Calling something an absolute, gauge or differential pressure transmitter is matter of perspective. Measuring pressure — the force applied to an object per unit of area — is relatively easy to do. We use terms like “PSI,” “atmospheres” and “inches mercury” to describe how much force is acting at a point in space. But does knowing the pressure at a given point in a process yield any useful information? Quite a lot, actually. This article is the first in a four-part series that explores the many useful ways pressure measurement can be used.

Before discussing how pressure measurement can help control industrial processes, it is important to have a basic understanding of pressure and force. These terms are often used interchangeably, but they are not the same. By definition, force is defined as the mass of an object times its acceleration — e.g. gravity — and can be thought of as the push or pull on an object. Pressure is the amount of force applied perpendicularly to a given area, and the units we use to express pressure are found by dividing that force by unit of area. Perhaps the most well-known unit of pressure, at least in the United States, is “PSI,” or “pounds-force per square inch.” Other units of pressure include Pascals (Pa), Atmospheres (atm), bar, inches mercury and inches water column. These different units describe pressure in various real-world applications.

Differences in pressure

Why does industry differentiate between absolute, gauge and differential pressure? The answer depends on a reference point, and while the terms are similar, they are not interchangeable.

- Absolute pressure is the sum total force per area exerted on a surface of an object relative to a perfect vacuum. It is equal to gauge pressure plus atmospheric pressure.

- Gage pressure is the force per area exerted on a surface relative to the ambient air pressure around it. It is equal to the total, or absolute, pressure minus atmospheric pressure.

- Differential pressure is the difference in pressure between two points. This sounds like a simple definition, but it is more complex than gauge or absolute pressure because two variables — high-side and low-side pressure — are needed to calculate it.

Measuring pressure

Field instrumentation such as gauges, sensors and transmitters are used to measure pressure. A typical industrial pressure transmitter consists of a meter body and a head.

The meter body is an elaborate construction of flanges, diaphragms and fluids, all designed to transfer the physical variable (pressure) to the sensor. It is essentially a fluid-filled chamber bisected by a center diaphragm, and encapsulated by covers, process heads and flanges. On either side of the center diaphragm are barrier diaphragms — one on the low-pressure process side, and one on the high-pressure process side — which are in direct contact with the process media via process connection points. As pressure is applied to these process connections, it is transferred to a piezo-resistive sensor, which converts the physical pressure measurement into an electrical signal such as millivolts and then sends the information to the electronics in the head.

The head is a metal case that contains electrical boards, LCD indicators and other components that convert, standardize and send the electrical signal to a receiver or controller, typically as a 4-20mA, 1-5V, or 1-10V analog signal. Many advanced transmitters also use digital communications protocols such as HART, DE, Modbus or BACnet to talk to the receiver.

Different instruments measure the different pressures discussed.

- In a gauge pressure transmitter, the high-pressure side is typically connected to the process, and the low-pressure side is "vented" to atmospheric pressure. This venting can be accomplished in a variety of ways, but essentially means there is an open path from the low-pressure barrier diaphragm to the atmosphere. Thus, when the process pressure is applied to the high-pressure side of the diaphragm, it is being compared against atmospheric pressure.

- In an absolute pressure transmitter, instead of "venting to atmosphere," there is a chamber over the low-pressure barrier diaphragm which is evacuated and sealed so the reference pressure is a full vacuum. The process pressure that is connected to the high-pressure barrier diaphragm is thus compared against that full vacuum, or 0 psia.

- In a differential pressure transmitter, the high- and low-pressure sides are connected to the process at different points, and the pressures at these two points are compared to find the difference between the two. Thus, the difference in pressure between these two points is the "differential pressure."

Using pressure

Engineers turn pressure data into useful information to help control every aspect of an operation, from energy management to critical process control to safety and more. Interestingly, level and flow measurements can also be derived from pressure. Future articles will explain more on how this is done, but a handful of practical examples follow.

Measuring pressure for quality and safety

Compressed gasses are essential to many manufacturing processes — loss of pressure could result in quality defects and production downtime. Accurate and consistent pressure measurement ensures processes are stable and predictable.

Excessively high pressure is inherently dangerous — tanks, ducts and pipes can burst and cause catastrophic damage and injury. Measuring pressure can be used as a safety measure — processes can be automated to shut down if pressure reaches some critical high or low point.

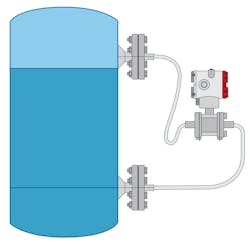

Measuring level for industrial process control

The level of fluid in a tank can be found by measuring hydrostatic pressure. If a fluid is at rest (no pumping, draining or swirling to generate dynamic pressures), the only pressure at a given point comes from the weight of the column of liquid at that point (and atmospheric or tank pressure, if applicable). If the density ρ (rho) of the fluid is known, it is possible to calculate the height of a column of liquid between two points. Specifically, the difference in pressure ΔP (Phigh – Plow) is equal to the density (ρ) times the height.

