Plant asset management: Automating the final manual frontier

In the aftermath of an incident, some may say that others did not “connect the dots” or understand the true picture. This suggests information existed and may have been collected but did not get to the right people. The effort was too fragmented to be effective.

A process manufacturing plant trying to determine why production suddenly and unexpectedly ground to a halt may go through a similar discussion. The process shut down in mid-operation because of an equipment failure, which should have been anticipated and fixed before a complete breakdown, but nobody could connect the dots and recognize the indications of the developing problem. Device diagnostic data was available but remained lost in log files of the control system where technicians could not access it.

Solving situations like these requires a field device management system — one that can recognize which assets need attention and then provide information on how to fix a developing problem before the situation escalates into a full failure, possibly causing serious and costly damage. This type of system can collect and analyze large amounts of data from a population of smart field devices, including process analyzers and instruments, along with other control devices such as valve actuators and positioners. The system can connect the dots automatically to ensure effective operation without interruptions, supplemented by more effective use of maintenance resources.

Manual versus automated monitoring

Well-trained and experienced technicians equipped with appropriate field communicators (as shown in Figure 1) can do a lot to diagnose the condition of a flowmeter or a pressure transmitter. This involves connecting to the individual instrument and scrolling through perhaps dozens of variables and configuration settings. If they happen to catch a developing problem by recognizing something drifting out of its normal range or if they view an alert message, it might prompt timely remedial action.

Unfortunately, such technicians are rare at many end-user process industry companies, so the likelihood of one being in the right place at the right time is very low. The critical information is available from the instrument, but no one is there to see it, and the failure results.

Imagine posing questions to the production manager of a typical petrochemical plant unit: Why do you have all this automated, computer-driven control system equipment working with all those electronic field devices? Wouldn’t it be better to operate the plant manually?

The question would be considered nonsensical. Responses would undoubtedly include points like the huge number of people it would require to perform repetitive and tedious manual tasks, contrasted with the efficiency and effectiveness of a well-designed distributed control system (DCS). A follow-up question might be harder to answer: So then, why is so much of your asset health monitoring still manual? Shouldn’t it be automated as well?

Capabilities of asset health monitoring solutions

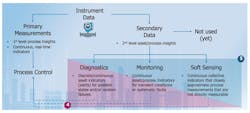

Today’s sophisticated field devices can provide enormous amounts of data. Estimates suggest that the basic primary variable represents barely 3% of the data originating from an instrument or analyzer. So, what does the other 97% represent? (See Figure 2.)

Naturally, it varies based on the type of instrument — a differential pressure transmitter will produce different information than a Coriolis flowmeter or smart valve actuator. But, in general, it includes:

Diagnostics: Discrete and continuous indicators for internal problem states and random failures of the sensor and electronic components. These can be indicated in various ways, including alerts and alarms. Also, device calibration history resides here.

Monitoring: Continuous asset and process indicators, such as process noise, which can indicate changes outside of an instrument’s primary function.

Soft sensing: Secondary, tertiary and even additional variables. These can work individually or in conjunction with other instruments to approximate process measurements not directly measurable.

An effective plant asset management solution is designed to collect the extra data and unlock its potential. When implemented properly, it will improve plant availability and effectiveness while reducing production interruption risk, maintenance time and effort. Critical benefits include:

- Data analysis helps direct preventive maintenance efforts to save time, especially for devices with high maintenance requirements.

- Much faster troubleshooting, eliminating the need for checking individual instruments.

- More effective use of technicians’ time since they can check the status of instruments before performing repairs.

- Data collected and displayed on dashboards for real-time performance, plus captured in histories for later analysis.

Understanding the mechanics

An asset health monitoring system works in parallel with the larger DCS. It gathers the diagnostic, monitoring and soft sensing data from all the smart field instruments and other smart devices using a digital communications protocol — for example, HART or Profibus PA.

