pressure controller

AMETEK STC’s PMT Model 40 Pneumatic Controller employs trusted technology to receive a process variable and control it by transmitting a pneumatic signal. The pressure controller comes in standard control modes of 100% proportional, 200% proportional, 200% proportional plus reset, 75% proportional (positioner only), or 300% PID (proportional-integral-derivative). The PMT Model 40 is also available as an indicating pneumatic transmitter. Mounted close to the measurement point, it transmits an air pressure signal proportional to the measured variable to another indicator, recorder or controller. The Model 40 includes ranges from 5 inches of water column to 3,000 psi and outputs vary from 3-15, 3-27, 6-30 and 12-60 psi.

DP transmitter

The Ashcroft GXLdp differential pressure transmitter with display is designed for monitoring ultra low-pressure applications. The GXLdp is a purpose-built low-pressure DP sensor for pharmaceutical and biotech applications. Available in ranges as low as ±0.05 in. H2O and accurate to ±0.25% of span, the GXLdp incorporates Ashcroft TruAccuracy performance, which ensures precise measurements throughout the range. Offering a backlit LCD and user-selectable analog outputs, the GXLdp provides both local and remote readings. Options include a patented SpoolCal actuator, which provides in-place system calibration capability, as well as optional PNP or NPN switches.

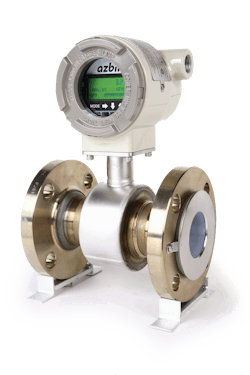

electromagnetic flowmeter

Azbil North America’s MagneWTM Two-wire PLUS+ Loop Powered Electromagnetic Flowmeter provides stable and accurate measurement of corrosive liquids, chemical solutions, drainage/waste disposal fluids, drinking water and wastewater service, and industrial/agricultural water applications in pipe sizes up to 8 inches. The loop-powered MagneWTM Two-wire PLUS+ replaces outdated two-wire technologies. The flowmeter detector has a smooth (0.05 µp) mirror-finish PFA liner that prevents dirt and residue buildup. The liner is mechanically locked to a punch plate frame, which prevents deformation and peeling caused by temperature and pressure changes. The flowmeter is FM/CSA approved non-incendive for use in Class 1 Division II hazardous locations.