The path to a successful vibration monitoring program

The industrial world is no longer about singular solutions. While condition monitoring is desired, device or software interoperability and connectivity are key to integrating measurements from assets. Many may not know where to start, let alone which technologies to choose. However, there’s light at the end of the tunnel.

Solutions are not only calling out their functions but also becoming more integrative than before. Third-party software works with manufacturer devices and vice versa; although not industry-wide, the trend is growing. As it continues to seep into more industrial sectors, connected reliability and the many types of condition monitoring become more accurate, improve operation availability and decrease bottom lines.

The not-so bumpy road to reliability

Machinery used in the storage and transfer of liquids, slurries or gases work hard. While not quite the same as a conveyor at a quarry, these machines are constantly running and moving vast quantities of material. To keep these assets running well, a connected reliability program with condition monitoring sensors and end-to-end data sharing is required.

Pilot programs will show measurable results and a path to implementing new IIoT technologies into existing workplaces. They are imperative to a successful integration. However, they are only a part of the journey to improved reliability. Other tasks can include:Complete an asset criticality assessment: Ranking each asset by its necessity to operations will help teams prioritize maintenance and repairs. Items more critical to production have a higher prioritization — a required task for determining which assets are critical and which are merely bad actors.

Audit existing networks: Knowing how strong a network signal or what kind of signal blockers exist within or around locations is vital to determining which IIoT devices will work. Knowing which one requires a cellular versus Wi-Fi hotspot will affect the devices selected.

Ensure employees understand current practices: Retraining should never be thought of negatively, but as an opportunity to brush up on knowledge or skills or hear about updates to processes and practices.

Determine the best technology for your needs: Given the assets you have in your pilot, the network connectivity and employee capability help guide device selection. Vibration monitoring devices should be always-on sensors that continually take measurements and aggregate them to a cloud-based database.

Train employees on new software and devices: With devices chosen, select who will be trained on the new systems and technology. Train-the-trainer moments help solidify and transfer knowledge or skills, ensuring entire teams are up to date.

Gain feedback from users: Reach out to them for feedback. If something is not working, change it before the program gets larger.

Gather pilot data for basis of expansion: All of the asset data, maintenance tasks, etc., can be used to prove your pilot program’s success. Gather these and take concepts to leadership for approval. They will appreciate the savings to the bottom line.

Expand your pilot organization-wide: Wash, rinse, repeat. In manageable chunks, expand the program to include more equipment, different locations or production lines or even expand the program’s capabilities.

Pilot programs bring good vibes

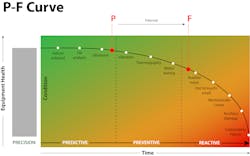

Vibration monitoring is seen as a “Goldilocks zone” for maintenance and reliability programs. The potential failure (P-F) curve offers a glimpse of an asset’s condition from the time it is engineered/installed to the moment it fails. It is not an actual timeline or flow of degradation but does provide value by showcasing when each monitoring technology could be used during the process.Ultrasound and oil analysis offer insights very early (some say too early) in the P-F curve, while physical changes are too late in the maintenance cycle to avoid breakdowns. Vibration provides advance warning with plenty of time to attend to insights with action.

So, vibration is the “just right” for the forewarning-to-failure ratio but getting the right data from the vibration device is key. An organization could gather all the data in the world, but still not be able to read it and make data-based decisions thereof.

Selecting the right assets (via the asset criticality assessment), sensor location on assets, measurement periods, etc., will affect the program. Boil down the data to what you need to learn about — pumps, motors or other gas/liquid machinery — to ensure production still flows.

Manufacturers should also offer training or on-site resources during pilot planning and execution. This allows you to ensure your initial setup is top-notch, while training the trainer within your own organization. Further program expansions or pilots will then be much easier to deploy with an internal expert.

For nonrotating equipment, fill the gaps in data by integrating a power monitoring program into your connected reliability plan.

Immediate results make programs buzzworthy

Organizations will start to see benefits and returns while the pilot program is underway. Vibration monitoring measurements provide a snapshot into asset health. More intense vibrations mean assets are closer to a fault and require attention; normal or acceptable vibrations can wait until other, more urgent tasks are attended to.If vibrations from a pump are normal, then maintenance can be held off until conditions require it. This frees workers to attend to the backlog of maintenance repairs or other critical tasks. When assets exceed indicated thresholds — usually setup during installation of devices — IIoT-connected devices should send an alarm to a user’s smart device, giving teams instant notification of impending faults.

Leveraging asset criticality prioritization with aggregated data from automated, always-on vibration sensors or other monitoring technologies allows teams to gain insights into an asset’s health or current conditions, as well as plan maintenance based on operational or production needs. Manual rounds and clipboard transcriptions become things of the past, resources are used in more responsible ways, which reduces costs, and the backlog decreases, ending wasted resources used to limp assets along.

A connected reliability future is here

Vibration monitoring is only one aspect of a full-fledged connected reliability program — like the road signs on the highway. Data from monitoring influences the path taken, but it is not the only, or even the most important, aspect of connected reliability. It takes a lot of other reliability efforts and plenty of planning to create a network of data, systems and teams that have zero barriers to accessing information.

Migrating to an interconnective and interoperable vibration monitoring program that works within a connected reliability workflow allows teams to better manage asset life cycle by aggregating data and gaining insights, improves resource usage as well as reining in spending on prematurely used resources, and transforms organizations into industry and world leaders.