Cannabidiol (CBD) is one of approximately 100 substances that can be extracted from hemp plants. It is produced similar to the way essential oils, like lavender or eucalyptus, are extracted — by pressing chemical solvents through plants in order to create the reactions needed to unlock the desired molecules.

This process typically uses metering pumps or rotary gear pumps to move chemicals (such as ethanol) through the biomass at specific volumes, pressures and temperatures.

Increased demand for reliable equipment

While botanical extraction applications have been around for decades, CBD oil extraction began in mass with the 2018 passage of the Farm Bill. Many pump manufacturers were not targeting CBD oil extraction applications as recently as 2019, so most of the first-generation extraction skids leveraged prototype or unproven hydraulic equipment. Not surprisingly, extractors experienced reliability issues with early pumping equipment. This created a demand for established pump manufacturers to bring reliable equipment to market, focusing on four key requirements:

- Reliability and simple maintenance: Rotary gear pumps have been proven in the field for decades. The simplicity of the gear pump design requires less maintenance than diaphragm designs or other types of metering pumps.

- Compact footprint: Skid builders serving this market prefer compact pump designs because skid real estate is at a premium, and there is a need for minimizing piping runs.

- Sanitary tri-clamp connections: It is imperative to reduce the amount of hard-to-clean interior crevices and cavities in the pumps and the connections to the piping.

- Economical solution: Pumps sold into this marketplace must be economical.

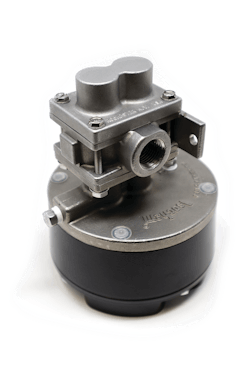

The rapidly growing CBD oil extraction market is an example of a new need for an experienced pump. Botanical extraction and solvent recovery applications require high volume and reliability, and pumps must adhere to sanitary standards because equipment must be cleaned thoroughly between production runs. Pumps such as ISOChem, with new Sanitary Tri-Clamp connections, offer the features, performance and price point that extractors need.

Pump requirements for ethanol extraction

When it comes to CBD oil extraction, ethanol is a preferred solvent. Typical pump requirements for ethanol extraction include:

- Flow from 0.75 gpm (2.8 lpm) up to 55 gpm (206 lpm).

- Pressures up to 150 psig.

- Accuracy — the right mix of solvents enhances yield and product quality.

- Temperatures between -40°F (-40°C) to 250°F (121°C).

- Sanitary connections similar to requirements for food and beverage applications.

- Reliability — pumps such as ISOChem have a 30-year track record in the field.

- Streamlined maintenance — sealless mag drive designs have no seals, which means no leaks and minimal maintenance.

- Price — gear pumps are less expensive than diaphragm or peristaltic pumps when it comes to total cost of ownership.

- Availability — pumps like ISOChem can be provisioned and delivered immediately.

Conclusion

ISOChem pumps are compact, magnetically driven, sealless gear pumps designed to safely handle chemicals and are used in a variety of industrial transfer and metering applications. Within the last 12 months, newly enhanced versions of ISOChem — with new sanitary connections — have seen growth, addressing the needs of botanical extractors.

For more information, visit pulsa.com.