Naturally, providing the means to gather data is only the first step. The asset health monitoring system must deliver a basic suite of functions:

- Digital communications to all of the field devices.

- Continuous monitoring and logging of smart device health status.

- Presentation of status data suitable for different types of users.

- Analysis of the installed base to determine the most critical devices.

- Utilize self-checking and performance verification built into devices to extend calibration intervals.

How a system implements these functions is where the various options emerge and allow a plant to customize its solution. One approach is to host it entirely on-site using the plant’s servers for all processing and data storage functions. If required, it is a simple matter to pull device health status through the DCS using a client/server architecture to provide the functions just mentioned. Such systems are modular and highly scalable to adjust to a given site’s needs, and they support incremental adoption if desired.

Since the basic functions tend to be similar regardless of the plant type or size, it is possible to pre-engineer much of the functionality to minimize required end-user integration time and cost. This includes standard desktop workstations and mobile clients. More advanced functions of on-site systems can include:

Sophisticated technologies extend capabilities

The capabilities mentioned so far should be part-and-parcel of any asset health management system. These are the most basic asset health monitoring tools, but even these will put a plant miles ahead of sporadic manual checks. Still, there are many new capabilities that have emerged from industrial internet of things (IIoT) and digital transformation developments to drive advances much further, taking advantage of new networking and communication options.

One of the first differences is where the system resides. There is now no necessity for a plant to maintain this kind of system on its own servers. Cloud-based systems (see Figure 5) are now a reality and used to host a variety of sophisticated applications, including asset health monitoring.

Growing numbers of plants are embracing this cloud-based approach to transfer IT-related maintenance and support to a third-party, allowing the plant to concentrate on production and process optimization rather than IT services. When the system moves to the cloud, the whole implementation can be a solution as a service, including initial setup.

Using today’s networking technologies

The HART protocol has served as the primary tool for sending device diagnostic data for decades, and it remains the leading protocol today. While it has gone through many improvements, its speed and bandwidth remain limited, particularly where a HART solution is retrofit onto legacy hardwired I/O. WirelessHART, whether using a native wireless instrument or retrofitting a conventional HART instrument, offers some improvements, but newer networking protocols, such as Profibus PA, have expanded the range of options and offer improved performance.

Equally exciting is the potential for intelligent field devices that are cloud-ready natively. These include their own SIM card (see Figure 6) so they can send process variables and diagnostic data directly to the IIoT hub. The ultimate result will be an IIoT ecosystem where all data, both process and diagnostic, will be part of one fully integrated system. Plant production, maintenance and even corporate management will be able to access appropriate areas to gather and analyze real-time data to improve the process, reliability and profitability.

Connecting the dots

As important as these new technologies are, it is vital to keep the needs of a given plant in mind and concentrate on the overall benefits that asset health management and other tools can bring, such as:

Reduction of unexpected failures and process interruptions.

- Live view of asset status with easy access, saving time required for routine maintenance.

- Reduction of complexity for technicians, providing greater productivity with less training and fewer tools.

- Less time spent on manual rounds and calibration.

The dots are out there, and the tools to complete the picture for more effective and more profitable operation are ready for any plant to adopt now.

Ben Myers is the product marketing manager for Solutions and Service at Endress+Hauser. Prior to his current role, he spent four years as a process automation engineer on Endress+Hauser’s Solution engineering team. In that role, he was heavily involved with the field engineering and execution efforts of various solutions projects. Myers has a bachelor’s degree in manufacturing engineering technology from Purdue University and a Master of Business Administration from Anderson University.

Ben Myers

Ben Myers is the product marketing manager for Solutions and Service at Endress+Hauser. Prior to his current role, he spent four years as a process automation engineer on Endress+Hauser’s Solution engineering team. In that role, he was heavily involved with the field engineering and execution efforts of various solutions projects. Myers has a bachelor’s degree in manufacturing engineering technology from Purdue University and a Master of Business Administration from Anderson University.