ΔP = ρ x Height

So, if the density is known, and pressure can be measured, the height (or level) is derived as:

Height = ΔP / ρ

In this way it is possible to calculate how much fluid is in the tank, set alarms and otherwise tell the system to take some action, such as turning a pump on or off.

There are many different ways to take pressure readings at fixed points on a tank. Always check with an instrumentation and controls engineer and the instrument manufacturer to ensure the pressure transmitters are set up properly. Some examples of using pressure to calculate tank level include:

- Wastewater lift stations: Liquid level transmitters control pumps to empty wastewater storage facilities when the level reaches a critical high point.

- Pulp and paper manufacturing: Transmitters measure the amount of diluted black liquor in evaporators used in pulp and paper mills.

Measuring flow

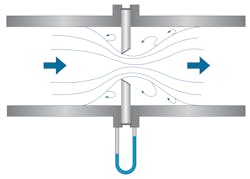

Fluid flow measurement traces back to work done by Daniel Bernoulli in 1738 that states that as a process fluid flows through some restriction in a pipe, the velocity of the fluid increases, and static pressure decreases. This pressure drop can be used to calculate the velocity and flow. The restriction in the pipe is generally referred to as a “primary element” — some physical obstruction that is placed in the tube that the fluid must flow around or through. Pressure taps placed just before and after the primary element allow impulse lines to carry the pressures to the transmitter, which determines the differential pressure and converts it into an output signal.

Measuring flow via differential pressure (DP) does have some drawbacks such as pressure drop and time-worn primary elements, but DP flow still accounts for about a quarter of all flow measurement in the field. Some examples include:

- Steam plants use DP to measure the steam generated by boilers to ensure load matches demand.

- Specialized air handling units (AHUs) use DP to measure the amount of hot or chilled water passing through coils to ensure energy efficiency in an HVAC system.

Conclusion

Quality, production and safety across every industry depend on real-time, accurate process measurements. If a PLC or other central control system is the “brain” of an operation, field instruments such as pressure transmitters are the nerve endings on fingertips, feeding data back to the brain.

Pressure measurement yields many types of invaluable information, provided it is done correctly and consistently. Field instrumentation manufacturers and instrumentation and controls experts in process automation use pressure to insure consistent, safe and profitable operation of their businesses.

Francis “Mac” Kern is a regional sales manager for Azbil North America Inc. based in Denver, Colorado. He holds BSE-ME and BSE-IOE degrees from the University of Michigan at Ann Arbor and an MBA from DePaul University. Kern has worked in various roles at Azbil, with a current focus on digital marketing content management. He can be reached at [email protected].

Gauge versus absolute pressure transmitters — why one over the other?

If the only difference between a gauge pressure transmitter and an absolute pressure transmitter is 14.7psi, why do we need separate transmitters? As with many design decisions, the answer comes down to cost and accuracy. Absolute pressure transmitters are referenced to a fixed absolute zero pressure that does not change based on where it is installed, whereas gauge transmitters are referenced to atmospheric pressure, so there is variation induced by changes in elevation and weather — they are inherently less accurate than absolute pressure transmitters. Therefore, absolute pressure is more often used for critical process measurements such as compensated gas flow measurement and in vacuum applications because they are not affected by atmospheric pressure. However, absolute transmitters are typically 25-35% more expensive and require more effort to calibrate.

What is the difference between a pressure sensor, transmitter and transducer?

The words sensor, transmitter and transducer are often used interchangeably in various industries, but this can lead to confusion since they are in fact functionally different instruments.

- Sensor — A device that makes contact with the process media, measures a change in a physical variable (such as pressure) and provides a measurable output signal (such as PSI).

- Transducer — A device that converts energy from one form to another. For our purposes, it converts pressure or force into an electrical signal such as millivolts.

- Transmitter — A device that standardizes that electrical signal (typically into 4-20mA, 1-5V, or 1-10V signal) and sends it to a receiver.

About the Author

Mac Kern

Western Regional Sales Manager — Azbil North America/VorTek Instruments

Francis “Mac” Kern is a Regional Sales Manager for Azbil North America, Inc. based in Denver, Colorado. He holds BSE-ME and BSE-IOE degrees from the University of Michigan at Ann Arbor, and an MBA from DePaul University. Kern has worked in various roles at Azbil, with a current focus on digital marketing content management. He can be reached at [email protected].