Liquid flowmeters for bioprocessing

Liquid volumetric flow rate is an important process parameter in several bioprocess operations. This includes but is not limited to: depth filtration, tangential flow filtration (TFF), chromatography and perfusion. Different applications require different core flow measurement technologies. Coriolis, mechanical rotary, ultrasonic and electromagnetic measurement principles are discussed.

It is important that the right core measurement technology be selected for each application’s specific requirements. Factors such as cost, availability of single-use products (disposable), flow rate range and potential density/viscosity changes should be considered. Each core technology has positive and negative attributes that must be deliberated. With the right planning and due diligence, the best flowmeter can be selected for each application’s unique needs.

Unique to the biopharmaceutical industry, single-use bioprocessing equipment has become widely accepted technology in a relatively short time. Single-use devices differ from traditional biopharmaceutical process systems in that they are disposed of after each use, as opposed to being cleaned and reused. Disposable devices and components have created market niches and new segments that continue to evolve. The growing demand for single-use equipment has driven development and innovation in the flowmeter industry, with the recent launch of disposable Coriolis and ultrasonic flowmeters.

Coriolis

Coriolis flowmeters utilize the power of the Coriolis Effect to measure the mass flow rate and density of liquids. The operating principle involves a vibration of the tubes through which liquid passes. Sensors monitor and analyze changes in frequency, phase shift and amplitude of the vibrating flow tubes.

Products that utilize Coriolis technology provide high accuracy and precision (usually ±1 percent of reading), wide flow rate ranges and unparalleled ability to handle viscosity and density changes. This is because the flowmeter is technically a mass flowmeter at heart. It follows that when the density of the liquid is known, volumetric flow rate can be calculated. No calibration of the flowmeter is required, even if multiple types of liquids are used. This presents a distinct advantage compared to other technologies.

These flowmeters are ideal for a retentate line in a TFF process since a change in viscosity might occur. Single-use options were traditionally not available because of the unique operating principle, but they are now beginning to appear in the marketplace.

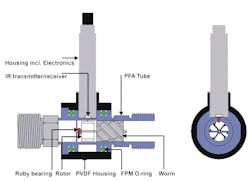

Rotary/Turbine

Rotary flowmeters use a more traditional/ mechanical measurement method where a small turbine (sometimes referred to as "worm") is located directly in the liquid flow path. The turbine wheel is set in the path of a fluid stream. The flowing liquid comes in contact with the turbine blades, imparting a force on the blade surface and setting the turbine in motion. The rotational speed of the turbine is proportional to liquid velocity when a steady speed has been reached.

Rotary flowmeters have two very strong advantages: their low cost and availability of single-use products. While calibration of the pulse constant (K-value) is usually necessary, an averaged value may be found over the flow range of the particular unit. Performance can be improved at specific flow rates by calibrating (determining the K-value) at said flow rate.

Downsides include the inability to handle viscosity/density changes, and their comparatively poor accuracy specifications (±5 percent of reading over the range of the flowmeter). In addition, the presence of particles and debris in the liquid could impair the rotation of the turbine. This would have a negative effect on performance, so these flowmeters are best used after a filter.

Ultrasonic

Ultrasonic flowmeter technology uses high-frequency sound waves to noninvasively measure the flow rate of a liquid. In biotech applications, two main varieties are generally in use: inline designs and designs that clamp on to existing bioprocess tubing.

Inline ultrasonic technology has many distinct advantages. It has high accuracy/ precision — usually 1 percent of flow rate. It is scalable from 1 milliliter per minute (mL/min) or even lower, all the way up to 80 liters per minute (L/min) depending on size. It is noninvasive and thus presents no risk of contamination. It has no moving parts, which means no particle generation occurs. Single-use options are also available. One other advantage of ultrasonic flowmeters is that they can measure the flow rates of a wide variety of liquids if the speed of sound through that liquid is known.

Clamp-on technology allows these flowmeters to simply clamp on to existing flexible tubing. In this manner, the flowmeter has no parts that come in contact with the liquid being measured. This is advantageous because the flow rate of liquids in a disposable tubing assembly can be measured with no reoccurring costs. On the downside, clamp-on flowmeters generally have lower accuracy and precision than inline, and their calibration requires that the process tubing, temperature and liquid be measured.

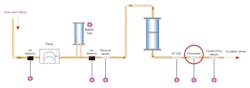

Chromatography. A flowmeter can be used to confirm proper flux reading and flow regime.

Electromagnetic

Electromagnetic flowmeters use magnetic fields applied to the flow tube, which results in a potential difference proportional to the flow velocity. The potential difference is sensed by electrodes aligned perpendicular to the flow and the applied magnetic field. The electrodes must not corrode when in contact with the process liquid, and some electromagnetic flowmeters even have auxiliary transducers installed to clean the electrodes in place. Measurement is independent of density, temperature, viscosity and pressure.

These flowmeters are extremely accurate, have a wide flow measurement range and are less expensive than a comparable Coriolis meter. Electromagnetic flowmeters also have no moving parts or obstructions in the flow path.

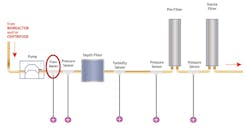

Depth filtration. A flowmeter can be used to confirm pump performance as pressure increases.

The main negative property that must be considered with this particular technology is that the liquid must have some conductance. In general, the liquid must have a conductivity of at least 20 uS per centimeter for the flowmeter to function properly. Another downside is that this technology struggles with low flows. Even the smallest magnetic flowmeters have higher minimum flow rates (≈700 mL/min) than others, which could exclude them from being considered for certain small-scale bioprocess applications. Finally, no single-use options are available.

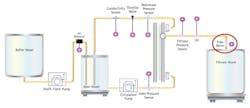

TFF/crossflow filtration. A flowmeter can be used as a totalizer on the permeate line in place of a scale and for retentate flow control.

Conclusion

This article has summarized the different types of flowmeter technology commonly used for bioprocess operations. The bioprocess industry has unique flowmeter needs, in particular for single- use products not present in other industries. This demand for disposable flowmeters resulted in exciting new product releases in 2016.

Above all, in the bioprocess industry it is important that the right measurement technology be selected for each application’s specific requirements, and factors such as cost, availability of single-use, flow rate range and potential density/ viscosity changes should be considered.

John Benson is a design engineer for PendoTECH. He may be reached at [email protected] or 609-799-2299. Visit pendotech.com for more information.