Measurement instrumentation for successful EV battery manufacturing

To reach net-zero carbon emissions, many countries and companies aim to reduce emissions from the transportation sector, which relies heavily on fossil fuels and accounts for about 20% of global CO2 emissions. Electric vehicles (EVs), powered by green electricity instead of gasoline or diesel, will be central to this effort. With policies phasing out internal combustion vehicles, zero-emission vehicles, primarily electric, are crucial for success.

The International Energy Agency states that two billion EVs are needed by 2050 to reach net zero goals, with most running on rechargeable batteries. Lithium-ion (Li-ion) batteries are preferred for EVs due to their high energy density, which allows vehicles to travel farther on a single charge. As Li-ion batteries become more advanced, manufacturing processes need to improve in terms of quality, safety and reliability.

This article covers battery component manufacturing and recycling, and it will highlight the role of automation and advanced measurement instrumentation to optimize these processes.

Manufacturing steps

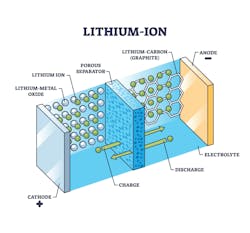

Battery manufacturing is a complex mix of process and discrete operations, with chemical production side-by-side with the robotics used for coating application and physical assembly of cells. A typical cell includes an external case for insulation and support, a positive cathode side, a negative anode side, an electrolyte where electrochemical reactions occur and a separator to prevent the poles from touching, which would cause a short circuit (Figure 1). Charging a cell moves lithium ions through the electrolyte from the cathode to the anode, and vice versa when discharging, with the separator allowing ion movement, while providing electrical insulation.

The anode is usually a copper foil coated with graphite, which is ground to a specific size, made into a slurry, applied to the copper and baked to bond, while maintaining conductivity and porosity.

The cathode, more complex and variable by manufacturer, often comprises alloys like lithium-nickel-manganese-cobalt oxide or lithium-iron-phosphate, requiring high purity to avoid contamination. It is processed into a powder and applied to a metal foil.

The electrolyte, a liquid enabling lithium ion movement, and the separator, are critical for battery function. Electrolytes mix lithium salt, mainly lithium hexafluorophosphate, in an organic solvent, with additives to stabilize ion flow and protect the anode and cathode. These components together form the intricate architecture of Li-ion cells, each playing a crucial role in the battery’s performance, safety and efficiency.

Making components for Li-ion cells involves various gels, pastes, slurries and liquid coatings — each of which must be applied very uniformly to a variety of surfaces. All of these are produced in batches, making the need for consistency paramount.

Given the nature of this competitive and complex industry, manufacturers must use advanced measurement instrumentation to monitor quality at every stage so they can maintain production efficiency and minimize waste. This requires:

- Limiting variability among batches caused by raw material inconsistency.

- Monitoring and controlling the progress of a batch from start to finish.

- Avoiding excess equipment wear and subsequent loss of precise control due to damage caused by corrosive and abrasive materials flowing through the production process.

- Protecting personnel, equipment and the local environment by maintaining control over and safe storage of corrosive and toxic products.

- Building in production flexibility to meet customer requests for different battery component types and proprietary recipes.

Here are some practical considerations for ensuring consistent product quality, production safety and equipment reliability.

Monitoring quality

Ensuring quality in batch manufacturing hinges on recipe consistency, along with the precise measurement and analysis of ingredients. Achieving this level of precision and reliability requires a robust toolkit of measurement technologies and strategies to address the inherent variability in material properties and process conditions.

Each ingredient must be added to a mixer or reactor in the correct amount, and a leading approach for this measurement is a mass flow meter. Technologies like the Micro Motion ELITE Coriolis Flow and Density Meter (Figure 2) stand out for their ability to directly measure the mass flow of liquids, slurries and gases, unlike traditional methods that infer mass flow from volumetric measurements. This capability is crucial for ensuring the correct quantity of each ingredient is added to the mix, especially when dealing with materials whose density may vary with temperature or composition. The meter’s ability to also measure density provides an additional layer of control, enabling precise formulation of the batch mixture.

