry gas seals. Historically, many dry gas seals have been damaged in low-speed operations.

An important section of a dry gas seal is the vent system. Special attention is required for the primary vent system (vent system of primary seal). In the primary vent system, a vent rupture disc is typically installed in parallel with the vent line to rupture at a set pressure and prevent excessive pressure to instruments on a primary seal failure. A pressure-relief valve (PRV) may be installed instead of rupture disc, particularly for large machines.

Saturated gas applications generally require special considerations for seal systems. Usually a cooler, a separator, and a heater are required in addition of other components in the seal gas system for a saturated gas service to assure liquid cannot be delivered or formed in the dry gas seal. A typical requirement for the heater is to reheat the seal gas to more than 20 C (sometime 30 C or 40 C) above the saturation temperature.

The inner labyrinth seal (or process labyrinth seal) plays an important role in the performance and reliability of a turbocompressor and its dry gas seals. The differential pressure across the inner labyrinth seal should be carefully monitored. This differential pressure needs to be maintained at a relatively constant designed value for uninterrupted and stable flow. A low seal gas flow (to process side) may cause migration of dirty process gas into the seal. A high flow may cause the flow coefficient in the system to exceed the designed value, creating detrimental flow turbulence, as well as inefficient performance.

Sometimes the differential pressure is higher than normally designed differential pressure, thus indicating a higher flowrate than designed; as noted it could result in inefficient performance or a malfunction. Often the differential pressure is lower than the designed value, which could be as a result of wear in the inner labyrinth seal.

The separation seal is installed between the compressor bearing and the secondary dry gas seal. The separation gas system function (the barrier seal system function) prevents lubrication oil from entering the dry gas seal. The nitrogen flow into the separation seal should be properly monitored. In many machines, the nitrogen supply system (such as control valves, control setting, etc.) does not receive proper attention, which could eventually result in seal problems and even seal failures. A low flow of nitrogen through the separation seal may allow the bearing lubrication oil to migrate into the seal chamber, causing seal face failure. A low flow of nitrogen is sometimes the product of an inaccurate setting of control valves on the nitrogen seal supply line.

Dry gas seal root cause analysis

The RCA (root-cause analysis) is an important step after a seal failure. After a dry gas seal failure, the seal should be sent to the seal manufacturer’s facility for dismantling and investigation.

Based on experience, heavy contacts between seal faces have been observed in many failed seals. Heavy contacts between outer circumferences are often visible on dismantled seal faces. In this case, rotating faces and stationary faces may have evidence of contact, whether halfway around the circumference or around the entire circumference. These damages could be related to the misalignment of faces in service (the rotating face misalignment).

A well-known reason for dry gas seal failure (or problem) is dirt (such as dust or contamination) or liquid finding its way to the seal — whether through seal gas or from the inside of the compressor. Dust or contamination inside seal components could potentially cause "hang-up" of the static faces, which might show itself as high seal gas flows at the primary vent.

In case of dirt and contaminations in a seal assembly, all parts and components should carefully be investigated to find a clue about where dirt or contamination comes from. A source of dirt is the seal gas itself, for example, because of insufficient or inefficient seal gas filtration. If the seal gas supply line does not appear dirty, but the seal assembly is dirty, this could indicate that the dirt or contamination entered the seal chamber directly from the compressor casing. The reason could be an insufficient seal gas pressure during transient situations, such as the startup.

Large numbers of dry gas seal assemblies have problems because of an issue with an O-ring or a V-ring. There are many sealing elements (O-rings, V-rings, U-rings, etc.) in a seal assembly, which can cause seal operational problems. If an O-ring or a V-ring allows gas to bypass, the gas stream would pass up the primary vent. In many cases, the deterioration of a ring or a sealing element may explain the rise in the primary vent flow, which could be confused with seal face deterioration.

Material selection is critical for sealing elements. The compatibility of sealing element materials with process gas compositions in all operating cases (normal and abnormal) is important. These sealing elements require robust and sound designs to ensure long-term, trouble-free seal operation. Each of these sealing elements (U-ring, O-ring and V-ring) could easily be damaged in a careless installation or overhaul exercise. The deterioration of seal elements (such as different rings) could be due to abrasive wear from dirt or contamination from dirty process gas.

The inspection of the seal can help identify the root-cause of high flow of the primary vent. If the primary seal faces are damaged or deteriorated, it could be deduced that the leakage path is the primary seal itself. Meanwhile, if the primary seal faces are in good condition, it can be determined that high primary vent gas leakage is not caused by damage to the primary seal faces. In such a case, other root-causes and leakage paths should be examined.

Lubrication oil is another important root-cause of seal failures. The first section that will be contaminated by lubrication oil is the barrier seal (the separation seal). For such cases, there will be oil ingress past the barrier seal. The second section that will be contaminated is the secondary seal. If the lubrication oil can pass through barrier seal and contaminate the secondary seal, the secondary seal may fail, leading to problems with the primary seal (oil ingestion and subsequent failure).