Maintaining the correct pH level is vital, particularly in processes that involve highly acidic or reactive materials. Emerson’s Rosemount 372 Hydrofluoric Acid Resistant pH, RBI pH/ORP, 3400HTVP pH/ORP and 3500VP pH/ORP sensors are engineered to deliver accurate pH measurements in these challenging conditions, ensuring the chemical reactions within the batch proceed as intended. Reliable pH control is essential for producing consistent, high-quality outputs, especially with these types of chemical reactions, where the product quality is directly influenced by the acidity or alkalinity of the mixture.

Viscosity control is another critical aspect of quality monitoring, particularly for ingredients applied as coatings, or for those that must have a specific flow characteristic. The Micro Motion Fork Viscosity Meter allows operators to monitor viscosity in real-time alongside density and temperature, facilitating immediate adjustments to the process to maintain the desired material properties. This real-time monitoring and adjustment capability is critical for processes where the viscosity of the material impacts the efficiency and quality of the coating or blending operations.

Conductivity measurements play a pivotal role in the quality control of electrolytes. Rosemount 228 Toroidal Conductivity sensors work well for measuring the conductivity of highly conductive liquids, including the corrosive or abrasive solutions common in battery manufacturing. Conductivity is a direct indicator of the electrolyte’s ability to facilitate ion flow, which is critical for the battery’s performance.

Batch volume verification through non-contacting radar level transmitters, such as the Rosemount 5408 Level Transmitter, confirms that the total volume of the batch aligns with production specifications. This step is crucial for validating the completion and consistency of the batch, ensuring that no deviations have occurred during the mixing or reaction stages that could affect the final product volume.

Ensuring safety

Li-ion cell manufacturing requires the use of highly reactive and hazardous materials, necessitating robust safety measures to prevent injuries and protect equipment. Li-ion battery production involves handling corrosive, toxic and flammable materials, underscoring the need for comprehensive safety protocols.

For gas and vapor detection, facilities employ advanced toxic gas detectors, such as Emerson’s Rosemount 928 Wireless Gas Monitor and Rosemount 925FGD Fixed Gas Detector (Figure 3). These detectors are crucial for identifying hazardous gas leaks, ensuring a rapid response to mitigate potential dangers. The Rosemount 975UF Flame Detector is another essential safety tool, capable of detecting flames quickly by sensing radiant energy, thereby helping to prevent further safety complications.

Occupational safety measures include the implementation of safety showers and eyewash stations throughout manufacturing sites. These can be monitored by Emerson’s TopWorx Safety Shower and Eyewash Station Monitoring Kits, which alert control rooms when activated. This ensures that workers exposed to chemicals receive immediate assistance.

Process safety in Li-ion battery manufacturing also requires close attention to higher risk measurement and control applications as these pose increased safety risks to workers and the environment should a failure occur. To address these and related issues, manufacturing processes should incorporate safety-certified instruments capable of withstanding such conditions. Emerson has a wide range of safety instruments certified to IEC 61508 (Figure 4), and these are integral to the safety-instrumented systems designed to prevent accidents. These instruments monitor a range of process variables, from pressure and temperature to flow and level, ensuring operations remain within safe parameters.

Safety in Li-ion battery manufacturing encompasses a wide array of measures, from toxic gas and flame detection, to occupational safety protocols and process safety systems. Each layer of protection contributes to a safer manufacturing environment, minimizing risks associated with the handling of hazardous materials, while ensuring the well-being of personnel and the integrity of manufacturing equipment.

Improving reliability

Modern process instrumentation is key to enhancing reliability in Li-ion battery manufacturing, including diagnostic capabilities that alert reliability teams to potential issues. This foresight allows for proactive maintenance planning, helping to prevent production disruptions. Smart Meter Verification software, which is compatible with a variety of Emerson flow meters, is particularly valuable because it offers real-time meter and process performance monitoring, with historical data review. This feature simplifies meter calibration timing decisions and, when integrated with digital control networks, reduces the need for manual field checks.

Corrosion and erosion pose significant risks to manufacturing equipment due to the reactive chemicals used in production. For continuous monitoring, Emerson’s Rosemount Wireless Permasense ET410 Corrosion and Erosion Monitoring System provides real-time measurements of pipe or vessel wall thickness, allowing for immediate maintenance actions to ensure equipment integrity.

The mobility of reactors in some manufacturing processes creates challenges for wired instrumentation. Wireless devices, like the Rosemount 2051 Wireless Pressure Gauge and Rosemount 248 Temperature Transmitter (Figure 5), offer a solution by eliminating the need for frequent connection and disconnection. This enhances flexibility, reduces the risk of equipment damage and simplifies installation, leading to significant cost savings compared to traditional wired devices.

A growing number of field instruments necessary for the process manufacturing side of the plant are available with Bluetooth technology (Figure 6), adapted for industrial environments so it can be applied to field devices deployed in process manufacturing facilities. Using this approach, Bluetooth wireless communication supports viewing of diagnostic information and easy configuration, without the need for a wired connection.

Traditional communication with a field device normally involves opening the housing and clipping on leads to a communicator. This exposes transmitter internals to potential environmental contaminants, and can pose a safety hazard for an operator, who must reach the transmitter, regardless of where it is located. This may involve using a ladder, climbing out on a catwalk or installing temporary scaffolding.

Recycling as the future

As early EV batteries reach their end of life, the focus shifts to recycling to recover lithium and other metals, reducing waste and the demand for virgin resources. Current recycling processes include hydrometallurgical or pyrolysis methods to break down batteries, extracting metals like lithium, cobalt, manganese, copper and nickel. These metals are then refined for reuse. Some direct recycling methods unroll the battery to renew individual components.

Recycling presents challenges similar to manufacturing, such as maximizing material recovery with inconsistent feeds, and controlling the batch process from start to finish. Avoiding equipment damage from corrosive materials and ensuring safe storage of toxic products are also concerns. Many of the instruments used in battery manufacturing are applicable to recycling.

For example, magnetic flow meters, like the Rosemount 8700 Series, equipped with Smart Meter Verification, ensure reliable acid measurement in leaching processes. pH sensors are vital for optimizing metal recovery because they provide the measurement data needed to adjust the leaching solution's pH. Additionally, Rosemount 5408 radar transmitters are well suited for level monitoring in corrosive environments, and corrosion monitoring is advised to ensure equipment integrity and longevity.

A technology partner for today and tomorrow

Collectively, these advanced measurement and monitoring technologies empower manufacturers to make informed, real-time adjustments to their processes, significantly reducing the variability that can compromise product quality. By leveraging these tools, manufacturers can more effectively manage the challenges presented by raw material inconsistencies, complex chemical reactions and stringent product specifications.

Implementing these technologies enhances operational efficiency and product consistency, and it also plays a crucial role in conserving valuable resources. Through careful monitoring and control of batch processes, manufacturers can ensure that they are making the most efficient use of these critical materials, reducing waste and supporting sustainability objectives.

With measurement and automation technologies at the heart of most production steps, organizations across the entire lithium value chain can benefit from partnering with an expert automation technology provider that can help them optimize operational performance and produce high-quality Li-ion batteries at scale.

Michael Machuca | Chemical industry marketing director for the measurement instrumentation portfolio at Emerson

Michael Machuca is the chemical industry marketing director for the measurement instrumentation portfolio at Emerson. He has been with Emerson for over 18 years in various product management and marketing roles supporting industrial process measurement applications in the oil & gas and chemical industries. Prior to joining Emerson, Machuca designed oil field equipment for subsea applications during his tenures with Cameron and Dril-Quip. He holds a Bachelor of Science in Mechanical Engineering from the University of Houston.