Seal system improvements

To eliminate many of the problems noted above, there are some dry gas seal upgrades that can improve the reliability of turbocompressors.

The seal gas filter system: Standard filters are typically small in capacity and large in the mesh size. For dry gas seals, filters should be 2-5 times larger (in terms of capacity), and 3-4 times smaller in mesh size than typical standard models. As noted earlier, it is not uncommon for dry gas seal systems to employ filtration of 1 micron or less.

The operation range of seal system instruments: The instrumentation and control systems for sealing systems vary per application. In some of these applications, instruments or valves might be improperly specified. Sometimes the instrument range is not sufficient, and too often seal system flowmeters are not sized properly.

In a case study for a turbocompressor, the original seal filter meshing was 4 microns. The upgraded seal filter was a filter system with the 1 micron mesh size and the dimensions 2.5 times larger than the original filter.

The oil carryover from the upstream can generally be a problem. Compressors in the upstream — whether oil-flooded screw compressors, oil-lubricated reciprocating compressors, or old-fashioned, oil-sealed turbocompressors — can introduce oil into the gas flow, which usually creates some problems for compressors with dry gas seals in the downstream. Other installations, such as reactors and processing equipment, can contaminate the gas with dirt, dust or liquid in normal or abnormal situations.

Too often, turbocompressor manufacturers are preferred to use "generic" (or manufacturer’s standard) seal panels. Emergency and abnormal operational cases, which can make the seal system more expensive (due to special features), are often neglected. All these situations should be considered during the compressor bidding stage. However, in the rush to order compressors in engineering and procurement phases, these kind of details are often neglected.

The tandem dry-gas-seal is the most common seal in turbocompressors. The intermediate labyrinth purged with nitrogen (to eliminate fugitive emissions) is nearly always recommended. The primary vent is between the two seals and usually connected to the flare system. The flare backpressure is very important, and the seal should not be subjected to a reverse pressure condition (dirty gas could come back form flare system to the seal), as this can cause a premature failure.

Other important dry gas seal system improvements are:

Seal gas booster: A commonly reported root-cause for seal failures has been low pressure of seal gas at startup, which resulted in dirty gas moving to the dry gas seal from the compressor casing. It is recommended to install seal gas boosters to ensure supply of seal gas during standstill and transient conditions, if a reliable source of seal gas with suitable conditions is not available for these transient times (particularly the startup).

"Burst-Alert" for rupture-disk: The "Burst-Alert" for any seal system rupture-disk (in primary vent system) is always a good recommendation to enable integrity checks while the seal system is online. Another suitable recommendation is to replace the rupture-disk (in the primary vent system) with a suitable pressure relief valve (PRV).

Flowmeter on secondary vent: A good recommendation is to consider a flowmeter on the secondary vent. This can give good information regarding the secondary seal health and the overall seal system conditions.

Differential pressure on any seal stage: Another good recommendation is the installation of differential pressure for each seal stage including the primary seal, the secondary seal, and the barrier seal (acting as the tertiary seal). In this way, the differential pressure (and the condition of each seal) can be assessed, verified and compared to results obtained by other instrumentation and monitoring systems.

Additional flowmeters on primary vent for double-check: Additional flowmeters for double-check and verification of the primary vent flow is always a good recommendation.

Amin Almasi is a senior rotating machine consultant in Australia. He is a chartered professional engineer of Engineers Australia (MIEAust CPEng – Mechanical), IMechE (CEng MIMechE) holds bachelor’s and master’s degrees in Mechanical Engineering, and is a registered professional engineer in Queensland. He specializes in rotating machines, including centrifugal, screw, and reciprocating compressors, gas turbines, steam turbines, engines, pumps, subsea, offshore rotating machines, LNG units, condition monitoring, and reliability. Mr. Almasi is an active member of Engineers Australia, IMechE, ASME, and SPE. He has authored more than 100 papers and articles dealing with rotating equipment, condition monitoring, offshore, subsea, and reliability. He can be reached at [email protected].

Amin Almasi

Amin Almasi is a lead mechanical engineer in Australia. He is a chartered professional engineer of Engineers Australia (MIEAust CPEng – Mechanical) and IMechE (CEng MIMechE) in addition to a M.Sc. and B.Sc. in mechanical engineering and RPEQ (Registered Professional Engineer in Queensland). He specializes in mechanical equipment and machineries including centrifugal, screw and reciprocating compressors, gas turbines, steam turbines, engines, pumps, condition monitoring, reliability, as well as fire protection, power generation, water treatment, material handling and others. Almasi is an active member of Engineers Australia, IMechE, ASME and SPE. He has authored more than 150 papers and articles dealing with rotating equipment, condition monitoring, fire protection, power generation, water treatment, material handling and reliability. He can be reached at [email protected].